-

Content Count

794 -

Joined

-

Last visited

Posts posted by z3_2drive

-

-

Ok, back on topic, have you tested the female ball gear adapters yourself, effe? So far they've handled pretty well but I've yet to really punish them out on the road, I will let you know soon. They already feel stronger than the Lego as well as the printed u joints.

-

So we know the 'rumored' set names and piece counts but the prices are not assigned? All I would want from a supercar is a nice gearbox which we've been missing for a long time, and hopefully some interesting new drive drivetrain/suspension parts. Without RC, it could be second in price with those number of pieces, but with RC, it could easily jump to first. And what's with knowing both 1h and 2h sets? Isn't the info usually split in time? Would this mean photos of both halves will be leaked similarly? I can only hope.

-

I would, but man it is expensive, and I have other hobbies I spend money on, so I work with what I have now

It's fun seeing how far you can push Lego, and you can use the same parts to make completely different things. I am reaching the end with my last few projects, though, and my current project will be the first of mine to use a printed piece. I guess I might move on, but that'll be a few hundred dollar investment and I'm not selling my Lego! On one hand, I love seeing people push the limits, and on the other, I love seeing purist MOCs using very creative solutions and fine aesthetics , including yours.

It's fun seeing how far you can push Lego, and you can use the same parts to make completely different things. I am reaching the end with my last few projects, though, and my current project will be the first of mine to use a printed piece. I guess I might move on, but that'll be a few hundred dollar investment and I'm not selling my Lego! On one hand, I love seeing people push the limits, and on the other, I love seeing purist MOCs using very creative solutions and fine aesthetics , including yours. -

The 3D printed parts are not really pretty (grainy or colors that never perfectly match lego) and I like them when they are used to explore an entirely new idea, not to make something easier. For example, I recently got a couple female ball gear CV joint counterparts (to fit the ball gears like in 8880 supercar) as a substitute to U-joints. Not because it's easier but because it simply won't work any other way, every single u-joint at the scale i'm building in WILL break with 2-4 buggy motors, either right away or after some time. So I get these to try and see if they will survive the strain. I will agree, simply making parts for easy solutions when lego solutions exist, takes the fun out of finding out purist solutions, but when there is none and the custom parts explore new levels of performance/function it's nice to see it. And of course MOCs using non lego parts are labelled as such, can't be used in contests etc, so it's just personal interest. I understand both opinions. Also makes me wonder if Lego will make new parts similar to the ones people design, such as bringing back CV joints using the old ball gears! It's so much stronger than a U-joint and works more smoothly!

-

The 1.55 Dirt grabbers are perfect for what I just finished building, but they are out of stock now :( Has anyone tested any tires in that scale that are also 75mm or less in size?

-

The picture with the body taken off almost made me tear up... This is an amazing MOC in all aspects, great job!

-

Why not pm the moderator, especially the one who last commented on that thread? Now you've made another thread which will have the same fate - closed because its creation was unecessary. It may be only one thread, but many of these kind of topics end up blocking out more important discussion, similar to bumping old topics to the front for no reason.

EDIT: Jim's response from the topic in question.

And a more general comment; do we really need a separate topic for this? We had this conversation in the 2015 Discussion and Speculation topic. Let's keep it there.There's your answer to be specific.

-

Correct me if I'm wrong but are the gear ratios different on the rear due to lack of differential? Other than that, awesome MOC!

-

Looks really good! Can't wait to see the finished model, reminds me of the good ole days playing DiRT 2...

-

Anyone who's built the model already, do you have a set of 41999 wheels to put on this masterpiece? Curious if it would look good.

-

It looks beautiful, and the functions are so unique, I definitely want to build this one

-

No, almost 12. Custom 3s battery and RC system.Are those buggy motors still running at 9V?

-

Probably, though some old generation muscle cars could fit the dimensions if flex axles are used.The only problem I have with it is how large the body is- even if you tried to put a body on it the top parts stick up too high.

I've never done an official speed test, but this was the previous version of my high speed chassis to give you an idea:This thing looks beastly! What is its top speed?

