sjim

Eurobricks Vassals-

Posts

25 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Everything posted by sjim

-

That's how Swedish railway signals work. https://en.wikipedia.org/wiki/Swedish_railway_signalling While I may be biased, this signalling system is one of the most straightforward I've come across. It has the option of using 2-5 lights and still gets a lof of information across.

-

Big or Small

sjim replied to TechnicRCRacer's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Mine usually end up large... :) -

DIY Cheap Motorized Track Switches (no cutting/glue)

sjim replied to Phoxtane's topic in LEGO Train Tech

But... This is amazing. :P I have been trying to find a good solution for a year, but the measurements are really wonky, the torque required is high and the bottom of the switches are really fragile. Thank you!- 16 replies

-

- switch

- track switch

-

(and 3 more)

Tagged with:

-

I had the same problem some time ago. After some testing I found that the wheels on the locomotive that are put in a technic fram got pushed together when driving over switches "backwards". This created a lot of friction and resulted in the behaviour you describe.

-

Gauging Interest: Control Board for Two Three-Aspect Signals

sjim replied to Phoxtane's topic in LEGO Train Tech

Ah, you are right of course. Did not think about that. :)- 14 replies

-

- signal

- three aspect

-

(and 5 more)

Tagged with:

-

Gauging Interest: Control Board for Two Three-Aspect Signals

sjim replied to Phoxtane's topic in LEGO Train Tech

I really like the idea, and have tried to do something similar myself. For my part I don't think I would buy it. Some of it is the cost, but mostly because I would need to have two lights (A1 + B1) on at all time and sometimes three lights (A1, A3 + B2) and it seems that this could cause issues. If I were to buy this kind if product I wouldn't want to risk frying it by mistake because of a bug lighting up all LEDs. Maybe this could be solved with transistors with little additional cost? In any case I love the simplicity of it. Also, making it 4 x 4 studs is brilliant. I would also consider naming the outputs LED1, LED2... as most countries do not use signals the way cars do. Keep on programming!- 14 replies

-

- signal

- three aspect

-

(and 5 more)

Tagged with:

-

I adjusted the switch to use a small pneumatic cylinder instead, and also I put pictures of the building process. Check it out and let me know what you think: http://greytag.se/lt2/pneumatic-switches/

-

Thank you for your interest and feedback! That is correct. Pneumatic cylinder -> 2 x liftarm (arranged in an L-formation) -> 8 tooth gear -> gear rack I tried the small cylinder, but failed. I can't remember why at the moment though... :) I'll probably have another go at it soon enough. If I had seen your pictures before I might have gone that way. It looks brilliant! I'll have a try with pneumatics one day. I found that the only way to get it done by motors was to build an enormous 'holding cage' to ensure that the power needed didn't break the construction. In the respect I have to say that baard put me to shame in a brilliant way. :) In my experience there is no way to have reliable automatic switching without raising the track. The bottom is too weak. The CAD part is not where I excel. I'll get some more photos posted in various stages of building, no problem. :)

-

I have long tried to make a mechanical switch for my Lego trains, but never got it to work properly. Part of this has been that the underside of the switches has been too weak. The resolution so far is pneumatic switches. You can find a video here: If you want to see some pictures and download the ldr, go here: http://greytag.se/lt2/pneumatic-switches/

-

Thanks! Thanks! Your video was one of my main inspirations, but I lost the link. :( Now that I have it, I will link it from my page. The short story of the funding is that Helsingborg City wanted to add a creative place to the festival. A group I'm somewhat involved with was tasked with this and a few of my friends got some funding for an AR-project (The Sandbox). This project fell through however, and I suggested to replace their project with Lego trains and got the funding. So a bit of luck and guts. :P The AR-project and an additional copy was produced and shown anyway by the same team to I got some trains, the city got three (!) projects and people got to build their sandboxes. Triple win!! http://www.creativelab.nu/program-utstallare/

-

Thanks! Agreed! I tried, it's on the list of iteration 2. :) Absolutely!

-

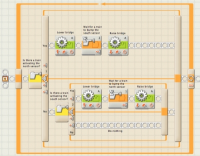

Some time ago a group I'm engaged in got some money to create projects for our city festival (sort of). For a bunch of reasons one of the main projects fell through and we needed a replacement. I suggested a display with Lego trains controlled by Arduino. Last week was presentation time. It's a first iteration so I wanted to make it simple yes a fit fun to look at. The trains go in opposite directions in an oval. There are two stations where the trains either wait five seconds or wait until the upcoming track part is clear. If the waiting time is up and there is no other train in the way it's go-time. Since the trains go in opposite directions, the switches can be static. You can check out a more in-depth description on my site: http://greytag.se/lt/showtime/ Let me know if you have any questions or comments.

