Search the Community

Showing results for tags 'BuWizz'.

Found 175 results

-

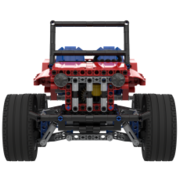

Hoonitruck drifter with 2 BuWizz Motors

Another Brick in the World posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi guys! As some of you may know, I'm a huge off-road fan. I never really saw the potential in on-road, and sometimes found it boring. But then, I watched a few drifting videos and instantly saw the potential to make a LEGO drifter. I got in touch with my friend @N1K0L4, which is an on-road fan and has experience in the field, and sent me a couple of chassis designs. I obviously chose the most overpowered one You can check out N1K0L4's chassis here, and the full rebrickable post here. Now, let's go with the details: Features RWD with 2 BuWizz Motors Steering with a C+ L motor Realistic looking bodywork resembling Ken Block's Hoonitruck All fueled-in with a BuWizz 3.0 unit For me, one of the most important functions is the drivetrain. It's built in a very clever way with the 2 BuWizz motors leaving just enough space for housing the BuWizz 3.0 unit. It's RWD, which isn't true to the real-life counterpart, but N1K0L4 is working on a new version with AWD and it's looking very promising! updates about the AWD version will be made in this topic. To finish it off, the steering was added, using a rack and pinion setup to have as little slack as possible as that's a key factor in mini-racers. It's steered with a C+ L motor as said earlier, with this being my first time using C+ electronics. I have mixed feelings about it, but more on that later. The bodywork was an interesting one. I wanted it to be as accurate as possible to the real deal, but I had to use white mudguards as LEGO for some reason doesn't produce them in black. Still, they didn't spoil too much the body for it to be recognizable, so I'm happy with it. Still, it was somewhat flimsy and would tear to pieces if I hit a jump wrong. Still, N1K0L4 has also addressed this while still making it more accurate. I guess union makes strength For the video, I wanted to use a different setting in comparison to my other videos, as it's a very different model to the previous ones. I chose to go to a skate park, as it had some smooth concrete sections for drifting, and ramps to do some jumps, which is exactly what this model was built for. The model handled excellently in spite it's RWD, although I'm not used to models this fast, so I hit jumps wrong dozens of times. There are some included in the video, but many weren't included, but I'm considering making a bloopers video. How would you guys feel about that? However, the parts didn't like the skate park, as concrete is very abrasive to abs plastic. The splitter was melted and torn to pieces, and the tires lost most of their thread in the process, up to the point where I had to use to sets of them to record the video. I guess I'm a bit of an aggressive driver, but you should be aware of that if you build this model. About the C+ electronics, I'm not fully sold out. They do have some pros, like the more convenient shape of the motors or the faster response, but they show some disadvantages when taken into closer inspection. The steering trim was a pain to get right, and even when that was the case, it still veered ever so slightly to one side. I think it has to do with the fact that the 0 position is digital and not physical. Still, I'm considering using them in future build mostly because of the easier integration, but will probably stick to PF servos for faster models as they return to center more accurately. Feel free to post a comment about what your thoughts are about it, and see you in the next one!- 4 replies

-

- hoonitruck

- lego

-

(and 8 more)

Tagged with:

-

4x4 Raid Buggy V2 with 2-speed Gearbox and BuWizz motors

Another Brick in the World posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hello again, Back in March 2023 I started my YouTube channel with my Raid Buggy. Granted, it look somewhat crude and it was quite slow, but it was my first model with BuWizz motors and bricks so it has a special place my heart. Recently it was the 1 year anniversary of it, and I decided to make a remake of it to prove some how much my LEGO building skills have changed and to honor the original model and channel. So enough with the backstory, let's get to the details: Features 4 Wheel drive with a 2-speed gearbox steering with double steering racks Soft double-wishbone suspension Working gear stick Bodywork built to resemble the original model One of the things that I wanted to show with this model was that you don't necessarily need 4+ BuWizz motors in order to make a good fast off-roader. For this, I decided to make use of a 2-speed gearbox, which has a low gear with the same gearing as the Raid Buggy V1 and the high gear which is some 67% faster (6.2 km/h). The gearbox design was heavily based off @Zerobricks's excellent Simple Off Roader but modified to fit my needs. Another benefit of this is that it has a neutral gear, which is very useful for downhills. From then, I finished it off with the axles of my Monstermog and the chassis was done! from there, I had to build the bodywork, the part that I had been dreading the most For me the body was a very important part, as I wanted to make it reminiscent of the original yet it would have a more sporty look and a stronger construction. Just like the first model, it uses many connectors in @Attika's characteristic style. In the end, the bodywork suffered many changes but I consider them for the better, as it now has a more imposing look and a much more sturdy connection so it can be rolled over without having to fear of breaking it. And now a few more images: The model ended-up being a very good off-roader, with a somewhat high speed (6.2 km/h) yet with some torque left for harder off-road. I pretty much had no issues with it, except the front open differential which sometimes got in the way when off-roading in the low gear. It's otherwise a model more focused on high-speed on uneven terrain so I'm happy with it If you would like to build this model, you can download the .io file at rebrickable here. And as always, here's a YouTube video containing some off-road footage, functions showcase, and some nice Punk Rock music Feel free to post a comment about what are your thoughts about it, and see you in the next one! -

Fluffy, an oversized proof of concept

Attika posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hello there, it's been a while.... I wasn't entirely inactiv in the last couple of years, but I had a technical difficulty to make videos. Without videos there's no point to post anything, so there it is,a big chunk of can't do attitude... However it has changed. The subject of this topic is on an exhibition now and I was forced to overcome my lazyness and make that camera roll again. To the subject: How did I get this low? I've bought 2 sets of this Audis back in the day as I've found it being a good value for money as a partpack. As a sideproduct I had enough of the curvey panels to get physical on an old idea, the barrel like structure you see on the thumbnail above. Luckily my past granted me an unlimited supply on connectors. As long as it existed only in my head, I was quite sure it is too flimsy and fragile to bare any load, let alone to coop with the centrifugal force that comes with the rolling motion. While rolling around the empty barrel on my desk I figured I could use a somewhat symmetric structure to apply an inward tension on the barrel and that's gonna keep it from falling apart. The fact that the barrel made out of 16 panels made it kinda obvious what symmetry should I use. I put my bet on a 4 spoke solution. The barrel would give a 15.5x15.5 stud square to work with, so I've used a 15x15 structure to reach that inward tension. It is well within the reversible flex of abs, yet enough to keep the circle from pulling apart The next challenge was the attachment of the wheelhub. There is an interlocking frame that holds the sprocket wheel in the center of it.... And so to prove the concept, I had to build a whole chassis around it. For those of you who can benefit from a studio file, here it is: https://drive.google.com/file/d/1uX-avOl3x6DPfGcx_IF1nKzRtAwWqvu6/view?usp=sharing As a sidenote, the io model is a simplified version when it comes to the chaos I've built in the mid section of the frame to avoid the twisting of it. Also I took advantage on the natural flex of the connector body which could not be replicated in the rigid studio enviroment. But I can assure you, no parts were harmed. Some of the data: It is about 70 cm long and 50ish wide, has the ready to run mass of 2.7kg. Uses 4 buwizz motors to drive, a PU L motor to steer and 2 buwizz 3units to get the sparks. Originally I've built it using the slow outputs but on the 2nd testrun I had to try the fast outputs on the motors and it took it like a champ. Although it altered the driveshaft geometry slightly, it had next to no effect on the practical usage. I can't emphasise enough that this car is only a tool to prove the concept of the wheel here. To keep the buwizz units from shuting down, the max output is reduced to 92 percent. This setup gave me fun to play dinamics and a very generous 10 minute + runtime. Way more on both than what I've expected at the begining. The chassis I suppose speeks for itself, nothing out of the ordinary. The lower wishbones have a wider base towards the chassis to deal with the frontal forces. No drivetrain -no loss of efficiency on gears. One thing to mention to fellow builders: I had so much room to work with inside the wheel, when I was building the front suspension, I couldn't stop smiling how effortless to do a "proper job". Meaning caster, camber, and ackermann geometry... Nothing else really comes into my mind, but I'm sitting on this for a half a year now,so I might just be numb about otherwise important details. I'm happy to answer your further questions. Thanks for your attention and feel free to give a honest feedback. My psychiatrist prepared me for situations like this. PS: If you find the panels on the wheels looking suspicious, that's the tape I applied on them to save them from the scratches (as much as possible).- 19 replies

