-

Posts

97 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Everything posted by michaelgale

-

Fx Bricks (Michael Gale) announces Fx Track system

michaelgale replied to HoMa's topic in LEGO Train Tech

Regarding the switch radius, I'll repeat my explanation from the flickr post here: Technically, the diverging route of this switch is not a perfect segment of a R104 circle. However it is very very close. In all likelihood, given the wide tolerances of Lego train track, you would be able to form a 90 deg turnout from the diverging route with 6x additional R104 curve tracks. There are a few reasons why the switch cannot be made with a diverging route as a plain R104 curve segment: The switches need to form a perfect crossover at 16-stud parallel centreline with the crossover point perfectly aligned to the Lego system 8 mm grid. The diverging route centreline must be exactly 8 studs laterally offset from the straight route. The switches should be able to stack into a repeating yard ladder configuration with each siding aligned to 16-stud centres The diverging route of the switch is not a fixed radius curve. Rather, it is a spline curve computed as an optimal "transition" curve, i.e. a progressive radius to match constraints at each end. This is how real railway switches are designed as well. As it turns out, the diverging route is tantalizing close to a R104 curve, but not enough that we would label the product as a "R104 switch". If you look at how real railway (and some model train) switches are described, they rarely use "radius" in the terminology. Often they will use other more relevant attributes such as the length of switch or the angle of crossing frog/vee. We chose the nomenclature of P40x since it is short and sweet and concisely descriptive of what it really is (and is not). -

Fx Bricks (Michael Gale) announces Fx Track system

michaelgale replied to HoMa's topic in LEGO Train Tech

Good detective work guys! I can confirm the open studs on the tie/sleeper in the middle of the switch is to allow for molding features on the bottom to mount a protective cover. The open studs between the check rails are to allow for 1x3 tiles to be centre-mounted for decoration/ballasting. The reference to 36 parts per switch includes items such as screws, and metal tabs used in multiple quantity. In actual fact, each switch uses 18 unique parts in all. Furthermore, 14 out of the 18 parts are shared between the left and right switch for efficiency. My comment about being expensive was intended to reflect how expensive it is to Fx Bricks to manufacture not necessarily to the customer. Having said that, I would rather set expectations higher rather than lower for retail price since this is a complex and precision engineered product. We aim to make products at a level of quality similar to brands such as Fleischmann, Kato, Brawa, etc. -