-

Trouble with nxt programming

sjim replied to KDM's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

No problem. Have fun! Don't forget to post a video so we can see your creation. :)- 12 replies

-

- Nxt

- programming

-

(and 2 more)

Tagged with:

-

Trouble with nxt programming

sjim replied to KDM's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I am going to use north and south entrance instead of A and B as this seems to be a bit confusing. I hope that's ok. This is the easiest program I can think of: - If the north sensor is pressed --- Yes: Lower bridge, allowing trains to pass --- --- Wait for south sensor to be bumped --- --- Raise bridge --- No: Is the south sensor pressed --- --- Yes: Lower bridge, allowing trains to pass --- --- --- Wait for north sensor to be bumped --- --- --- Raise bridge --- --- No: Do nothing I have attached an image of the program. If you like, PM me with your email and I can send the .rbt file to you.- 12 replies

-

- Nxt

- programming

-

(and 2 more)

Tagged with:

-

Automatic pneumatic pump

sjim replied to sjim's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I updated the design to use a bigger arm to connect the to the trigger and now it work ok. Thank you all for your inputs! -

I have an issue. At the moment I am trying to make an automatic pneumatic pump. The idea is to have a M-motordriving two 6L pumps. When the system, including a airtank, is full a small pneumatic cylinder press a powerfunctions switch to off. When the air runs out a rubber band pulls the cylinder back and the switch goes on again. The problem I have is that I can't seem to get the rubber band right. Usually it is too tight to allow the cylinder to extend or to loose to press it back again. Sometimes it is too tight and too loose at the same time. I may be losing my mind here, please save me.

-

I am looking for some inspiration from the board. I am trying to build a warehouse robot a bit like this one: http://www.dreamstime.com/royalty-free-stock-images-automated-storage-robot-warehouse-blue-plastic-crates-image34142419 At the moment I am stuck with the movement of the carriage. My problem is that I do not want the motor to be on the carriage itself and need to transfer it somehow. I have tried using a chain to pull it, but it doesn't seem to work very well. Sorry for the poor images. It's not a good place to take them. Also I don't know why they are upside-down. I'm looking into that.

-

I am trying to make my Mindstorms NXT communicate with an Arduino board. The final project will be a warehouse robot that checks the colour of the contents on a pallet and stores it on a shelf. You can then order a number of pallets in different colours and the robot will get the order on a first-in-first-out basis. The inventory will be kept on the Arduino board along with the ordering interface and the Mindstorms will do the colour checking. New pallet operation: (NXT) Senses the pallet (NXT) Checks colour (NXT -> Arduino) Notifies the Arduino of a new arrival and its colour (Arduino) Finds a suitable location (Arduino -> NXT) Notifies the NXT of column and row (NXT) Puts the pallet in place (NXT -> Arduino) Sends an ok message (Arduino) Updates inventory Order operation: (Arduino) User creates order (Arduino) Checks which pallets to use (Arduino -> NXT) Requests NXT to get pallet (NXT) Delivers pallet (NXT -> Arduino) Sends ok message Step 3-5 is repeated for every pallet in the order (Arduino) Updates inventory What I can do at the moment: Connect the two manually Send single characters from the NXT to the Arduino What I would need input on: Sending information from the Arduino to the NXT At the moment the two units seems out of sync in some ways. The information sent from the NXT to the Arduino is sometimes picked up and sometimes not. I an guessing this has something to do with the Wait block and the delay() function. I am using the blocks for sending and receiving messages on the NXT and I am using Serial.write() and Serial.read() on the Arduino. The bluetooth module is an HC-06 ( http://www.kjell.com/sortiment/el/elektronik/mikrokontroller/arduino/bluetooth-transceiver-p87942 ) and I am using an Arduino Uno. I have found some information when searching, but many are specific to an alternative NXT language.

-

- mindstorms

- nxt

-

(and 1 more)

Tagged with:

-

Got a tracking number now, so I guess your fingers did their magic. During the process the free thingy seems to have been dropped. I am nog going to point this out to anyone however as to not upset anything.

-

I just wanted to update as some things has happened since the last post. First I would like to say that the girl I takled to from U.S. was called Lucy, and while she couldn't actually do anything she was very nice and professional. A girl from the Swedish customer Service, Lizette, called me and explained the situation to me. I have to admit that I wasn't really receptive of a long explanation with no solution, but after som talking she said she was going to try and order it again, several times telling me it was a test and not a sure thing. Cred to Lizette too for keeping positive in a no-win situation. So the order has gone from Backorered to In process. Do anyone know if this is good or bad? As far as telephones go, I seem to have had som bad luck with this. Strange that Tre and only Tre would do this.

-

Well... Min was cancelled. The order status was changed to "Please Contact Customer Service". I got no notification of this... I emailed and was told to call. I was unable to get hold of them because landlines are basically extinct in my family and closer friends. When I contacted them about this I got no reply. Today I realized I could try the U.S. number through Skype but my order was cancelled because I did not contact the in time. Needless to say the 41999 is sold out. I won't get one and I certainly won't shop at a store that treats me this way again. Sad. I really like LEGO, and was looking to start going exclusives.