-

- rc

- brickbuilt wheel

-

(and 1 more)

Tagged with:

-

.thumb.png.ac42fe5bf808b68722d021abc3bc5691.png)

[MOC] 1970s rc rally car

Aurorasaurus posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Inspired primarily by the Opel Manta 400, I've made my own RWD rally car. It features independent front suspension, and a rear live axle using the big ball joint and a metal U-Joint. Its propelled by 4 buwizz motors and steered by one C+ L motor. Some late WIP photos Earlier WIP photos Problems Because of the narrow wheelbase and relatively high center of mass due to high up buwizz units, the model easily rolls when driving at high speed and cornering. I was lazy with the design of the suspension; the front is too soft and the steering is inaccurate because I am using Instead of the newer parts with longer arms for steering links. This allowed me to fit the wheels inside the body, though. The rear suspension is too hard primarily because I got lazy and wanted it done, after about 8 hours on the model I was getting bored. The bodywork has some parts that could be white if I had the parts in white, but those parts are quite small. If you have any questions, feel free to ask. As of right now I still have the model assembled. Thank you for reading. -

1:12 Audi S1 e-tron

Zerobricks posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Here's a fun little project I came up with while trying to find a way to build the smallest AWD model with independent suspension. Having found a solution I decided to build a representation of the awesome Audi S1 e-tron using a 3D STL file purchased online. I set myself the following functionality and features as goals: All Wheel Drive Proper independent suspension on all wheels Each wheel powered by one BW motor Working steering wheel Detailed interior with proper seats and details Easy access to the 2 BW bricks powering and controlling the model Deisgn the body to be accurate to the 3D reference, yet robust Part count of 1200 or less With the goals set, I came up wih this prototype in LDD: The next photo is showing just how close the model is following the reference 3D model in green: And here's the model in real life, built out of exactly 1200 pieces: I took full advantage of the new micro panels, so there are almost no flat/straight surfaces in the model: Finally the belly photo showing how I used brick-built CV joints in order to keep suspension and drive system as narrow as possible. And yes, those are rings from LOTR sets I will post better photos and a video as usual when I find the time. For now I can say that this thing has a really high power-to-weigh ratio and it can easily spin all wheels when accelerating.- 20 replies

-

Simple Off-Roader + Instructions

Zerobricks posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Many people have been asking me for a simple, easy-to build and most importantly cheap Off-Roader. When I started this project, I've set myself the following guidelines: Use a single BuWizz 3.0 and "only" 2 BuWIzz drive motors Implement a 2 speed gearbox Maximize the ground clearance by using a pendular axle (this way the independent suspension doesn't have to loose ground clearance when going over obstacles) The model has to be built from under 500 parts All the parts have to be standard and in current production Keep the number of different parts as low as possible Use color coding to simplify the building process Design the model so that it can easily be modified by other builders Create proper building instructions And this is what I came up with in the end: I managed to successfully realize the all the planned functionality, features and more: All wheel drive 2 speed gearbox Pendular front axle Independent suspension on all wheels Openable doors for easy acces to the charging port Interior with seats and a steering wheel The dimensions and specs are as following: Built out of ~460 parts 27 x 20 x 13 cm ~ 850 grams Top speed of 7 km/h As usual there's a video showcasing the model in more detail: But just building the model and recording the video was only half the story. I also taught myself how to create the building instructions using the Studio which can be found here: https://bricksafe.com/pages/Zblj/simple-off-roader Since these are my first such instructions, they may not be ideal... So in a case of any issues, confustion, or such I also uploaded the .IO and .LXF files which can be found in the corresponding Bricksafe folder: https://bricksafe.com/pages/Zblj/simple-off-roader All in all this was a great learning experience, I'm always happy to learn a new skill and being able to create my own instructions sure is a good skill to have as a LEGO builder. To conclude; using this as a base, I wonder what kind of tweaks, improvements and crazy mods other builders will come up with!- 17 replies

-

- instructions

- buwizz

-

(and 5 more)

Tagged with:

-

[MOC] RC Telehandler

legomarat posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

After several years I am back! My latest MOC is Lego telehandler based on CAT TL642. Since it is not an exact reproduction I decided to change name and logos. Buwizz and iPad are used to control it remotely. There are four motorized functions: drive with PF L motor, boom elevation with PF L motor, fork tilt with M motor, and steering with PF servo. Front wheels are driven through a differential, and the rear axle has a simple suspension. Overall, it is maneuverable, easy to operate thanks to the proportional control of Buwizz, and very fun to play with. Please check out my flickr and https://www.flickr.com/photos/marat_andreev/ my instagram www.instagram.com/legomarat/ Interior controls are made with stickers Also I found a nice reflective sticky paper to make mirrors- 16 replies

-

- power functions

- technic

-

(and 2 more)

Tagged with:

-

[MOD] Motorized Bugatti Bolide 42151

KirTech LAB posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi everyone! I'd like to share my new motorization project. This time I've modified Bugatti 42151: BuWizz 2.0 receiver as a power source, BuWizz-motor for rear-wheel drive and PF servo-motor for steering. As usually I tried to keep the original look of the set as much as possible and it was unexpectedly difficult to place all the electronic components. The main problem is a width of the model - the inner space between doors is only seven stud wide, so it's impossible to place the receiver between the doors as it's eight stud long. So I've ended up with pretty unconventional receiver placement. You can find details and test-drive in my video: Thanks for watching :) -