Fx Bricks (Michael Gale) announces Fx Track system

michaelgale replied to HoMa's topic in LEGO Train Tech

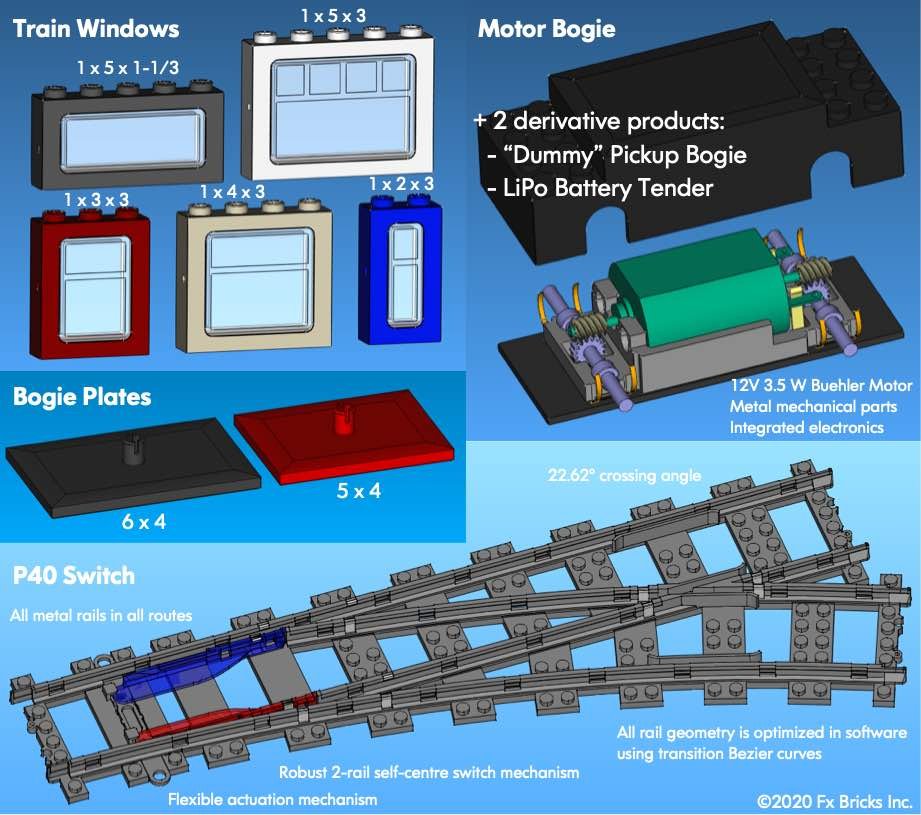

Happy New Year to All! I am glad to hear we are still stimulating discussion in the community! Apologies for the lack of updates on our site and other platforms. Rest assured, our silence is totally due to how busy we are developing our new product system and the enormous amount of work ahead. Here is a summary of our status and goals for this year: 1. Fx Bricks now has teams in both Canada and Hong Kong. The Canadian team is responsible for engineering and design and the Hong Kong team is directly connected to our manufacturing partners in China and manage production and distribution. 2. We have 2x manufacturing partners in China: i) a specialist model train manufacturer in Shenzhen and ii) a plastics manufacturer in Shanghai. 3. We are about to commit to full production for the S8, S32 straight track elements and R72, R88 curve track elements. The R56, R64, R104, S16 will be next in the pipeline. We have given pre-production samples of the S32, S8, R72 and R88 elements to Lego train fans at Brickworld Chicago, Skærbæk Denmark, and STEAM UK. We have received much valuable and useful feedback from our "fan testers" and have incorporated many suggestions into the product. 4. We hope to officially release at Brickworld Chicago 2020. We hope to have at least 3x straight track and 5x curve track elements available at launch. We will have a full demo layout showcasing our track products at Brickworld. 5. PFx Brick: We have received 1000x new assembled electronic circuit boards and are waiting for new plastic injection molded cases. We hope to have new stock in the store soon! 6. We are still working out how to perform global distribution, in particular regional distribution for our customers in the USA and the EU. 7. We have a great deal of product development in the pipeline--including items which we haven't been public about! We don't like to "hype" our development too much, but since it is the new year and a new decade, here is a teaser of what is coming... -

EMD E9A - Canadian National 101 aka Illinois Central Business Train

michaelgale replied to pirzyk's topic in LEGO Train Tech

Slick looking locomotives! Glad to see the PFx Brick put to good use and hope it's working well for you. The EMD 2-stroke prime mover would be a good sound profile to add to our small library of PFx Brick profiles. When we get some time, we plan to add more pre-configured train locomotive (steam & diesel) sound profiles giving you folks prototypical sounds to match your models. In the meantime, you can at least choose from our horn, bell and other sounds to enrich operation. Adding sound to LEGO trains is seriously fun! -

PFx Bricks

michaelgale replied to WvG_853's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

@Lasse: Awesome! Glad you got your PFx Bricks ok before your move. We look forward to seeing your PFx-powered vehicles! -

PFx Bricks

michaelgale replied to WvG_853's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Michael from Fx Bricks: We'll post to this thread when the store reopens. Sorry we had to temporarily close it--we just had to get on top of our growing backlog and give ourselves some more breathing room! Also, we've had to order more parts for production to meet the increase in demand. Stay tuned! -

PFx Bricks

michaelgale replied to WvG_853's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Wow! That's awesome! Thanks Sariel! Like I said previously, his review and evaluation of the PFx Brick was thorough, careful, and very detailed. He gave us amazing feedback which has been very helpful as we take the PFx Brick forward (hopefully to production!) :) -