-

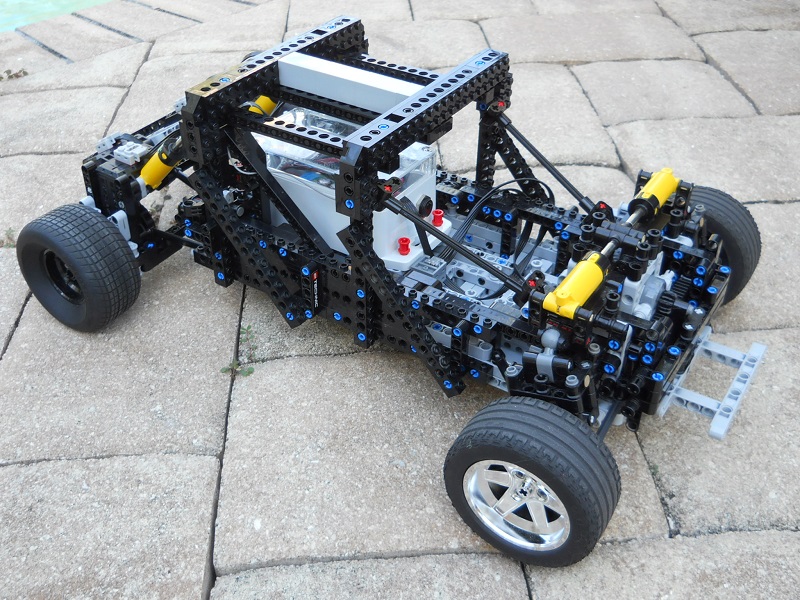

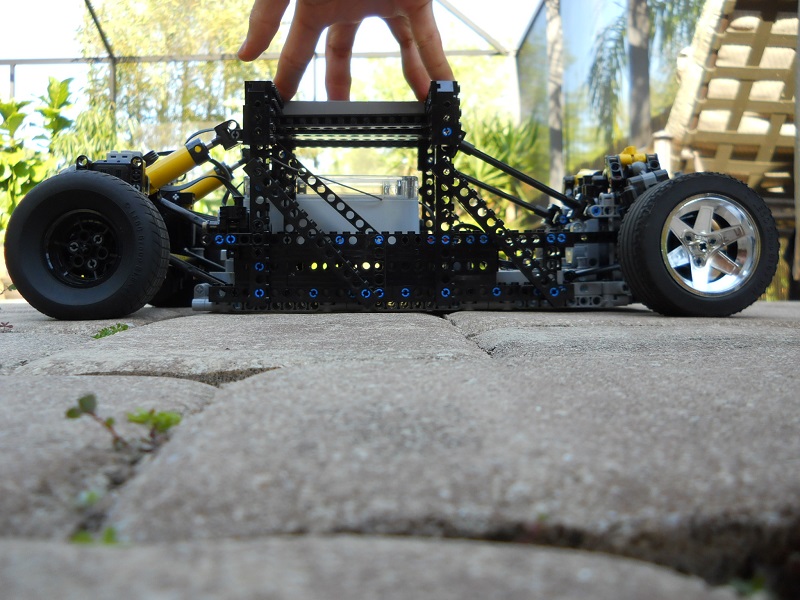

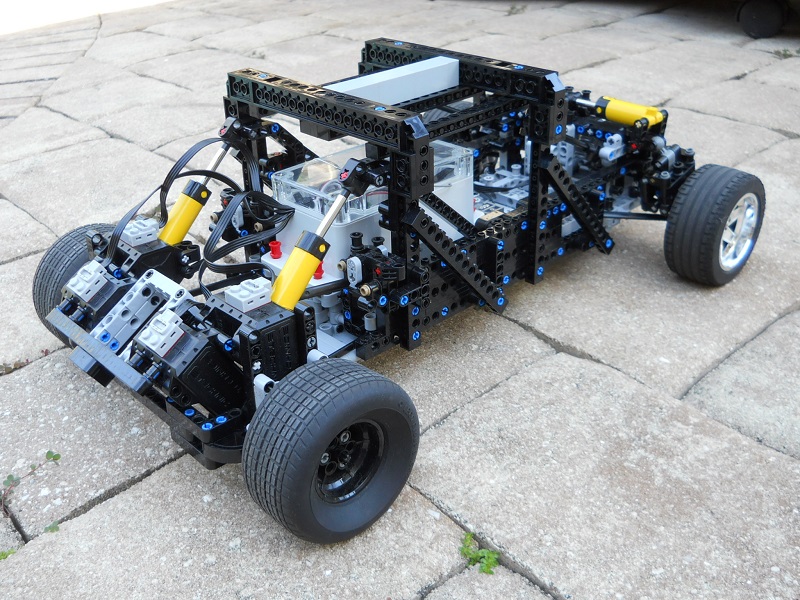

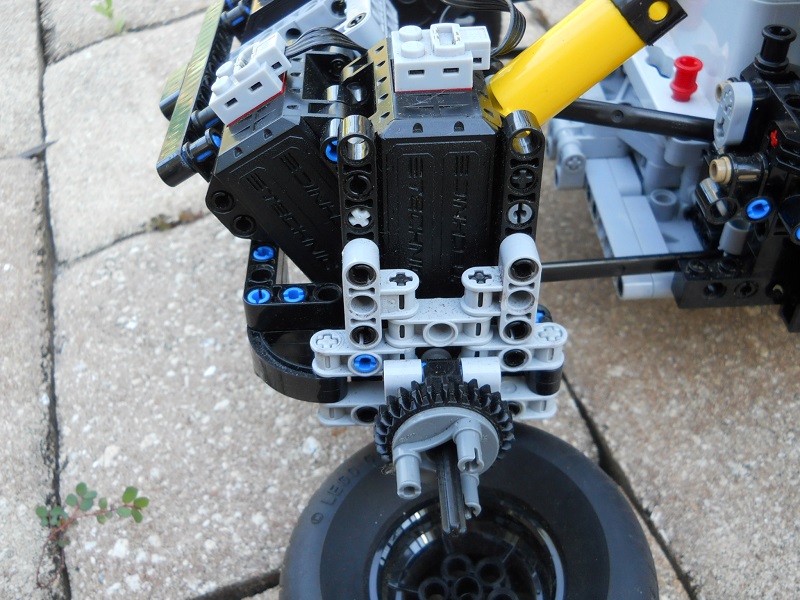

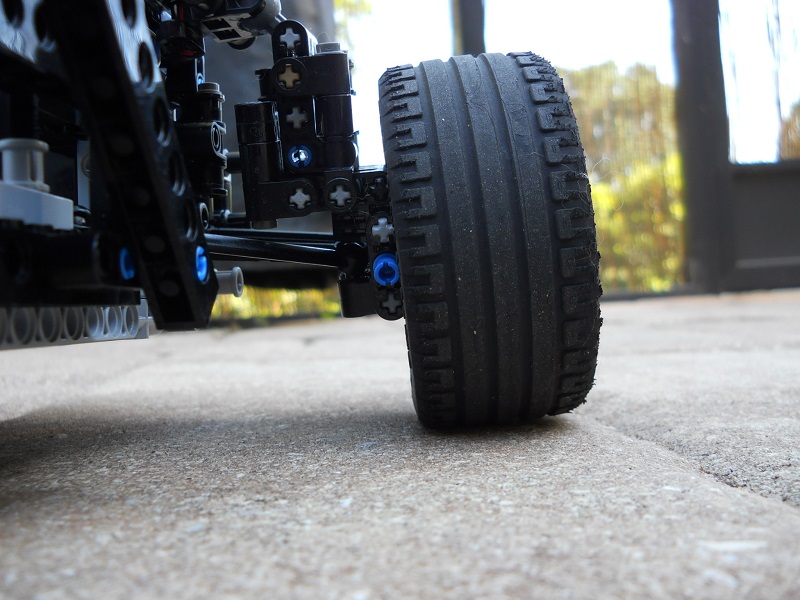

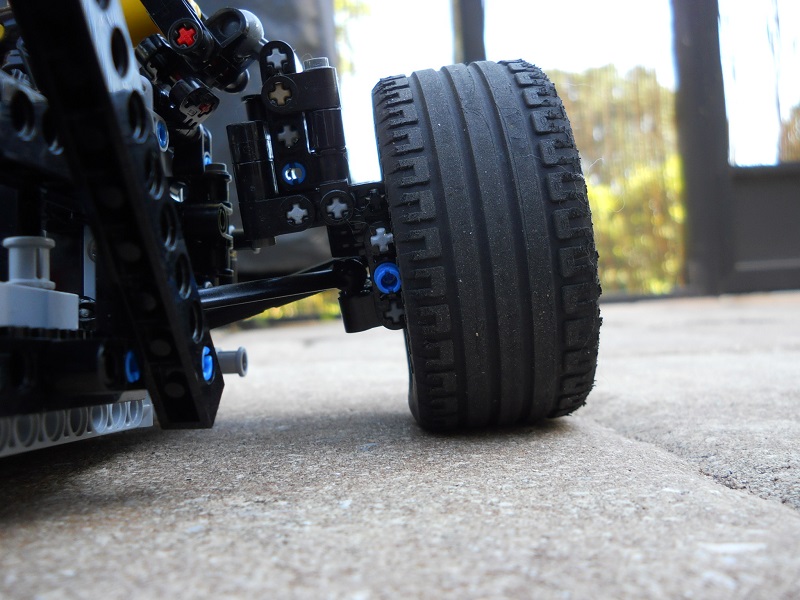

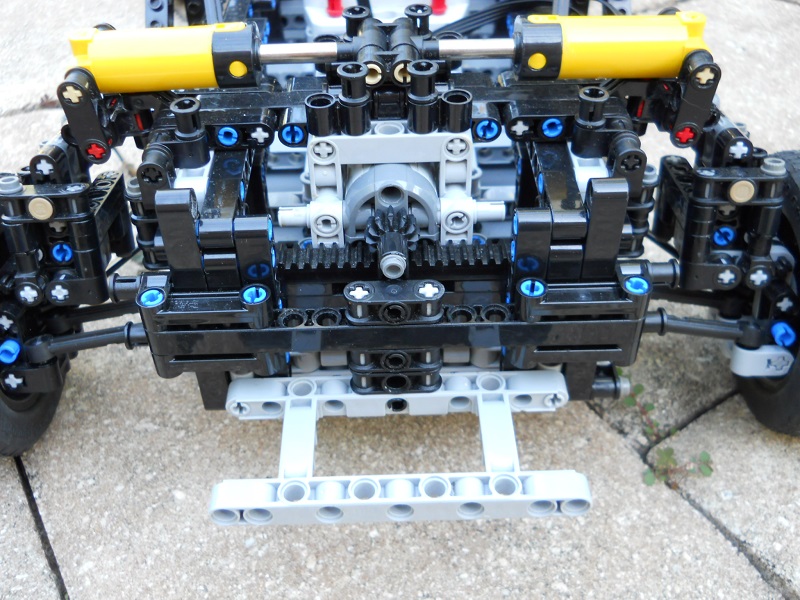

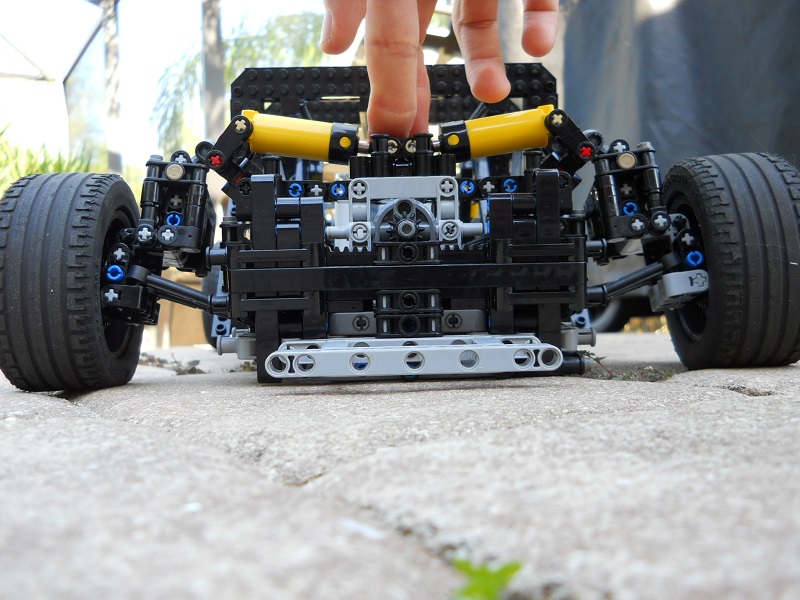

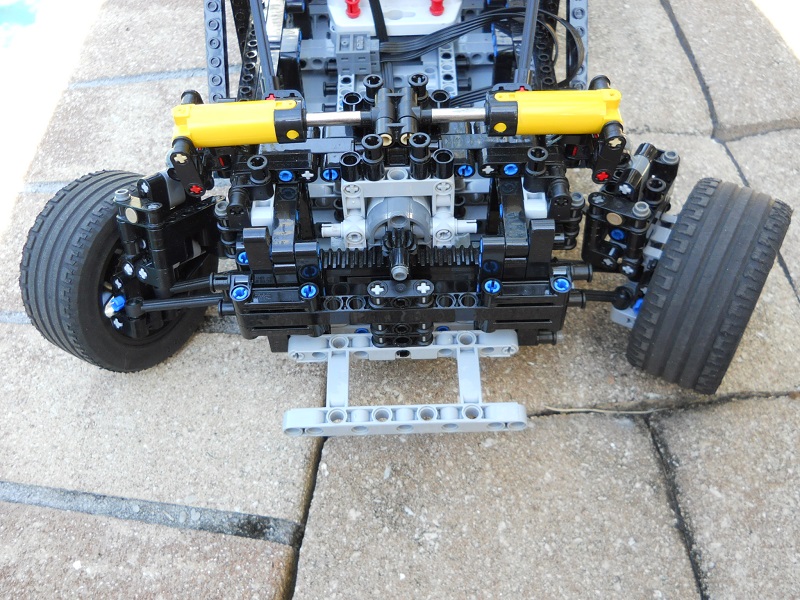

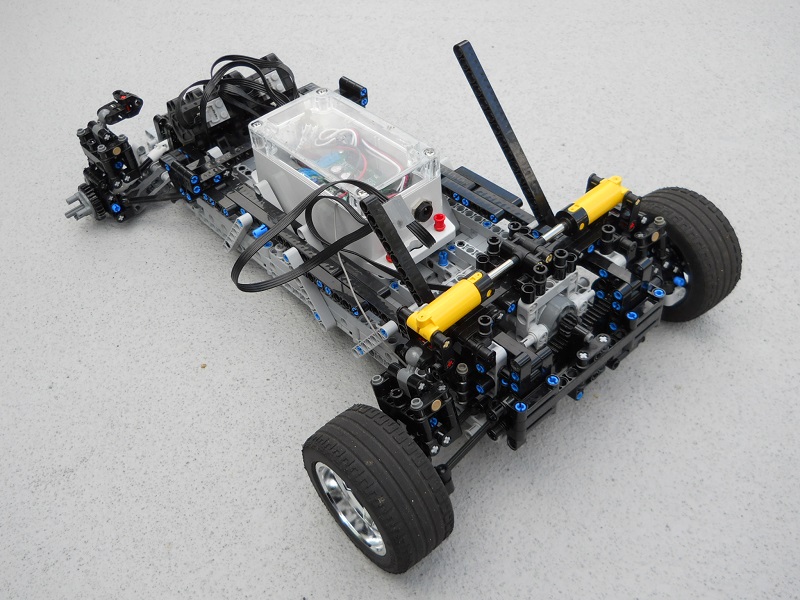

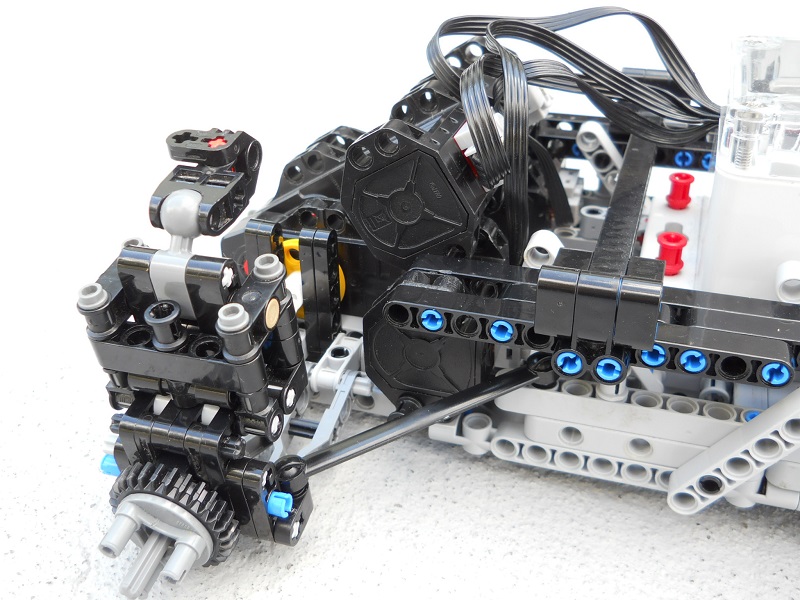