1:10 Large - scale motorized 4x4 Tow truck

Zerobricks posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I don't usually post my work projects here, but every so often there is a special one that I really want to showcase more in detail. Today I want to show you one of my all-time favourite projects, which is packed both full of functionality and a very high level of detail. Before we go into the details, lets' first let's talk about the idea behind it. We (the BuWizz team) have been cooperating with Slovenian AMZS (Slovenian Automobile Association) for a while now and they are the ones who allow us to record the various speed breaking and such events on their polygon. An idea emerged for a project to design and loose replica of their existing Tow Truck which is to be used for education purposes. Here's how one of their tow truck looks like: I decided to use this specific model as an inspiration of my representation and here were the basic starting functions and features: 1:10 scale Capable of lifting and towing an actual 1:10 model like 42125 All Wheel drive Working gearbox Realistic suspension Highly detailed As with most of my projects, i first started working in LDD and this is what the first prototype looked like: I took some liberty with the shape, notably I removed the crew compartment in order to better the lift arm details. As the project progressed, so did the amount of functions, features and details until I ended up with this long list: Motorized with 11 motors Powered by 2 BuWizz 3.0 Pro bricks All wheel drive powered by 4 BuWizz motors Working gearbox with a high and low gear 3 differential locks Independent suspension in the front Solid rear axle in the back which uses 3x13 curved panels as leaf springs Working V8 engine connected to the drive motors Functioning steering wheel linked to the steering rack Motorized lift which can unfold, raise and lock onto thr wheels of the towed vehicle A motorized winch in the rear Working front LED lights Opening doors, hood and compartments Detailed engine bay with battery, air filter and washer fluid Compartments filled with details such as fuel canisters and various tools Other details include cones and fire extinguishers 3D printed braking discs in the front for show Total piece count is around 3060 parts Just over 3 kilograms 51 cm x 24 cm x 22 cm when folded excluding mirrors Capable of lifting and towing a 1:10 scale car like 42125 even up a steep hill Top speed of 10 km/h Here's an overview of the model and the basic mechanical functions: Driveline is powered by 4 BuWizz motors. The motors drive a 2 speed gearbox and a fake V8 engine: Gearbox is powered by a PU M motor and uses 2 mini linear actuators to switch between low, neutral and high gear: Each of the 3 differentials has it's own lock, actuated by a wave selector and powered by a PU M motor: Steering system is powered by a PU L motor and uses two steering racks in order to both steer the wheels and turn the steering wheel: Finally, there are several more PU M motors used to power the rear arm. The main actuators lift the whole arm and are powered by 1 PU M motor: Another PU M motor is used to unfold the lower part of the lift arm using 2 mini linear actuators: Finally another PU L motor is used to lock the wheels with two more mini linear actuators. The driveline is designed in such way that the arm can swing a bit while cornering: The lifting arm had to be designed to be as strong as possible, yet thin enough to slide under the car we want to tow. The final version was under 2 studs high and capable of lifting a 2 kilogram heavy model with ease: With all the details finalized and the parts omptimized in the LDD version, it was time to build the real deal: As mentioned above, the model is full of details that can be accessed by opening the various compartments: The rear view showing the folded tow arm and the 2 large actuators used to lift it: Few more pictures of the model next to the real deal: Of course no Technic photoshoot wouldn't be complete with the most important photo of them all, the underside: The underside was left open and exposed intentionally, so that the gearbox, the differential locks and steering system can be observed. Of course as with all the projects, this one also had some issues, the biggest being the use of 3x11 curved panels as the rear leaf springs. Originally only a single pair was used to support the weight in the rear and the additional load of a towing vehicle, but it soon proved too much for them and over time they ended up breaking. That is why for the final fix, they were doubled, to increase the stiffness and durabilty of the rear axle: Other than this, there were no other major issues with the model. The driveline has yet to skip a gear, the joints are holding (even the small CV joint used in the front left side) and the model ended up being robust enough for some really rough driving. As mentioned at the start of the topic, this is one of my best models to date, I'm really happy with the amount of sheer functionality, features and details I managed to cram in it and it will forever hold a special place in my heart. To wrap up this already long topic, here's a couple of videos of it in action: -

[MOC] Off-road truck Gaz 66[instructions available]

keymaker posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi, I would like to present my newest creation – off-road truck Gaz 66. It is my interpretation of small, old and very popular truck, which has a lot of off-road capability. Someone can ask why next similar small scale off road truck? I would say I like this type of vehicles, the scale and challenges they bring. And with every build I try to test something new, which I wasn't try before. Here the main goal was to go below standard for those wheels width of the model - 15 studs and prepare narrower axles than standard - 11 studs ones. Which I did. Gaz 66 has 13 studs width body with 9 studs (from rim to rim) front axle - stereed and driven. Thanks to that size of the body is more proportional to used wheels. And you can also use tractor tires provided with cargo for even better effect (you can see such modification in real Gaz 66 on one of polish off-road YT channel - LINK). I also tried to add as many details related to real truck as possible, in this scale, I hope there are here some fan of original Gaz 66 and they will recognise some elements I added. Below you can find video and list of features and details. Enjoy. Instructions: LINK General details scale: 1:20 dimensions LxWxH: 30x10,5x12,5cm weight: 946g Features: RC front axle steering (C+ L motor) RC 4x4 drive (C+ L motor) RC winch with place to lock the hook (C+ L motor) 4-link live axle suspension for all 4 wheels three studs ground clearance (with "KrAZ" tires) openable doors and easy access to spare tire working V8 engine with fan located in cabin, plus grill via which working engine can be watched detailed two seats cabin powered by Buwizz 3.0 but also prepared to be powered by standard C+ Hub can operate with "KrAZ" tires included in cargo Photos: LINK My Gaz 66 is powered by Buwizz 3.0, but there is no problem to use standard C+ Lego battery box: Internals of the MOC, so drivetrain connected with V8 engine, steering and the winch: -

Tamiya hot shot RC - instruction now available

msk6003 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Finally finish front bumper and fully tested. So I made box art. This is original model's box art. Without bumper, I added ARE YOU HOT plate on backside of wing. Final model spec 2 Buwizz 3.0 2 Buwizz motor with 4WD drive 1 C+ L motor for front steering Monoshock both front and rear like original model 3 speed gear ratio can choose while building(include in instruction) 4.2:1, 1.96:1, 1.4:1 Instruction link -