PFx Bricks

michaelgale replied to WvG_853's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Jason and I have received some great feedback from Sariel personally. He certainly took the time to carefully evaluate its capabilities and made some astute observations. Obviously, we would appreciate any public feedback and engagement from Sariel to the fan community. However, we have not obliged him to do so and it is his decision to offer any endorsement. We hope that we can count on our fellow builder community to support our campaign so that we can offer the PFx Brick to builders everywhere! -

PFx Bricks

michaelgale replied to WvG_853's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

We're approaching the last week of the campaign and still have a lot of ground to cover before the finish line. We're still confident that we can get there since many folks have told us that they're going to back the PFx Brick or have only just heard about it. Anything you can do to get the word out to help support our campaign will be hugely appreciated. Hundreds of backers have already shown their generous support for the PFx Brick and are excited and hopeful to be able to get one! We really believe the PFx Brick can offer so much value in one small brick package! It combines: advanced motor control multi-channel lighting effects sound effects processor multiple interfaces: USB, IR, and Bluetooth all in a 5x4 stud brick! We hope it will form the basis of broader range of compatible products such as: A PFx Lite - low cost light effects only controller A PFx Sonic - low cost sounds effects only controller A PFx Pro - 4x channel motor controller + lighting + sound and much more! Please check out the Kickstarter campaign page at: https://www.kickstarter.com/projects/fxbricks/pfx-brick and our website at: http://www.fxbricks.com We are really hoping our fellow LEGO® fan community can help make the PFx Brick a reality for everyone! Thank you, Michael Gale and Jason Allemann (Fx Bricks) -

Thanks for posting the reminder about the Kickstarter! We're approaching the last week of the campaign and still have a lot of ground to cover before the finish line. We're still confident that we can get there since many folks have told us that they're going to back the PFx Brick or have only just heard about it. Anything you can do to get the word out to help support our campaign will be hugely appreciated. Hundreds of backers have already shown their generous support for the PFx Brick and are excited and hopeful to be able to get one! We really believe the PFx Brick can offer so much value in one small brick package! It combines: advanced motor control multi-channel lighting effects sound effects processor multiple interfaces: USB, IR, and Bluetooth all in a 5x4 stud brick! We hope it will form the basis of broader range of compatible products such as: A PFx Lite - low cost light effects only controller A PFx Sonic - low cost sounds effects only controller A PFx Pro - 4x channel motor controller + lighting + sound and much more! Please check out the Kickstarter campaign page at: https://www.kickstarter.com/projects/fxbricks/pfx-brick We hope we can count on the LEGO® fan community to help make the PFx Brick a reality for everyone! Thank you, Michael Gale & Jason Allemann

-

PFx Bricks

michaelgale replied to WvG_853's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

We've received so much feedback about omitting Bluetooth and we really misjudged how important it was to many builders. Luckily we were working on it. We reviewed the design and decided that we would commit to offering Bluetooth in addition to IR by default. The value proposition of the PFx Brick is pretty attractive if you consider that a single device offers 2x powerful motor channels, 8x channel lighting controller, sound effects processor, and remote control via IR, USB, and Bluetooth. In any case, all we can do is offer the PFx Brick to the market. Whether or not builders want the PFx Brick remains to be seen. We love the PFx Brick and really want it to succeed--but our passion for the project is not enough to decide the outcome. Ultimately, its up to everyone else. Any feedback and/or questions welcome here or direct to the KS page comments feed. Michael Gale (fxbricks.com) -

The price point of $75-100 per switch is totally in line with what O-gauge and G-scale switches retail for from manufacturers such as Peco, LGB, Piko, etc. And as you say, you need a custom curve to form a return parallel track which I would suggest should come standard in the pack.

-

Absolutely fantastic! Thanks for all of your hard work on the design. Many of us look forward to it being available!