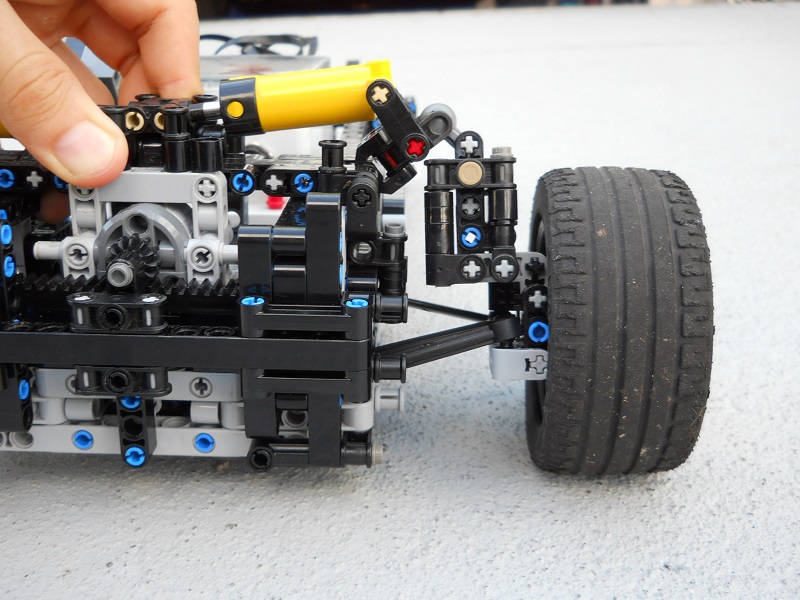

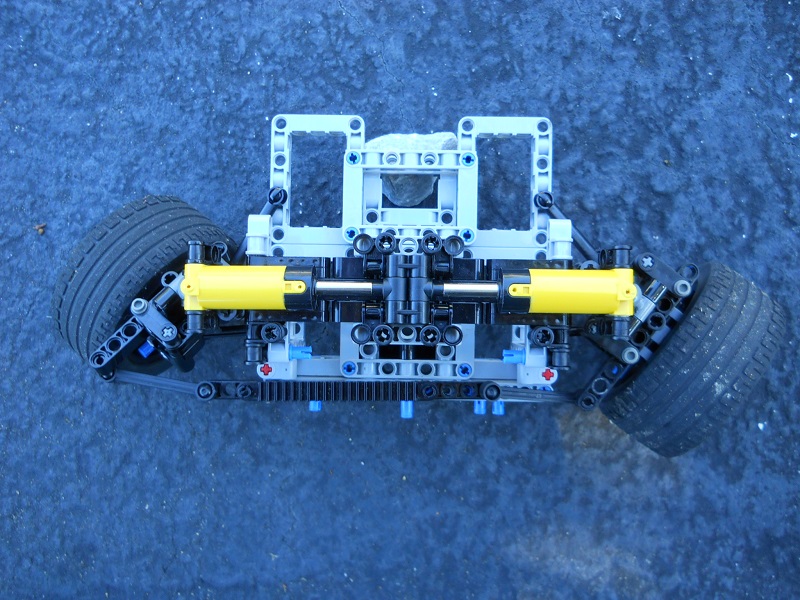

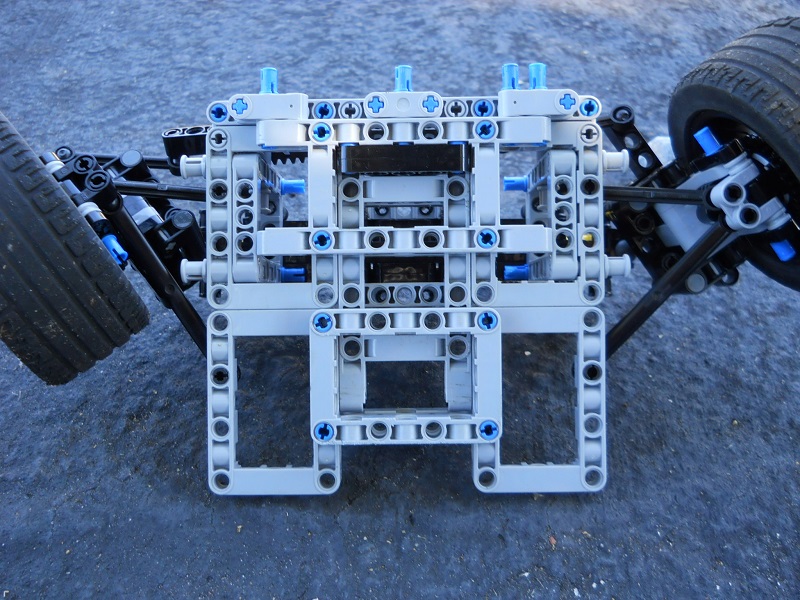

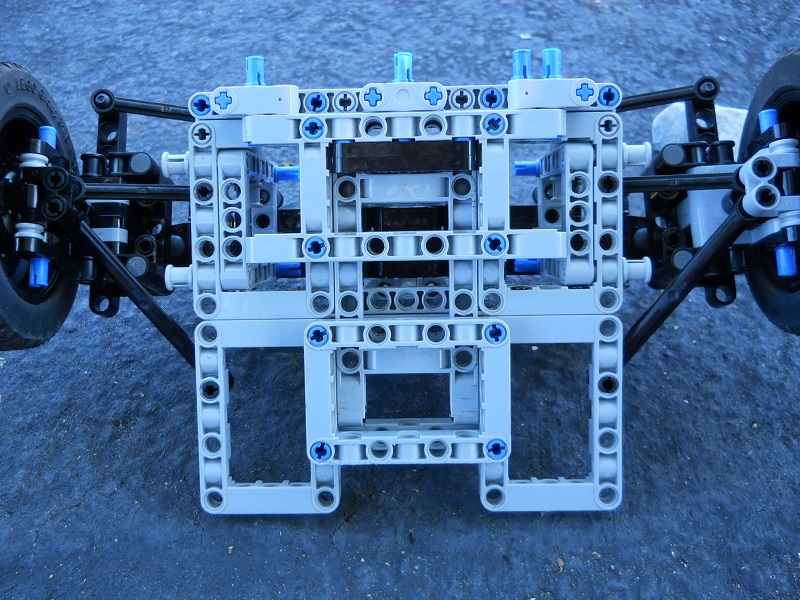

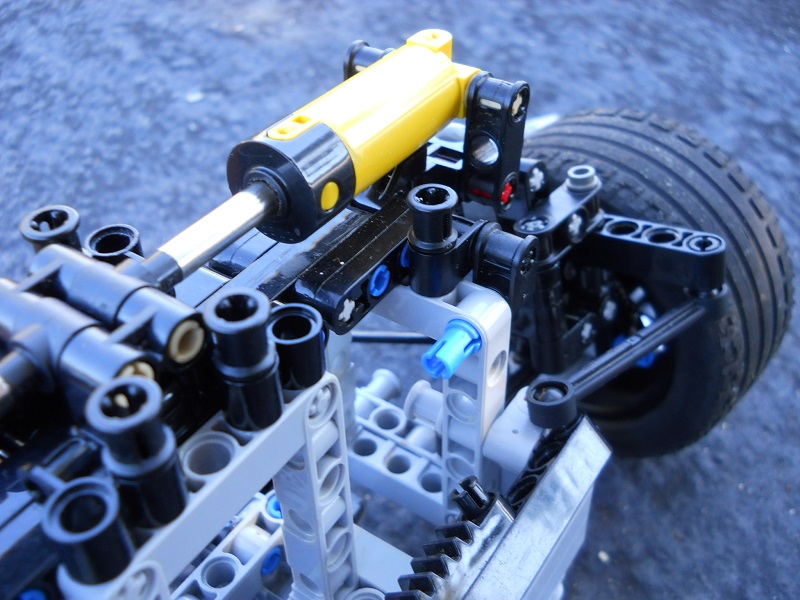

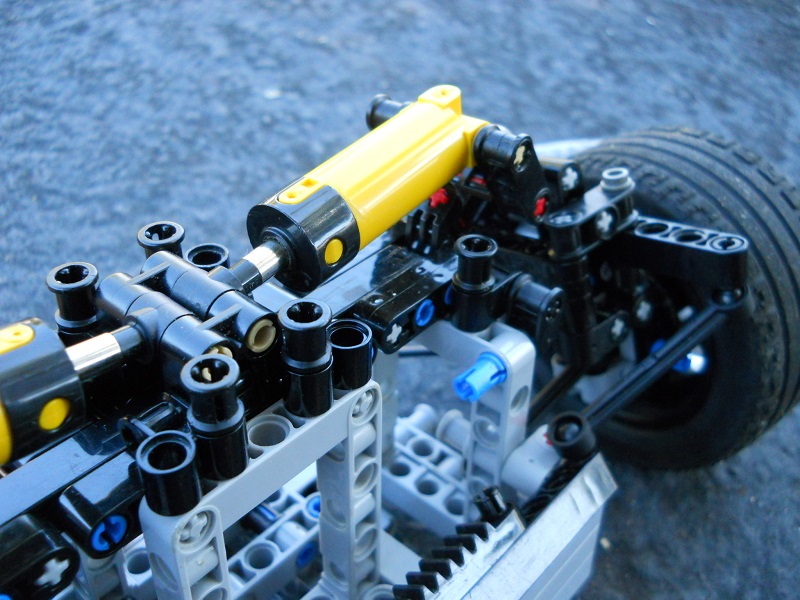

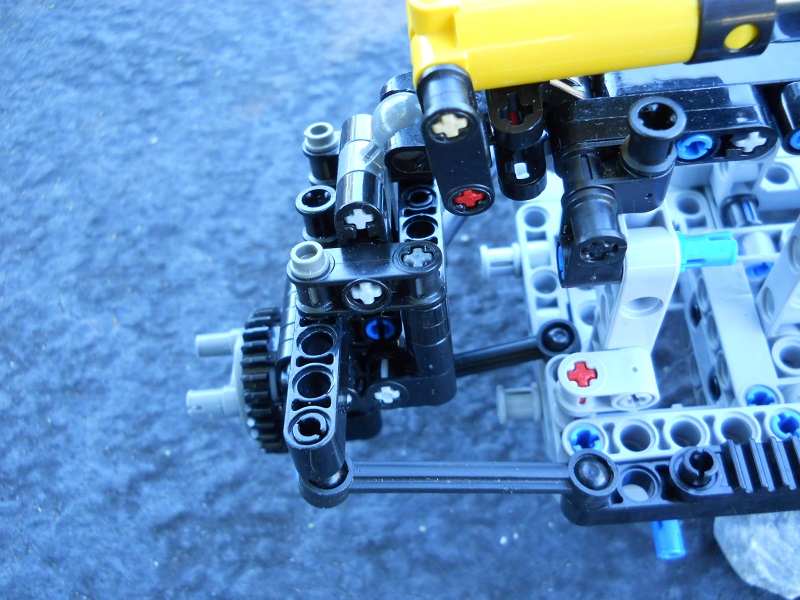

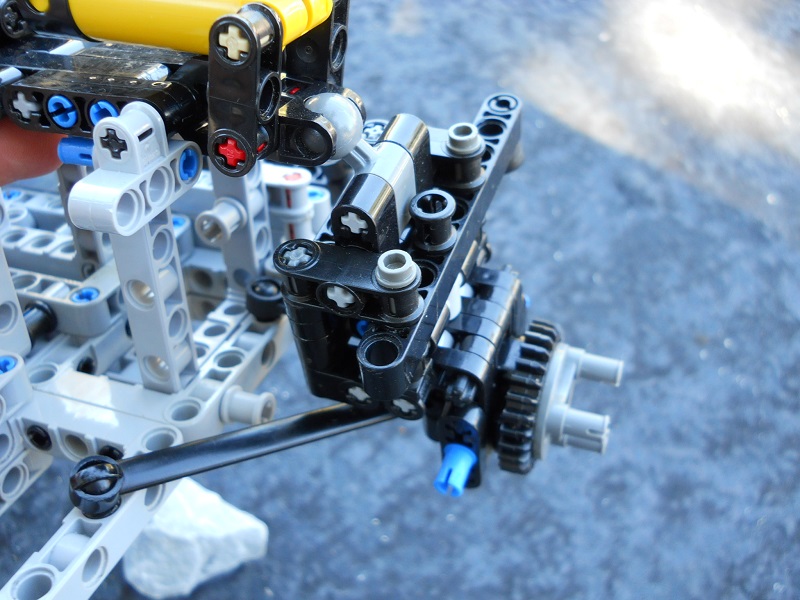

I haven't posted any of my own content recently due to lack of time and ideas, but about a month ago my last attempt at a high speed vehicle was sitting on my