[MOC] Unimog U5000 Trial Truck

Teo LEGO Technic posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hey everyone! After almost a year and a half of working on it whenever I had time, my model of a Unimog U5000 truck is finally complete. It has the following functions: 4x4 Drive with 2 PF XL motors Steering with PF M motor and linear actuator Remote diff locks, front and back, using pneumatic actuators Remote 2-speed high-torque gearbox BuWizz power More photos on my BrickSafe: https://bricksafe.com/pages/Teo_LEGO_Technic/unimog-trial-truck The whole idea of this model was to build a truck that could both travel at a fairly fast speed as well as work very well offroad, which meant it needed a gearbox. It also meant it needed differential locks so that turns could be taken smoothly at high speed with diffs unlocked, and offroad terrain could be tackled better with diffs locked. The main goal of this model was to create a drive train that wouldn't allow any gear slippage or breaking even under tension in low gear. My solution for this was to use @Sariel's heavy-duty gearbox (http://sariel.pl/2011/02/2-speed-heavy-duty-linear-gearbox/), as well as the new differentials from the 43109 Top Gear car. However even those differentials can't take as much torque as I wanted to put on them, and neither can the universal joints leading to the axles. For this reason, I decided to speed up the transmission before reaching the universal joints and differentials to reduce torque, then slow it back down afterwards between the diffs and the wheels. This would cause a bit of power loss to friction due to the increased number of gears, but it would reduce the torque on the sensitive components and allow me to send more total torque to the wheels. The result is that the 2 powerful XL motors are sped up 5.01 times or 1.8 times (in high and low gear respectively) before reaching the diffs and universal joints, and then slowed down 11.67 times at the wheels. Therefore the final gear ratios in low and high gear are as follows: High gear - 2.33 : 1 Low gear - 6.5 : 1 The result is that the drivetrain is indestructible and never breaks even when run with a BuWizz on ludicrous mode and the wheels come to a standstill. The most complicated part of this build was fitting all of the functionality in the front axle - linear actuator steering placed close to the pivot to increase the range of motion, lots of gear reduction, portal axles, and a differential locking mechanism. Although the result is quite good in my opinion - thanks @Zerobricks for the custom portals - the final construction wasn't as sturdy as I would have liked, and this was the main issue with the final model. The steering has less power than I would have liked with the small actuator, and the custom portal axles bend outwards under pressure when steering over rugged terrain. Overall however I'm quite satisfied with the final result Thanks also to @functionalTechnic for the advice, and to everyone else who contributed to the WIP thread: Enjoy! - Teo- 8 replies

-

- trial truck

- unimog

-

(and 4 more)

Tagged with:

-

[MOC] 42151 Bugatti Monster Bolide

mla2 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Last few days I've been working on a motorized version of the Bugatti Bolide using the .io file @Void_S posted earlier (thanks again!). I wanted to do the motorization by adding a diff, a Buwizz 3.0 + monster motor and a PU L motor for steering, all without impacting the looks except for removing the HOG. Adding the PU L motor was pretty straight forward. It increased the existing gap that's between the dashboard and the front hood but later I found a nice solution to close this gap again. To add the monster motor and the diff I used the same design as in my 8865 New Jeep MOC. It's very strong and doesn't suffer from any gear skipping. Fitting this required some changes on the back side but none of those change the looks. Adding the Buwizz 3.0 was the hardest, it's quite big and I tried to many ways to get it to fit. In the end I found a nice way to hide it well, this did require the removal of the seats and also some minor changes to the sides: the yellow door panel had to be moved one stud outward and half a stud backward. It think this looks pretty good actually, perhaps better than the original. Additionally I had to change the two bottom new panels in front of the rear wheel with a single old panel but that's it. Using an Lego Buggy motor doesn't work, there's no space for the PF connector it requires. I don't have the set yet but I built it all using my own parts and made it so all connection points for the new panels are there again. All panels are fixed at least as well as in the original design except for the aforementioned yellow door panel which is only connected with a single pin now. Here's 2 work in progress photos: It drives really well and when it's fully built you don't really notice the motorization which is exactly what I was trying to achieve so I'm happy :) Especially the cabin is still nicely spacious. I will be able to build it with the real set parts soon, I managed to order it somewhere and it has been shipped. I did already finish the virtual model and will make free instructions available once I can test the full build and instructions. Thanks for reading and hope you like it, any feedback is welcome! Here's some renders of the model: -

[MOC] Police Interceptor

Anto posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

After a while without a new MOC (because of my studies ^^), I'm back with a new model! It was made for BuWizz. The aim was to make a model in the continuity of my cross kart. I wanted to get rid of the torque effect on the rear axle (as it was a suspended axle on my cross kart), that made the behaviour unsymmetrical in corners. So I used 2 BuWizz motors as wheel hubs instead! The rear suspension was made so the rear shock absorbers generate friction, in order to have a slow rebound. On my cross kart, the suspension was extremely reactive, but the kart was "jumping" on gravel. On this new buggy, having a slow rebound helps the wheels stick on the ground to gain adherence. However, I wasn't able to do the same thing on the front axle. Why a police buggy? I have never seen this before, I thought it could be nice. I wanted the design to be as agressive and massive as possible. I wanted the design to be close to Polaris or Can-Am, looking heavy, indestructible but fast in any situation. People had to fear seing it in their mirror. You may have seen that the main part of the bodywork was made with 2x5 panels. This was a very useful part to achieve the shapes that I wanted, and to have simple assemblies (no one uses complex building techniques). The BuWizz 3.0 has got 2 PF ports and 4 PU ports. The 2 BuWizz motors are connected to the PF ports while the PU L motor for the steering (acting as a servomotor) and the LED lights are connected to the PU ports. The performance is really great! It is absolutely impossible to use more than the half of the power into a house! And outside, the suspension works well. You can go almost everywhere without being stuck or loosing grip. I also had some crashes but nothing was broken nor fell apart! Little video: And the instructions! https://rebrickable.com/mocs/MOC-132106/Anto/police-interceptor I hope that you'll like this model, and see you soon for the next one! -