-

I'm glad someone referred me to this topic--I certainly would like to offer some thoughts on a publication aimed at our niche hobby. Firstly, my sincerest gratitude to the entire team who contributed to Railbricks. It was a very high quality and inspiring publication to both experts and novices alike. In a way, it was *too* good--it set the bar so high that inevitably it burned out the valuable volunteer contributions that made it exist. I can only imagine how many hours were graciously contributed at the expense of other life obligations--such is the labour of love. I must admit that I somewhat cautious about the prospect of another Railbricks-type publication. Our hobby niche is quite narrow, isn't very big, and doesn't have the relatively buoyant commercial basis that the rest of the scale model train hobby enjoys. Whether you live in the USA, UK, Germany, Japan, etc., and you will find at least one or more model train publications aimed at enthusiasts in their respective regions. Publications which have broad advertising from a variety of vendors of model train products. Enough advertising revenue to pay for a dedicated editorial staff and print magazine distribution. Our hobby could never achieve that level of support commercially. There is effectively one primary vendor (i.e. The Lego Group) and a collection of small (but extremely valuable!) cottage industries making alternative elements such as track, wheels, etc. TLG will likely not choose to advertise in a Railbricks-type publication (because they don't need to) and the smaller companies can likely not afford to buy advertising with a perceived return on sales. In contrast, a publication such as Model Railroader addresses many different scales and therefore many different vendors such as Atlas, Bachmann, Rapido, Kato, etc. Even publications such as MR complain of declining advertising revenue based on a shrinking reader base. And, we can only lament the fall of so many other publications from the past, e.g. Model Railway Constructor in the UK, due to a progressively shrinking reader base. Therefore, I am not confident a funding model based on advertising will work. What about subscriptions? Well, it all depends on how much we are all willing to contribute? Also, it will only satisfy those of us who want the publication in the first place. What about new-comers to the hobby? Would they be willing to commit to a subscription right away without first seeing what the hobby has to offer? Unfortunately, there is a quite a psychological barrier between free and any dollar amount. Also, if you charge folks for a publication, it better offer substantial content with high quality. There will be a perceived expectation of quality if you charge for it. Whereas a free publication is not obliged to meet any particular standard and doesn't expose its editors to the inevitable judgements and criticisms that surely will happen. Assuming a workable "business model" can be established for a Railbricks publication, what should it offer? I have read many 1000's of model train magazines over the years. The one factor that draws me personally (and others I'm sure) is the aspirational aspect of the content. The content should inspire you. It should should motivate you to improve your skills, your ambitions, etc. To do this, it must showcase the very best of what the hobby has to offer. The argument that this will intimidate novices and put them off just doesn't match up to what sports psychologists have long known. Athletes only aspire to improve their game when they are faced with playing those who are much better than they are. My skill in chess only improved by being beaten repeatably by a master! Showcasing inspirational models and layouts gives us a sense of collective achievement--that we are able to push this hobby into the same realm of any other scale model train standard. In doing so, we can share our techniques, methods, best practices, and give others the inspiration and confidence that they can do it too. Lastly, I would offer a few suggestions to any team willing to make this happen: 1) Make the publication no more frequent than every quarter. Even four issues per year is a lot of work. 2) Make sure you have a committed editorial board of at least 3-5 folks to share the work of content planning, strategic direction, etc. 3) Have at least one dedicated content editor and one dedicated graphic designer/producer. Maintaining the continuity of quality and consistency requires that both the content and its visual design have dedicated attention. 4) Keep the publication format as online PDFs which folks can choose to print if they so desire. 5) Don't invest in "value added" extra content such as hosting instructions, guides, forums, etc. Your content contributors can offer to host those extras if required/desired--the magazine can point readers to the right place. I hope haven't been too pessimistic and discouraging of this effort. Personally, I would love to see a publication like Railbricks succeed in this space and continue to be the champion for showcasing the fun, the creativity, and excellence possible with enjoying model trains made from a simple general purpose brick building medium. It really is quite magical what some folks can build! I know someone else mentioned l-gauge.org; however, as its curator I am quite happy to continue hosting useful, general purpose content to our hobby. If anything, to reduce the burden to others for providing "value added" content.