desk, partially disassembled, when I got a spark in my mind and I knew exactly what to do. Previously I made multiple failed attempts at making a complex independent suspension work, but I couldn't get a practical result without modifying parts, which I wanted to avoid. So this time around I went for a solid axle with 4 link suspension. I spent a long time building and rebuilding the car until I got a balance of power, weight, and strength that I was happy with. Apart from a couple pieces I forgot to add here and there, this is the final build:

I could have gone for lower weight, but the reinforcements were necessary to bring the chassis flex to a minimum, letting the suspension do its job.

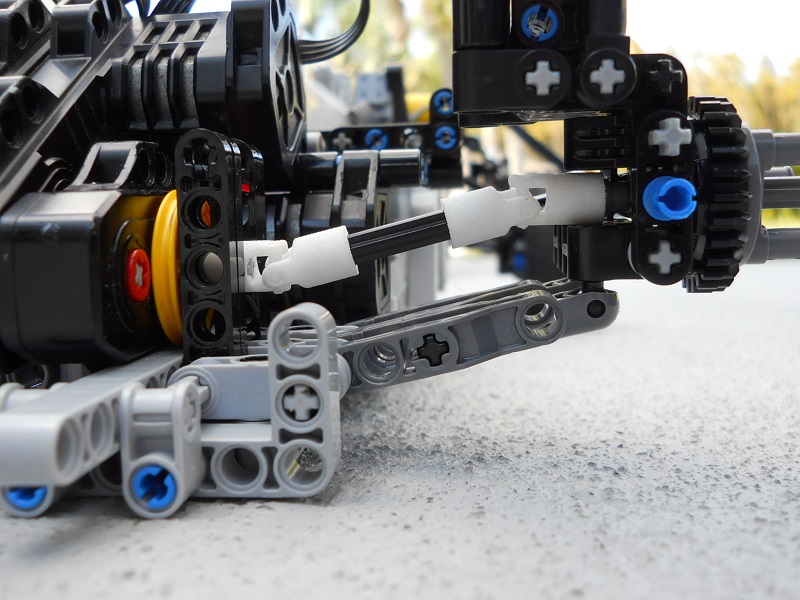

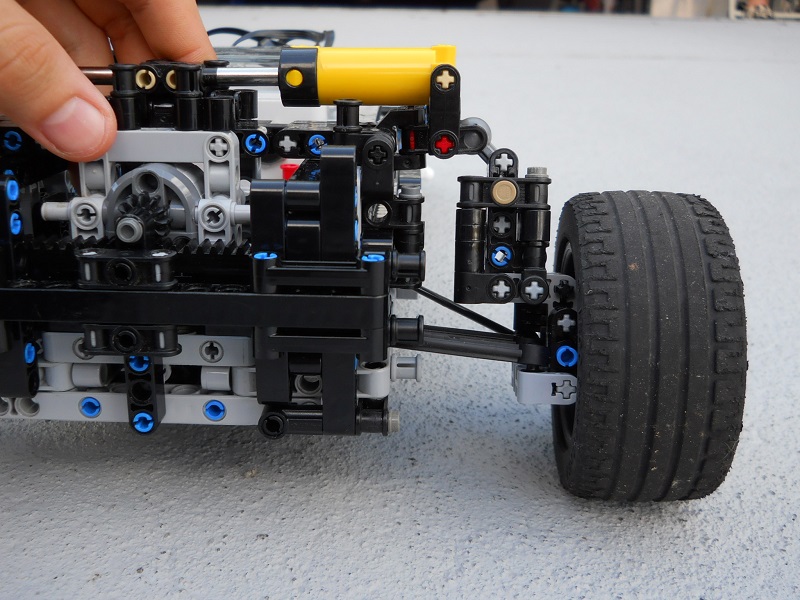

The car barely bottoms out under full compression, but I doubt this will happen out on the road. The higher clearance and lack of u-joints should reduce the risk of damaging parts.