Hi, I present my newest creation – off-road truck KrAZ 255 version 2.0. This is successor of my first public MOC – KrAZ 255 to which free instruction are available here. The goal in version 2.0 was to improve basically every aspect of predecessor and to pay respect to this awesome off-road truck. And as usual, most of the features are based on truck Tayga 6455B available in game Snowrunner. This truck is also the next part of my Snowrunner series started with Chevrolet CK1500. On the video below you can check what details and functions I was able to put into this MOC and how KrAZ 255 v2.0 deals with off-road terrain and against obstacles. Extensive list of features, details and interesting facts about this creation you can find below the video. Enjoy! Instructions: LINK General details: scale: 1:23 dimensions LxWxH: 42,5x13x16,5cm weight: 1525g Features: 1. RC front axle steering (C+ L motor) positive caster (click) Ackermann geometry almost perfect pivot point (click) PF servo friendly - 180 degrees of movement for steering input 2. RC 6x6 drive (2 x C+ L motor) independent drive input for each front wheel (click) (for this idea I would like to thank @Fluwoeb and this topic, this is because of you! ) rear wheels driven by two independent inputs (one for 2 left wheels and one for 2 right wheels) (click) front wheels driven by one differential and rear wheels driven by second differential (click) both differentials coupled together to harness power of two C+ L motors both differentials coupled with lock mechanisms (click), controlled separately and manually from the cabin (click) and equipped with visual color indicator of diff lock on/off status located behind the cabin (click) power train equipped with new big CV joints - cardans and old CV joints limited in drive of the front axle and completely removed from drive of rear axles 3. RC winch with place to lock the hook (C+ L motor) 4. RC front and rear lights (Lego LEDs) 5. suspension for all 6 wheels (click) front wheels on live axle suspension with shock absorbers (click) and a big range of movement (click) rear wheels located on independently oscillating arms with rubber suppressors controlling the movement (click) rear suspension without shock absorbers - no side leaning and no bending under the load (click) 6. three studs ground clearance (click) 7. bottom of the truck armored with panels to secure crucial mechanisms and improve dealing with obstacles (click, click) 8. two hooks for connecting trailers, front and rear one, both equipped with lock/unlock mechanisms 9. openable doors, hood, tool box, first aid kit, sideboard bed with separately openable sides, each one with two locks 10. working V8 engine with fan which can be easily removed “for maintenance, repairment or for swap” located in detailed engine bay with a grill via which working engine can be watched (click) 11. detailed two seats cabin with openable and usable glove box (click) 12. working steering wheel 13. modular construction (axles, cabin, additions can be easily disconnected) 14. powered by Buwizz 3.0 but also prepared to be powered by standard C+ Hub (click) 15. prepared to be built also with PF motors and PF servo without significant changes and to be powered by Buwizz 2.0 (click) or even standard PF Battery box with IR receivers (click) 16. "disk brakes" in front (click) and rear wheels and many others small details (click, click, click) 17. equipped with many additions from the game Snowrunner, like bull guard, exterior roll cage, roof rack with fuel canisters and spare tire, double snorkel, sun protector (click) Interesting facts, designing decisions and details: driveshafts for front axle are connected in a way that the longer, more “smooth” CV joint part are connected closer to front axle, so lower to the ground, which corresponds with the idea to prepare bottom of the frame smooth and resistance to sticking out objects which can immobilize the truck (click) most of the motors are placed symmetrically at the center of the truck, which is good for weight distribution, but Buwizz unit is localized off centered, closer to the left side of vehicle. To balance that, motor from winch is placed also off centered, but closer to the right side of truck (click) all wheels can harness power from both C+ L motors, as they are coupled, but rear axles, which in general generate more load for motor, are connected closer to the right motor, that is why V8 engine is connected closer to the left motor, which is connected closer to front axle, as the front axle generates less load than rear ones (click) additionally output for V8 engine has the same speed as motor output - which is higher than rest of the drivetrain - for better visual and sound effect (click) there is a „biscuit connector” placed in rear wall of the cabin to increase ways of location and connection and types of power source which can be used to power up the truck (click) to avoid widening the whole truck, only hinges for sides of sideboard bed are located outside of the sideboard bed to allow opening sides to vertical position, which makes loading the cargo easier (click) positive caster present in front axle has (apart from being next feature adapted from real cars, apart from dealing with not very high tolerance of Lego parts, which causes negative caster and apart from being the force which steers front wheels strait when driving forward) a function of forcing front wheels to stay on axles when driving forward (I think this is the answer you were looking for @AutoBacon in this post ) and many more details you will discover, if you decide to build my truck I would also like to thank @nico71 for his great video series related to Western Star 6900 Twinsteer. It helped me to prepare more realistic grill, hood, roof elements and I believe overall better body of the KrAZ than in my first version of this truck. Thank you! Attention! Two C+ L motors with decreased speed 3 times, so with torque increased 3 times, generate a lot of force which needs to be handled by rather advanced drivetrain. That is why there is a risk for 12T gears to skip or even be destroyed if wheels come across too much resistance due to very rough terrain. Please keep this in mind and happy off-roading! Photos: (click) Here you can see the original KrAZ-255 (1211 parts, 991 grams), the new KrAZ-255 v2.0 in standard configuration (1632 parts, 1220 grams) and the fully equipped and ready for everything version of KrAZ-255 v2.0 (2091 parts, 1525 grams): Internals of the MOC, so drivetrain with differentials and diff locks connected with V8 engine, steering with working steering wheel and the winch I hope you like it, if you have some comments or question, please ask. I will happy to answer.

-

Technic ans Scale models at Bricking Bavaria 2022

functionalTechnic posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi everyone Last weekend the Bricking Bavaria 2022 took place in Fürth, Germany. LEGO builders from around Europe travelled to Fürth to show their models. This year large cranes, lang heavy load transporters and even a technic locomotive in scale 1:17 were shown. It was really inspiring to meet other builders and learn about their building techniques, concepts and how their model work. For all people who had not the possibility to come to BB22 I cut a video with as many models in action as possible.- 20 replies

-

- lego

- lego technic

- (and 14 more)

-

Universal 4x4 off-roader

Zerobricks posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

This model (and it's prototypes) are a result of the following topics: Basically the idea behind this project is to make an offroader capable of driving on all kinds of terrain with a simillar perofrmance as the Wildcat 6x6 but having a lower weight So, why would I want to reduce the weight? While the wildcat 6x6 works great most of the time, it's high weight of 2,5-3 kg has some drawbacks: The model requires a lot of expensive electronics (12 BuWizz motors, 6 BuWizz 3.0 bricks) High part count (1869 pieces) Tendecy of front wheels falling off at hard landings High wear and tear of the individual components, which lead to premature failure - planetary hubs, CV joints And lastly high wear and tear of the handler due to it's heavy weight Of course decreasing the weight also means decreasing the power to weight ratio, since there will always be components which are needed regardless of the number od drive motors like wheels, hubs, steering system, suspension and frame. The first protoype, which I simply call Light 4x4 used only 2 BuWizz motors coupled to a 2 speed gearbox: While the model worked good in low gear, the high gear proved much trickier. The single gearbox put a lof of strain on the drive axle in high gear, causing it to melt, even with lubrication. Another issue was the high load of the motors in high gear, resulting in them overheating, while the motor could not even remotely apporach the 15 km/h top speed of the Wildcat 6x6. But not all was bad, I really liked the free-moving front suspension which acts like a suspended pendular axle, while having a much lower unspring weight. While I could make the rear suspension act like a pendular axle instead off front, i decided agaisnt it, since most of the weight is shifted back when crawling and I wanted to keep the rear stable. With that knowledge, I went back to the drawing board and decided to up the power for the next version... Medium 4x4 prototype: This version used 4 BuWizz motors coupled in a manner simillar to my 1:10 Acura NSX which negates the sideways load on the output axle of the gearbox. As you can see, this version was quite bigger and it used the reinforced differentials. The increased power drastically improved the performance, the top speed and overall power being simillar to the Wildcat 6x6. BUT the model had a few problems, main being the exposed gearbox which would get clogged and jam while driving outside. This version was aslo wider compared to the first prototype. Medium version prototype 2: This is another concept where the entire front axle is designed to pivot, but I ultimately decided to go agaisnt it due to the higher center of gravity and higher unspring mass. The final, universal 4x4 model: I have built and tested the model, but have yet to make any media, that's why I'm using LDD photos for now. I had to way to make the model more ingress resistant and narrower. This is where I came up with the idea of using the new, reinforced differentials as 28 tooth clutch gears for the high gear of the gearbox: This way the gearbox's output axle was moved a stud lower, allowing me to cover the bottom of the model with panels which prevent the dirt from getting into the gearbox without sacrificing ground clearance: The model inherited the front axle from the prototypes which acts like a free pendular axle. This keeps the weight even on both side of the suspension sosimple open differentials sufficed without a need for lockers. The gear ratios are a bit of a compromise comapred to the Wildcat 6x6, with low gear being 0,89x the ratio and high gear being 0,83x the ratio. Even with these differences, the model still reaches a very simillar speed in high gear, probably due to lower friction losses and lower rolling resistance. All in all I think this is a worthy successur to the Wildcat 6x6, even though it may not be as flashy, massive or functional (no skid steering). Final part count is 774 pieces which is 41% od the Wildcat 6x6 and the weight has been reduced to around 1,4 kg - around half of the Wildcat 6x6. I will be creating a proper in-depth video about the finished models and the protoypes, so I suggest you to watch this space for more upcoming details. -