-

Wow! These track component concepts are just fantastic! That switch looks absolutely gorgeous! I love the idea of using standard flat bottom rail extrusions threaded into rail chairs/clips moulded on to the sleepers/ties. The use of fishplates as rail joiners is also excellent. I bought a bunch of code 250 flat bottom Aluminum rail sections a while ago with the intention of scratch building some track (maybe switches) but haven't gotten around to it. I think any future metal rail product for L-Gauge is best off using off-the-shelf rail extrusions, either code 250 G-gauge or code 200, 124 O-Gauge. The magic is then the design of the plastic sleeper/tie components so that a variety of track elements can be assembled. Great work!

-

New Track Planning Library for BlueBrick

michaelgale replied to michaelgale's topic in LEGO Train Tech

BlueBrick Track Schematic Library v.1.1 Update by michaelgale, on Flickr I have updated my BlueBrick schematic track library to version 1.1. It incorporates the following updates: 1) Added RC/9V R40 radius half curves 2) Added RC flex track components. Head over to http://www.brickdimensions.com/resources/trains to download this latest version. Enjoy! -

New Track Planning Library for BlueBrick

michaelgale replied to michaelgale's topic in LEGO Train Tech

You are correct, I did forget the flex track! I am not a big fan of the flex track elements and don't think I would use them myself. However, for completeness, it should include it--very likely in a new revision of the library. In the meantime, the 1/4 length straight element can be used as a close substitute. Also, their is a flex track element in the BlueBrick "Track" library folder which can be used as well. -

Now that ME Models is shipping its much anticipated alternative Lego train track components, I really wanted to see what sort of layouts could be built with these elements. Many of us use the superb BlueBrick software tool for designing layouts both for individual and collaborative use. BlueBrick does not have library support for ME track components and therefore, I decided to make a custom library add-on for BlueBrick to include ME track. I have created two BlueBrick compatible libraries to assist with train layout planning by expanding the range of elements available for design. ME Models Track Components - This can be used as an expansion pack for the existing BlueBrick Track parts library. Simply extract the downloaded archive into the pre-existing \parts\Track folder. Complete LEGO® Train System Schematic Elements - This is completely new library developed specifically for symbolic or schematic track planning. It is a complete library including track elements from LEGO®, ME-Models, as well as custom track elements such as stub-switches and crossovers. The library is freely available for download at my website at: www.brickdimensions.com/resources/trains ME-Models library: BlueBrick Library for ME Models Track by michaelgale, on Flickr New Schematic Track Planning Library: Universal Track Planning Library by michaelgale, on Flickr BlueBrick screenshot with schematic track planning components: Universal Track Planning for BlueBrick by michaelgale, on Flickr

-

As I said before: nicely done! I will have to build my own version in regular green which is close enough to the prototype since it's livery varied quite a bit. Some clever solutions you worked out--probably better than the original!