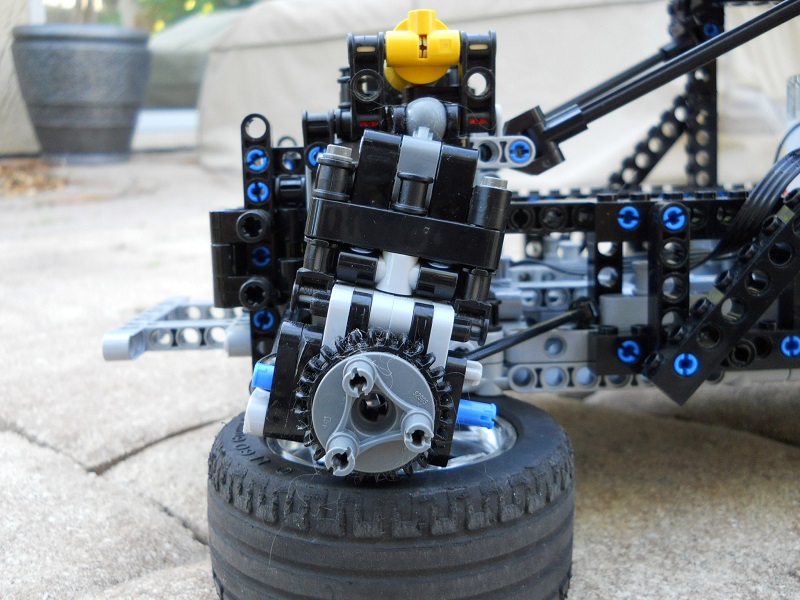

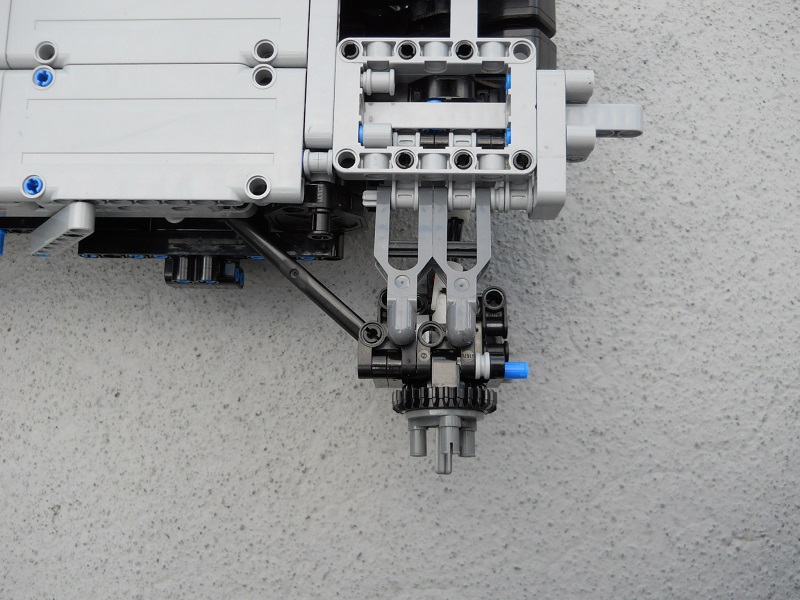

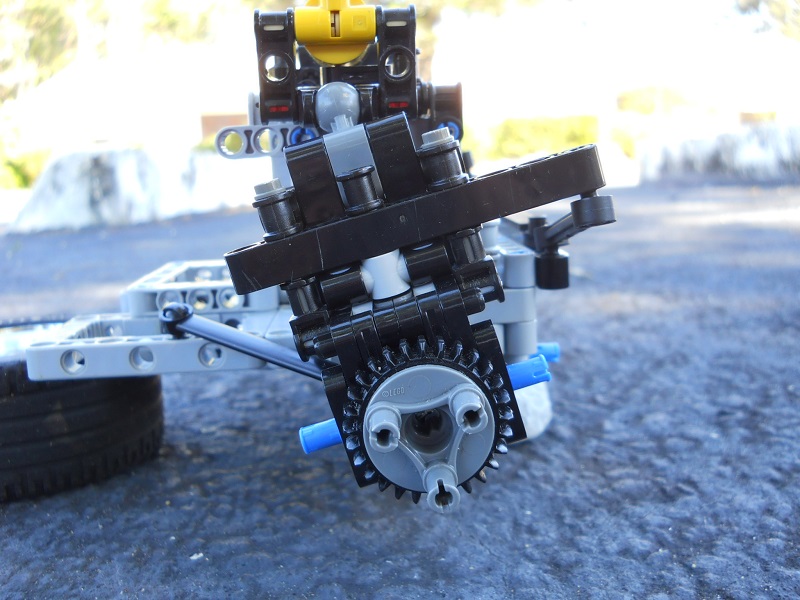

The rear wheels are driven by two buggy motors each, acting as an electronic differential. Since the motors are DC motors, this system will never be perfect, but it's as good as it gets.

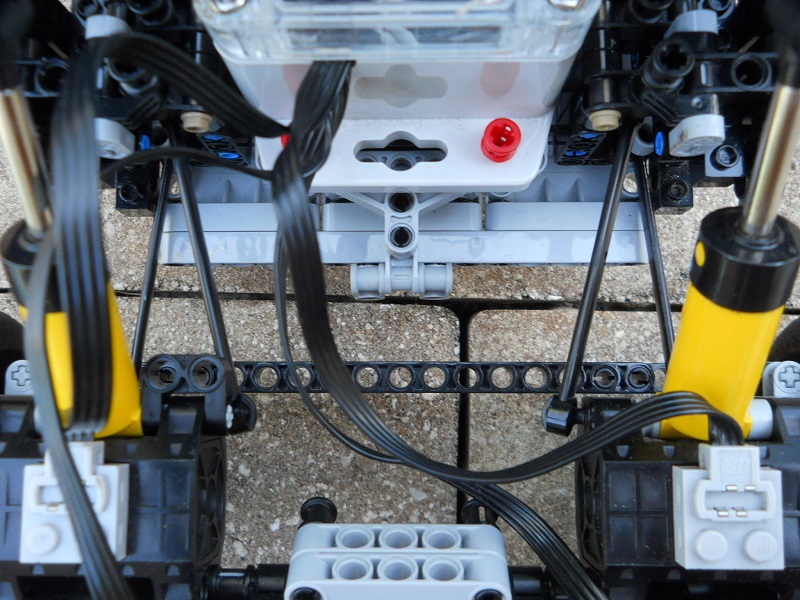

The only modified lego pieces on this build are the pneumatic cylinders (now act as dampened shocks) and the wheelhubs

(made by nicjasno at LPEpower )