Wilde Beast 4x4 Pickup [MOC]

Daniel-99 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hello everyone! I am glad to introduce you my new Lego MOC. It is called "Wilde Beast" and it is a 1:10 scale 4-wheel drive pickup truck. Technical characteristics 1:10 scale, 1.630 kg of total weight All wheel drive with 4 x Buwizz motors powering each wheel separately 2 x Geek servo for steering 3S Li-Po for power RC radio + Wixy units for control Full independent suspension with customizable hardness Custom wheel hubs with metal bearings RC wheels 90 mm (12 mm hexes) Metal U-joints in the transmission Robust 3D-printed steering bones Positive caster angle on all wheels Back to the beginning The main Idea behind the build was inspired by real e-cars. This cars has no gearbox, and each wheel gets connected to an e-motor independently. I tried to replicate this principle with Lego bricks and some custom parts. Bodywork This car has is a 1:10 scale pick-up truck body, Though it is a bit too short for a normal pickup. The body was made to be light and it is build on the chassis with a half-stud off-set in order to make the wheels seating symmetrically in wheel arches. (It was an obligatory decision due to the positive caster angle). There are many things that can be improved in the bodywork, but the current one perfectly satisfy my needs: it is light but make the car somewhat recognizable as a car. Hope to find white fenders to the front wheels some time! All the driving elements are located in the lower 5 studs of the car, so it is very stable. Suspension Wilde Beast has a full independent suspension with positive caster, which is very unusual for pickups. Moreover it was made to be customizable for different purposes. 9L shocks connected to the lower bones of the suspension play main role. At the same time upper bones of the suspension has their own set of shocks which can be customizable! Custom wheel hubs provide a natural King-Pin Inclination. Transmission "A good transmission - is no transmission"... This was my main philosophy for this car. The car has 4x Buwizz motors for propulsion, each motor is connected to one wheel of the car via half-axle (which uses metal U-joints). "Gear Ratio": Slow output of Buwizz motor -> 95 mm wheel. Such solution has its own positive and negative aspects. Positive: extremely low friction stiffness fast cornering (e-differentials) High maximal speed (over 13 km/h) Negative: Too big stress on motors (a smaller wheels would work well) Car does not go straight due to the difference in motors Let me explain the last "problem" in more details. The motors used in the car are "the" same from the view-point of a lego builder. Though they are "different" from the physical view point: each motor has individual characteristics, such as resistance, max power, max rotation speed and so on... This difference can not be seen in slow models (with max speed under 7 km/h) but they became critical at speeds over 10 km/h. As the result, car is always turning to one side and the driver need to correct the trajectory with a steering. There are only two ways to fix this problem: either to make a mechanical balancing via differentials, or to test each motor separately, and make individual power curve to it. A steering system with build-in hygroscope might also help. Controls The car is controlled via RC radio. The whole system is very similar to RC car setup. 3S Li-Po is used for power, it powers controllers for driving motors (called Wixy). The controllers provide the power to Buwizz motors by a signal of receiver. The model is steered with 2 x GeekSevo, though one would be enough here. To see a detailed description of the system, see here: Conclusion The Wilde Beast was a great research project for me. I tried to replicate a real e-car layout and my goal was achieved. Car is very fun to drive, but the driver needs to pay a careful attention to the road. The main problem of the car is the lack of the e-brains which would allow to calibrate the driving motors... P.S. I will definitely make another car with same chassis on smaller wheels to reduce the load on motors. -

12 legged Lego Walker inspired by Strandbeest

shroomzofdoom posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

The specs: - 12 legged walker - Driven by 2 Lego Technic Large angular motors - Powered by Buwizz 3.0 - 1 Technic L motor powers the deployable spinning Lego buzzsaw - 1 Technic S angular motor to power the Lego arrow shooter Sorry Lego purists, but I had to use some non-Lego parts in this design: - 4.7mm aluminum tubes front run the width of the robot providing lightweight articulation of the legs in lieu of plastic axles - Stainless steels axles are used throughout the driveshaft due to the inherent limitations of backlash and breakage caused by the Lego plastic axles - Small nuts are threaded onto the upper leg pivots to maintain the connection as Lego bushes simply cannot retain the axles given the duty cycles. -

1:10 Scale Motorized Acura/Honda NSX Supercar

Zerobricks posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

After building the 1:8 scale Spano GTA, I wanted to make something more compact, yet even more functional for the BuWizz camp 2021, which got postopned to 2022. The rules behind this model stated to build a 1:10 scale representation of a real existing car, which has to have a working gearbox, fake engine and working steering wheel. After researching different types of super and hypercars, I chose the Acura/Honda NSX since it had several good pros compared to the more famous brands like Ferrari or Lamborghini: The real car has a smaller profile, which means a lower weight It uses a hybrid AWD system, which would come in handy for the LEGO model for accelerating and braking on all wheels Engine powering is a V6, which doesn't take as much space as the typical V8, V10 or even V12 Since it's a less known supercar, my LEGO version could be the first one in such scale I used a simillar technique as with Spano GTA where I imported the 3D model into the Lego Digital Designer and used it as a 3D reference. Using this technique I ended up with a really close representation, and it really shows: As you can see in the gif above, not only does the model look very good, it's also full of functionality: 4x BuWizz motors for driving All wheel drive 2 Speed gearbox Working fake V6 coupled directly to the drive motors Working steering wheel 2x BuWizz 3.0 for control Double wishbone suspension on all wheels Dimensions and weight ended up as following: Length: 45 cm Width: 20 cm (without mirrors) Height: 12.5 cm Weight: cca 1,5 kg Here is how the model's underside looks like, drive motors are driving two independent gearboxes in order to evenly spread the mechanical load. This kind of a setup also cancels out any side forces on the central drive axle, thereby reducing friction and wear: In order to cram all the powertrain components in the rear the drive motors are placed in a V shape. This way there is just enough space between them for a functional V6 engine and a PU medium motor which switches the gearbox: Thanks to the compact powerline and driveline, the interrior is very spacious and both seats are almost 1:8 scale sized, measuring 6 studs wide. There are even stoppers and interrior details on the doors themselves: ž The end performance of the model is higher than what I expected, there is enough torque to freespin all 4 wheels, jump over ramps and top speed in high gear is almost 20 km/h! You can see how well it performs the video: To conclude, this is my first 1:10 scale supercar which also ended up extremely compact, functional, robust and good looking. I also think a 1:10 scale may be beneficial when it comes to reliability and robustness, since models tend to weight half the weight of their 1:8 counterparts while still incorporating a simillar level of functionality and details. Having said that, this will not be my last 1:10 supercar and I think for the next one I will ditch the gearbox and simply drive the wheels directly from the motors without any weak differentials. -