-

I wish I had discovered this topic sooner! In any case, kudos to Steve B for taking the initiative on this! altBricks is one of the complementary manufacturers of alternative parts that we are lucky to have, especially for the under-served Train theme niche. I voted for 9V 88-stud radius curves, if only selfishly for preferring metal rail. Folks campaigning for plastic track make very good arguments for it making the best commercial decision at least for the first product offering. I'm a relative late-comer to Lego trains (having been a scale model railroader before) and did start out with RC track/trains (around 2011). Since last year, I've switched over to 9V, acquiring what I can from various 2nd hand sources. I have also been progressively fitting my locomotives with NMRA DCC control. The idea is to bring the standardized, proven, and sophisticated technology from model railroading into Lego trains. This of course demands metal rail and metal wheels--an increasing achilles heel since the supply of Lego 9V track and motor bogies will only continue to decline or become subject to irrational "collector economics". I am very supportive of this initiative, if only to encourage more enterprising folks to fill other niche gaps in the Lego train theme. The fundamental appeal of Lego trains is the fact that we can scratch build virtually any prototype from any era and locale using the same palette of brick elements. The only weakness that underpins the Lego train hobby is the availability and crudeness of its fundamental elements, i.e. the wheels and track. More complementary products in these two vital areas would serve to bolster interest and greater legitimacy of our hobby. In particular to those builders who adopt the same prototypical scale model railroading sensibility to Lego trains. Almost every other model train scale from Z to Gauge 1 uses metal rail to deliver electrical energy to trains with metal wheels. Furthermore, model train manufacturers and modellers have been increasingly adopting DCC (Digital Command Control) as the dominant control system standard due to its operational flexibility and support of sophisticated lighting, sound, and accessory effects. The Lego train hobby would benefit immensely if it could embrace the same technology basis as its scale model train peers. I don't want to veer too much off this valuable topic thread because fundamentally Steve B needs to know what product offerings are going to yield the best commercial success, i.e. reflect what we want! I will however conclude with a few personal opinions on what principles/products I would like to see offered in the Lego train hobby market: 1) Compatibility with the 5-stud gauge/0.250" rail height geometry of Lego 9V/RC track. 2) Track geometry which adhere's the relatively standard 16-stud centreline interval spacing. 3) Metal track options 4) Metal wheel set options: i) technic wheel with cross axle and metal tyre (form-fit-function replacement for existing) ii) steam wheel/blind with cross axle and metal tyre 5) Metal wheel pickup wiper parts with stud attachment 6) More track assemblies: switches, diamond crossings, slips, cross-overs (16-stud CL), scissor crossings, etc. Even a new switch with geometry which supports a 16-stud centre cross-over--perhaps the most ubiquitous track switch configuration in the world! With metal wheels and wiper parts, we can continue to use existing PF motors and bogies in locomotives yet benefit from electrical control via the track. This would give the choice to use 9V, variable DC, or DCC control systems as desired. If I win a lottery, I promise to launch a commercial venture to give us these options ;)

-

Matthew, Thank you for your prompt follow up. No apology is required, since at no time were you commercially exploiting my creations. I simply wanted to go on record saying that I did not endorse commercial use of my creations. Thank you for your kind words regarding my creations--that is appreciated. I still have a lot to learn, and continue to do so by admiring the techniques used by many other Lego train builders. You should not underestimate your own skills--the fact that you were able to faithfully recreate some of my creations suggests that you possess more skill than you give yourself credit for. I am more than happy for you to copy my creations for your own layout! We all at some point copy ideas from others--that's how we learn--and that is how we can discover new improvements or techniques. Thanks again, and I look forward to seeing more of your own creations. At the end of the day, we do this to make cool creations and have fun! Michael

-

As flattered as I am by having three of my Lego wagon designs laboriously reverse engineered, reproduced and spotlighted on this forum; I would have preferred to have been asked first. I support fair-use efforts to create derivative works from others; however, these three wagons you see here are not simply derivative, they are direct copies. I don't mind people copying my creations to build for themselves--the reason we share our MOCs on flickr is to inspire and to learn from others. I do draw the line at selling or deriving commercial benefit from my works. Its similar to open source software--depending on the license, we are free to copy/modify/make derivative works; but often we are not permitted to derive commercial benefit. I would invite other folks to visit my flickr pages and judge for yourself whether these wagon designs are derivative variations, or simply copies... Hopper wagon : British Rail HEA wagon : Open wagon : British Rail OBA wagon : LDD render : Open wagon : British Rail OBA wagon : Brick build : Brake van : British Rail ZUV Shark, engineers ballast plough : (incidentally, the brake van version you see represented on this page in grey/red never did exist in the prototype. The plough brake van was exclusively used by BR engineering works for ballast and track maintenance. Therefore, the liveries worn by this wagon include either bauxite brown, olive green, grey, grey+yellow band, and in later years, Load/Haul black/orange, and EWS. Rail grey/red was the livery used for Railfreight rolling stock)