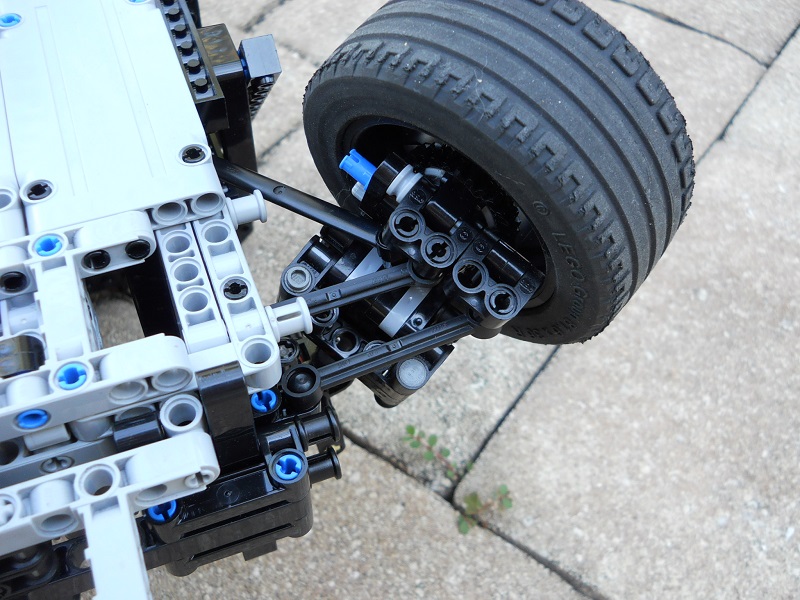

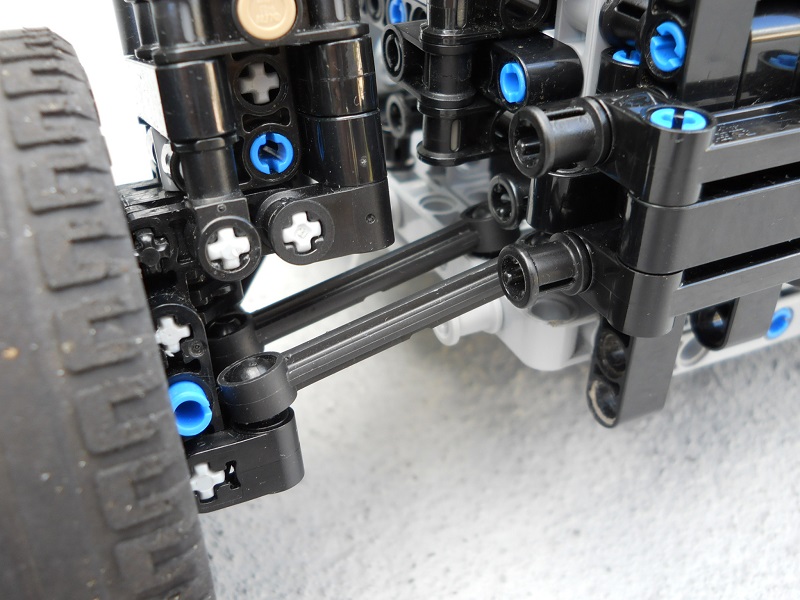

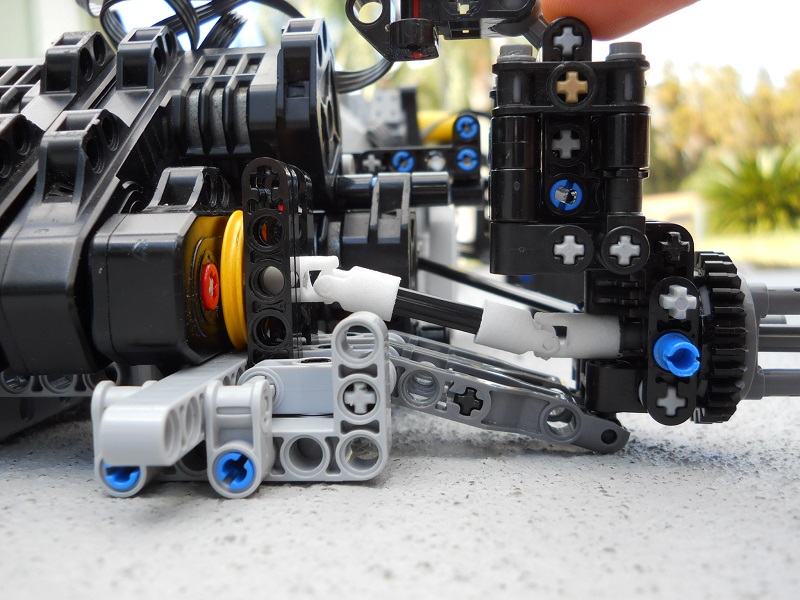

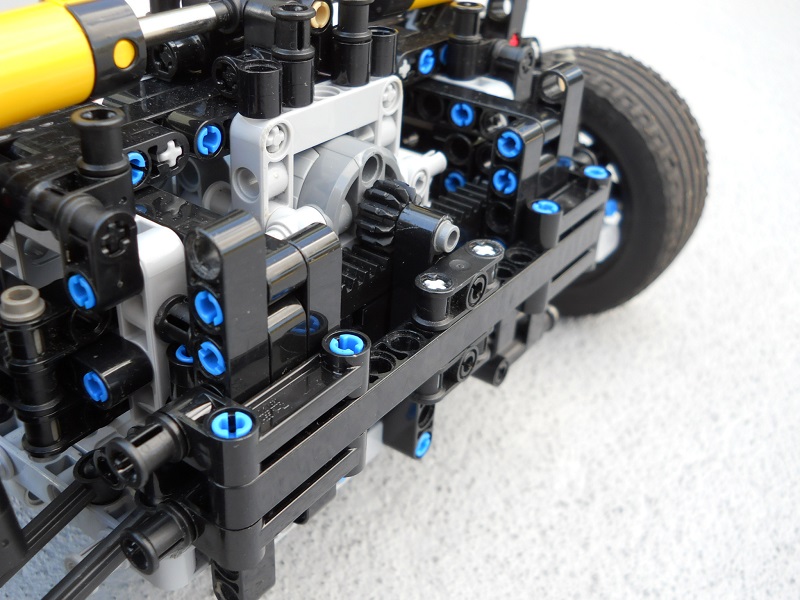

The front suspension is independent multilink, my own blend of various ideas I got from nicjasno's

Standard servo steering. I lubricated the large ball joints on the upper 'wishbones' to reduce friction.