Here's a model I actually completed a year ago in order to be unveiled in time for the BuWizz picnic back in 2021, but we all know how things went... Anyway since the picnic did happen last weekend, I decided to unveil my most powerful offroader. The basic design is based on the Wildcat 4x4, but this version adds more power, a 2 speed gearbox and a third axle to the formula. As with the older version, each axle has independent suspension, plus the entire axle can pivot or swing, effectively giving this model double suspension setup. Indepedent suspension is great at absorbing small bumps when driving quickly, while the axles pivot along the terrain when crawling. The driveline was quite a challenge. In order to transmit the power from 12 motors to the wheels, each wheel ended up having it's own dedicated 2 speed-gearbox. The final driveline is extremely compact and efficient, with only 3 gears engaged at any given time. There are also no differentials or perpendicular drives, so nothing that can break or skip. Each gearbox is actuated by a PU M motor using worm gears, which prevent any unwanted skipping out of the gear. This way each wheel is powered by 2 BuWizz motors via a dedicated gearbox: The following gif shows how the front axle is designed along with the whole model: Here you can wee, how the front axle tilts in order to adjust to the terrain: The rear axles are made in the same way as the front axles, minus the steering. Rear axles are also designed to work in tandem, when one goes up, the other goes down. When one tilts left, the other tilts right. This way the rear suspension is extremely flexible: And finally here are some specs of this beast: Length: 52 cm Width: 26 cm Height: 20 cm Weight: 2,5 kg Top speed: 15 km/h (rounded up) To complete the presentation, here's a video of the model in action, a big thanks out to @braker23, @Sariel and @kbalage for the footage. Final thoughts... this is my most potent offroader to date. The sheer amount of power, torque and speed is hard to wrap your mind around for a model made entirely of small plastic pieces. Having said that, I think there are still few areas to improve: Tendency of the front wheels to fall off at hard bumps - A lighter version would help to reduce stress on the hubs and wheels. Could use a higher steering angle - Would have to find a way to integrate steering racks inside the transaxles. Protection againt depbees and dirt entering the drivelines - Something that would also not reduce the ground clearance, tiles might work.

-

PHANTOM Baja Truck [MOC]

Daniel-99 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hello everyone. This is a story of my mid-scale RC baja truck called “Phantom”. The beginning. I always had a strong desire to go fast. For that reason I made my Red Roadster powered by Buwizz motors (See my Profile for dedicated post). But this sport car has one significant disadvantage - it requires a very smooth road! So I decided to build a trophy truck. I learned a lot about trophy trucks made with Lego. Best of them had 2 Buggy motors for propulsion with a direct connection to the rear wheels. So I decided to build myself a similar setup. First trophy truck I designed in big scale (~1:10) but Buwizz motors were struggling with a load from big wheels (and that is not a problem of motors, but a problem of construction). So I made a portal reduction and the problem was solved. After that I build an ultimate dune Buggy “Dragonfly” with independent suspension driven by couple of Buwizz motors. The result was great, Buwizz motors allowed to drive it very fast on 85 mm wheels. So I decided to build a trophy truck with them. Such wheel size is the smallest one which could be used outdoors. Smaller wheels does not provide enough of ground clearance to go full speed on bumpy terrain. Photos. Front axle. I started the build with the front suspension. A technical task was the following: - to use big Lego wheel hubs - double steering rack - positive caster angle - ridged suspension arms I took many ideas from the front suspension of my Dune buggy and tried to make it smaller. Dune buggy used 9,5 L shocks so I decided to change them to 7 L shocks. Also I was able to avoid ball connections, since they struggle a lot at bumpy roads. Here is the result. The steering motors should get connected to the vertical black axe (on the first picture). The key idea was to place steering arms horizontally and in a slight diagonal way. Such placement caused some friction in the steering system, but from the other hand it reduced the wobbling to ZERO! Also there is a 3 studs distance from the connection of steering arms to the wheel hub and the pivot point of the hub (see picture 2). It reduces the maximal steering angle, but strengthen the steering system and make the control smoother! Rear axle. A technical task was the following: - direct mounting of Buwizz motors to the rear axle - Long suspension arms and long travel - Suspension with progressive hardness I decided to make it simple without any articulation, though there was some provided by bending of plastic parts. There are two sets of springs used. Small vibrations of the rear axle get absorbed by a soft 9.5 springs, while hard bumps compress the rear axle stronger, so the set of 7 L springs does their job. Finally, there is a couple of Lego rubber elements which play a role of fenders. So there are three stages of compression. First stage. Soft settings. Second stage. Hard settings. Third stage. Rear axle touches the frame. Frame of the car and bodywork. A technical task was the following: - two layers of frame - use the roof of the car as structural element - minimalistic bodywork The space frame of the car consist of two layers. Roof of the car tighten the upper layer in order to bear the load from the rear springs. The middle compartment is dedicated to power sources. The "new" cross-beams (15L and 11L) were very helped a lot. The bodywork is made with several panels which can be easily detached for servicing the electronics. Electronics. On photos above you can see a custom Lego-compatible RC unit equipped with two high power cells 18650. It provides more power comparing to Buwizz 2.0, but it is not enough for two Buwizz motors. It get overheated quite fast (5-10 mins). One may ask me, why I use it. Actually, the first version of the Phantom was powered by two Buwizz 3.0 units, which provided a plenty of power to the car. But I managed to drown the car at first outdoor driving test! So I bought replacement for them since there was no possibility to purchase new Buwizz units in Russia. Here is the video of an accident: This month I bought a different Lego-compatible RC electronics from a Russian AFOL, it is called "Wixy". It plays a role of the controller for RC motors and allows to power my cars with 3S Lipos! WIth 3S Lipo I forgot about lack of power and was able to ride the Phantom for miles and miles... Conclusion. The car Is made for outdoor driving. It has a decent speed and a good control. Though there are several weak places of Phantom which can not be fixed with plastic Lego parts. The dust is very annoying, especially on county roads! It fills all holes of the car, most importantly plastic wheel hubs. I destroyed all the wheel hubs I own and there is no way of fixing the problem... Also the car has slight problems with ground clearance - it is acceptable for city roads but too small for stony surfaces. Finally, the Truck can not go trough the tall grass with such small wheels and RWD. -

[8081 MOD/MOC] MM //COMMANDO// - Winch is ready!

johnnym posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Some might still remember this offroader I started sometime ago in 2019 and showed earlier versions in the 8081 mods thread a while ago. Well, I finally "finished" it now and created digital models for it. I call it the COMMANDO and it is "sold" by MM (Mars Motors). People that follow my Turbo Racers series and my series of 42093 scale cars with swappable engines should already know MM. To show its capabilities I made a trip to a special location and examined what it can do there. Have a look into the video to see what it possible: The configuration in this video has all axles locked and uses the drivetrain variation #2 (see below). The COMMANDO started as the glorious 8081 A model and went through lots of modifications - especially to the front and rear axles and also to the outer hull - on the way to the final result. I created three versions so far: with 1 x PF AA battery box with 2 x PF AAA battery boxes with BuWizz 2.0 ...from which the BuWizz one was used during the video and also most of the time I drove it so far. Here are a few more detailed pictures showing it in that terrain: Here are two pictures showing the chassis construction (click to magnify): ...and here are the three drivetrain variations that can be used (click to magnify) More variations are possible and the gearing can be changed with relative ease, as the motors are not an integral part of the construction: #1 is used for the PF versions and #2 is used for the BuWizz version. #3 can be used to examine the effects of open differentials in offroad situations. The COMMANDO can use various tyres and clearance should be good enough for all of them: 45982 81.6 x 38 R Balloon tyres 18450 81.6 x 44 R (Tumbler) tyres 69912 81 x 35 Tractor (Zetros) tyres I have also already designed a few addons that will be released at a later time - need to create the digital models first - and I have even more ideas for it. So far I have available: front winch rear PTO exploration gear tracks So stay tuned for additions. I hope you like the COMMANDO and I hope it is a worthy successor to the 8081 A model. If you're interested, the - free of charge - digital models (Studio files with detailed steps and submodels) and more pictures are available on Rebrickable: https://rebrickable.com/mocs/MOC-111591/johnnym/mm-commando/ -

[MOC] Blue Mamba fast off-roader

Daniel-99 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hey, Eurobricks! In this post I want to tell you about one of my latest MOCs, called Blue Mamba. It was made for outdoor King of the Hammers competition. Unlikely I was not able to participate in the competition this year, but I am not disappointed because it is very fun to drive this car. Main features 4-wheel drive In-axe motors (one PF L-motor for each wheel) 2 x Buwizz 3.0 units for power RC tires 97 mm Bodywork The race vehicles used at the King of the Hammers are known as Ultra 4 vehicles. This Ultra4 class is unlimited 4400, and every vehicle is custom fabricated by each team. Most of the vehicle made with metal tubular frame and plastic body panels. I tried to replicate the bodywork to match the real prototypes. Black pieces imitate a tubular frame of the car. Side panels and the hood are the structural elements of the chassis. The total weight of the car is about 1,280 grams. Half of the weight (4x PF L-motors) is located in axes, this is not good for the dynamics of the car at big speeds, but helps a lot in trial. Steering motor and Buwizz units are located in the cockpit. It is possible to lower them, so there is a reason to revisit the chassis once again. Suspension The rial race combines desert racing and rock crawling. So the Lego version of the race combines high-speed and trial sections. For good performance in trial Blue Mamba has a free articulation of a rear axe. The string are placed on the middle link, so rear axe can suspend jumps. Front axe has a limited articulation for a good control at high speed. Drivetrian Ultra4 vehicles has both powerful engine and the gearbox which allows to drive fast on straight lines and slow on rock-crawling segments. But Lego gearboxes has a significant disadvantage - a huge loss of torque. So I decide to place the motors in axes. This gives nearly zero losses, but has it`s own disadvantage: an extremal load on the CV joints which connects front motors to the wheel hubs. There is no way to deal with in without widening the wheel base and adding the portal reduction.. I hope some day Lego will make a new hubs that connects to new CV joints (without planetary reduction). In-axe motor placement provides some restrictions to the size of axes. I tried to maximize the ground clearance. Big wheels partially solve the problem. The resulting ground clearance in not big as one the cars with portal hubs has, but it is comparable to the ground clearance of cars with front independent suspension (there were several competitors with such configuration). Also it is worth noting that front and rear axes does not stick out from the side profile of the wheels, so Blue Mamba has great approach and decent angles. Control and Power The car is powered by two Buwizz 3.0 units. Powerful lego cars usually have a big problem. They can not go on a full speed for a continuous time since the driving motors consume a lot of power. I build many cars powered Buwizz 3.0 units. And I noticed that 2 Buwizz motors or 4 PF L-motors consume more power then the battery can give (in continuous drive). A good example of a car with 4 L-motors and 1 Buwizz unit is my Jeep Wrangler. To deal this problem, I places two units in the Blue Mamba. This doubles the travel range of the car and allows to drive Blue Mamba on full speed during the race. But multiple tests show that 1 Buwizz unit is enough for this car, since there are no losses in the transmission (in the first video car is powered by a single Buwizz unit). For steering a C+ L-motor is used. It is placed in a cockpit in between Buwizz units. Small scrab-radius, positive caster angle and proportional steering provide a good control of a car. Summary The competition has passed, and I there is a video on youtube: This allows me to compare my car with the other competitor cars. I would not win the race but perform good. I will look for the next King of the Hammers competition and prepare Blue Mamba to it. The following changes will be made: Buwizz units will be replaced with RC electrics The cockpit will be lowered for few studs The wheel base will be lengthened for 4-6 studs (to prevent the car from flips at high stairs in trial) I made a 3D model of Blue Mamba, but I have no motivation for making PDF instructions since Rebrickable does not work for me nowadays... Hope everything will be changed soon! Now we can only wait and play Lego! -

[MOC] Dragonfly dune buggy

Daniel-99 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

DRAGONFLY Dune Buggy Hello everyone! For a very long time I had a dream to build a dune buggy, and finally, my dream come true! The main goal was to use a C+ electrics instead of Buwizz unit. Of course, I am not the first who attempted to build a buggy. I take an inspiration in Madoca`s Blue Lightning buggy. Technical specifications: - Light and ridged tubular bodywork - electrics form 42099 set (controlled with C+ app for 42099) - Long-travel independent suspension - positive caster angle on the front wheels - Long wheel for stability on the straigt lines - Double steering rack and steering arms reduce wobbling of the steering system - understeering feature (rear wheels get more grip) - RC tires 90 mm Buggy performed well, comparing to the 42124 set. It appears to be a car that is very comfortable to play with. The speed of the buggy allows you to walk with your normal speed in the park driving it at the same time! Here is a small video of my first tests: As I said, the main goal of this project was to use C+ electrics. But after that I decided to boost it with buggy motors! The overview of the car does not change much. Rear wheels get a positive caster angle, and wheel size was reduced from 90 mm to 85 mm (for reducing speed and increasing torque). Here is a short video with Buwizz-powered Dragonfly. I will definitely make another video about this car then the summer comes.