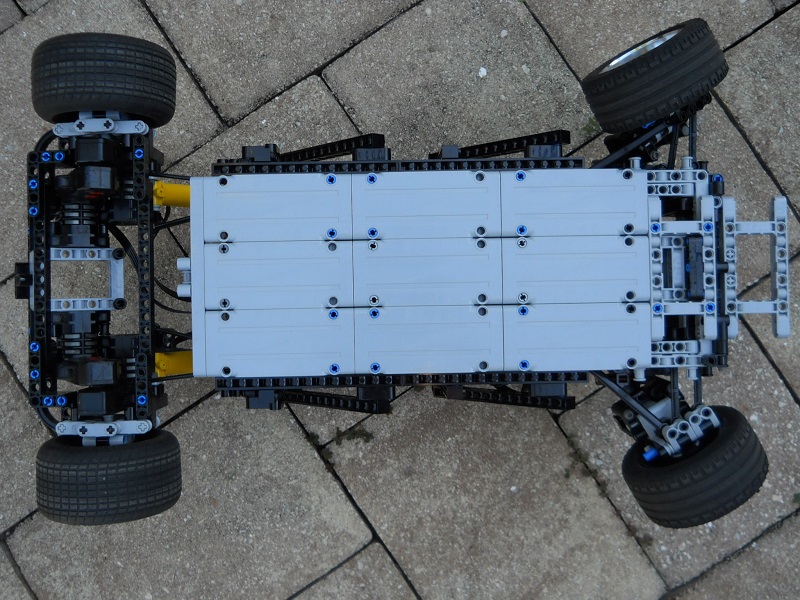

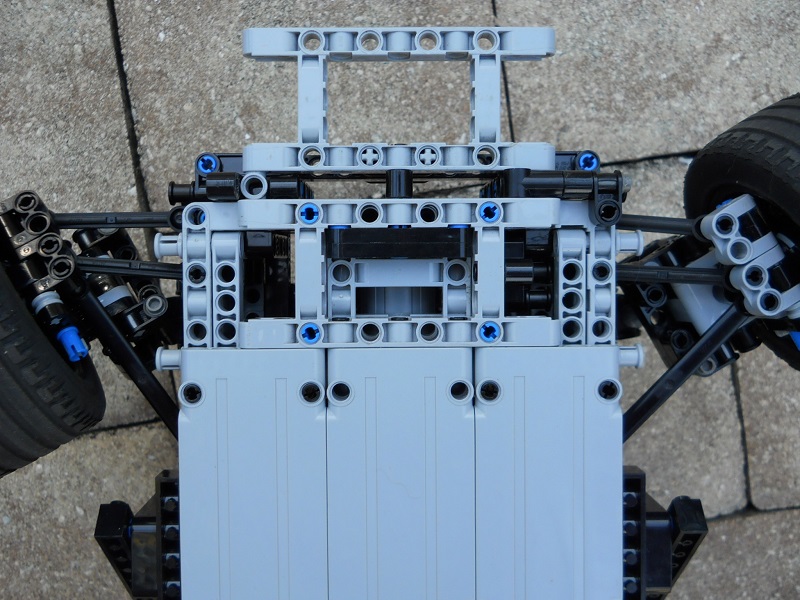

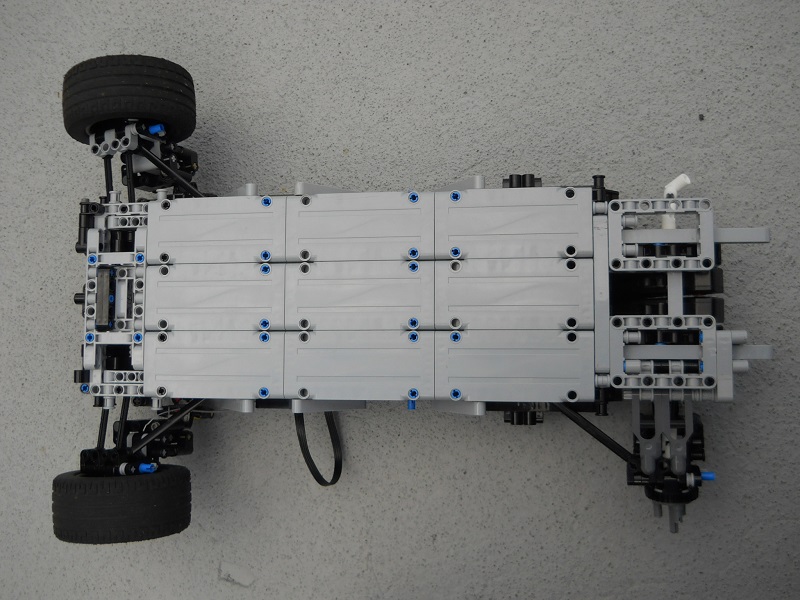

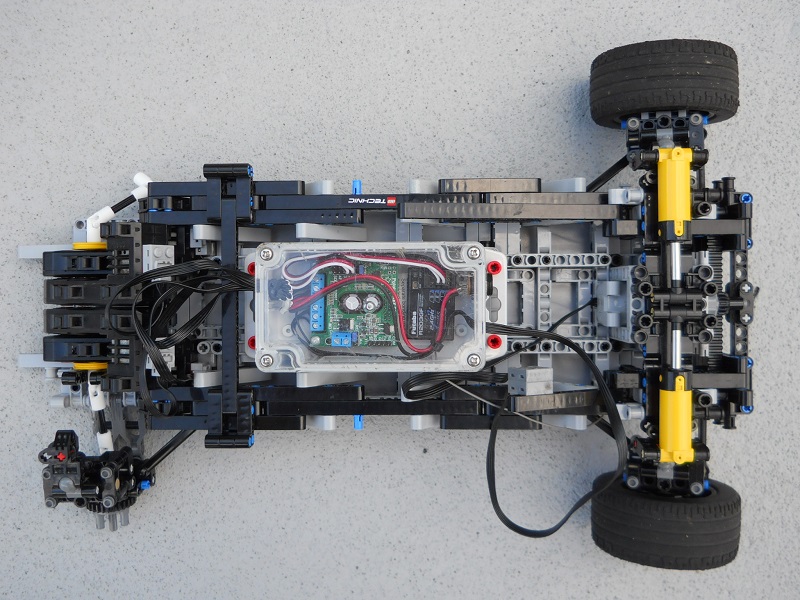

Nice and smooth underside, which also adds to the structural rigidity (note the numerous pins)

Another look at the multilink setup in action

I've already tested this model on the road, and it performs very well, but I won't be making a video until I receive an order of 4 brand new custom wheel hubs, as the current set have experienced some serious wear and tear over the past year thanks to my punishing tests

If you are new or aren't familiar with my previous projects, this chassis is powered by a near 12 volt battery and a 3rd party RC system that I made work with Lego motors. Multiple people have asked why I don't build bodywork for any of these large scale vehicles, and to be honest, I really enjoy building the chassis, while bodywork is...meh. I could get better with practice, but I simply don't want to spend time perfecting a body, and the extra weight would reduce the play factor, unless I become a wizard with flex axles

. I think this model is the ultimate balance of speed, moderate realism, and weight, (within my building style) so I don't see myself making anything new soon with my other hobbies and work taking up most of my time. Special thanks to nicjasno for the tips on the front suspension, and for making the LPEpower parts/show.

. I think this model is the ultimate balance of speed, moderate realism, and weight, (within my building style) so I don't see myself making anything new soon with my other hobbies and work taking up most of my time. Special thanks to nicjasno for the tips on the front suspension, and for making the LPEpower parts/show.

Feel free to leave any comments/criticisms/ideas for a new project. Enjoy!

-

I think he means 'there's room for improvement' :D For example with more panels and flex axles you could replicate the rest of the current indycar's aerodynamics, especially the wide body. Right now it just looks like a huge air brake :P Save up for some more white and red panels and you could make it happen!

-

I have used them and...didn't work for me. I guess in a portal hub it will fare better and I remember effe himself used them (correct me if I am wrong). The way I used it was different-power of two/four buggy motors in an independent suspension setup caused them to pop and eventually broke the thin hinges holding the center piece. I think the only way for u-joints to be strong at this scale would be if they were made of metal.

-

Great MOC, especially as a first. When I first saw this it reminded me of the Dejong MXR buggy:

-

A must have set, lots of potential for modifying/improving bodywork and color! Haven't bought an official set in a long time, looks like this is the one :)

-

In RC cars it seems that caster angle is greater than you would find in real life on models that take hard hits from extreme heights and speeds. As for a road car, work with whatever feels best. Advice? Make it strong and make sure the car doesn't bottom out easy, and don't put too much strain on weak parts. If it's a small car tilting the frame will require longer suspension travel to protect the bottom of the car. Some great examples are clarkdef's MOCs:

http://www.eurobricks.com/forum/index.php?showtopic=87118

http://www.eurobricks.com/forum/index.php?showtopic=97208

http://www.eurobricks.com/forum/index.php?showtopic=88753&st=25

And mine: http://www.eurobricks.com/forum/index.php?showtopic=88401

http://www.eurobricks.com/forum/index.php?showtopic=86913&st=250 (post 267)

-

I might just get the 42039 because of the potential for modification - we can make it into the beautiful endurance racer it deserves to be with flex axles and less jagged edges.

-

Some time has passed and I am currently working on the first version of this car (I'll revise it later to eliminate things such as chassis bending and excess weight). I took your advice the day you posted it and wow, it worked perfectly! Saved me a lot of time, and since then I completed the frame and started on the rear axle. I tried multiple setups which all had some underlying issues, but I think I came across a practical solution.

I had to raise the ball joint on the rack a half stud higher for the perfect angle, and as a final result the bump steer is practically zero.

I'm using efferman's 3D printed u-joints, hopefully they'll hold up.

I'm showing the possibilities and challenges in building a 'performance' car with this build, as well as gaining more experience for myself. I really hope this build will work out in the end, wish me luck!

-

I noted from your videos that the steering arm must be closest to the arm that is the same length, but this was a quick solution that was very strong. How do you suggest moving it down (on the hub) in a manner that will keep the strength? I'll be fiddling around with it for a while until it's perfect so thanks for the input :)

-

After researching some more reliable suspensions for the front axle I started working on my own design, which is a mix of inspiration from various builders. My goal was to have caster, unequal length arms, and as little bump steer as possible while still being very strong. At the moment I am trying to find a good way to place a large gear and a servo to match the rack placement.

The design is reinforced so there's little to no bend and it will stay together at high speed:

I got the bump-steer down to a few millimeters at most, and I think that's as good as it'll get with the plan I have in mind.

-

This looks awesome! Good luck with it, I'm liking the use of dampers and I hope the rear suspension holds up at full speed. Right now I'm torn between making a trophy truck, muscle car, or crawler with my 4 motors...

Nissan Skyline GT-R

in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Posted

Really great MOC! I agree it would be nice to see you make a 4WD drift car next or at least a test chassis and see how it handles, maybe get some nice long powerslides