-

Posts

68 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Everything posted by Nelson

-

@BrickBear Do you have any video of your whole model in action with all four legs going? I went back over this thread, made a reconstruction of parts of your leg design, and spent the evening studying it. I think we could combine some portions of your mechanism with mine. We are both using a rotating lever against a swinging lift-arm to raise the leg. The main difference is that you have a piece of linkage moving the leg back and forth while I am attempting to use the lifting lever to move the leg forward laterally in addition to raising it, and then using a slow-moving gear to move it back. The forward lateral movement part of my design is where I'm having challenges, so I'm going to try and incorporate your linkage idea instead. I think my cam design is still applicable in keeping the leg at the desired elevation while in its down position. I've also used springs to do this in a similar way to your model, and had success, but found the weight was too much after adding the bodywork. It may take me some time to figure out how to combine the two. I have the hinging "hip" point of the leg below the levers and linkage while you have it above. I have a "stay-cation" coming up and can dedicate some real time to this.

-

@BrickBear Have you done any more work on your design? I think I'm going to try to get a working version of my cam/lever design going even if it's not capable of moving the final aesthetic model. I just want to to prove to myself that the concept is viable at some scale/weight. I had an idea the other day that may be pertinent to both our designs. I think that one reason my version with the treaded cams "worked" (I use that description loosely) was because the cam contour was slightly off in a desirable way, just a bit out of round/flatter in a few key areas. I'm thinking that if I can get a version where the leg on the opposite corner of the leg lifting also gets the weight taken off it, it will balance much like a 2-and-2 leg version walker would. For example: when the left front leg lifts and moves forward, the rear right leg raises (not moving forward) just enough not to carry any real weight, but not enough to come out of contact with the ground. This would leave all the weight on the right front and left rear leg, balancing the walker, just like a 2-and-2 walking design. I think I can achieve this with a cam design that has two flat spots rather than just one. In my current version, the large flat area of the cam allows the leg to be lifted by a lever during it's step. But there could also be a much subtler/shallower flat area that acts to lessen the downward pressure during part of the cycle while the leg is on the ground and the opposite corner is lifting. Not sure if I'm explaining this very well. I'll upload some photos and video once I get some new parts in. Lego has release several parts in the past year that are allowing me to make more eccentric cam designs.

-

There is a difficult balance when trying to make a model like this. I could certainly make a lighter model that walks one leg at a time and looks vaguely like an AT-AT. Or I could make a very screen accurate model that has difficulty walking at all. If you haven't tried to walk that line, give it a go and see where you end up on that spectrum. It's a challenge you won't soon forget. @Oracid, I can only estimate what the final weight might be. The chassis and legs alone are 928 grams. I'd say the full model will end up somewhere close to 1.25-1.5kg. I've posted some photos where you can see the model with some studded beams in front to show length and width. I had a look at your walking models. Do any walk one leg at a time? @Mikdun, yes, the design is susceptible to binding up due to the weight resistance. It's not so much the power. The two large Power Functions motors have more than enough torque to snap the driveline axles. The parts themselves just don't cooperate. I can't get the perfect geometry for the various cams and levers and have to settle for something close. Ultimately, I don't think this current concept will work for the detail and weight of the model I hope to make. I've posted a photo of what I'd like the final AT-AT to look like. at-at-length by Nelson murray, on Flickr at-at-width by Nelson murray, on Flickr at_at_assembly_desktop_2 by Nelson murray, on Flickr

-

I think I’ve rung the final bell on this walking concept. It works at some level on lighter models, but just can’t handle the weight and torque at this scale. I’m pretty bummed because I’ve invested literally years of time in the design and it theoretically addresses all the engineering hurdles the challenge of a one-leg-at-a-time walker presents. It would likely work if I could use other materials than Lego. Back to the drawing board.

-

I ordered a couple large Powered Up motors and a controller/battery pack yesterday. Has anyone tried using their programmability to help conquer some of the challenges of the one-leg-at-a-time AT-AT? I'm starting to think I need to come at this with a totally new approach. I've come so close with my cam designs, even having limited success, but I'm hitting a wall on how much weight and torque that design can handle.

-

This is my first attempt at embedding Flickr photos, so we'll see how it goes. I've spent several days experimenting with variations on my design, but I keep coming back to the one in the previous video. I honestly don't know why that version "worked" and my new attempts using the same concept do not. I've been using a more stable cam, albeit smaller. The one on the left in the photo is the previous version. It frequently came apart and used a tread from the 1980s. Perhaps it was the give in the rubber that made it all work. I don't know. My latest incarnation seems close. Unfortunately, I had to order a couple more 5x7 liftarm parts, so I really can't test it properly. I'm concerned about weight. The legs and chassis are already .82 kilograms, and the even though this is the most solid chassis I've ever built, it still flexes under the weight and torque and depletes the lift of the legs significantly. It will probably weigh twice that once all the cladding is installed. old_and_new_cams by Nelson murray, on Flickr latest_failure by Nelson murray, on Flickr

-

Thanks for the share. I looked at some of these concepts on the 507 Mechanical Movements site (https://507movements.com/) My main issue with gear-based designs is that they are: A) not very stable B) have a lot of lash so the accuracy suffers C. can't take the torque applied to them in such a large and heavy model and tend to jump teeth. But I'm always open to ideas. That's why I'm here. If someone can make a gear-based design work, I'm all in for adopting it.

-

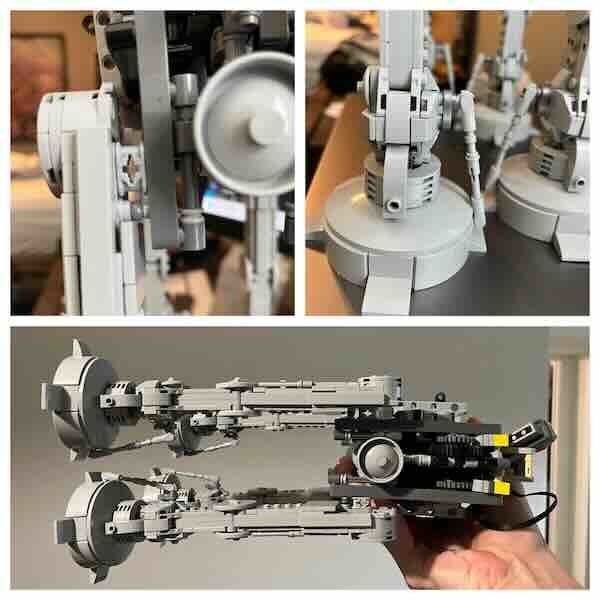

Here are a couple more ideas that may help your cause. I too have the same issues with balance/leaning and sought to get some compensation in the feet and legs. I came up with a way of mating the external legs to their internal connecting rods with a small ball/bar piece wedged in between a stud-pin and round 1x1 plate to create a bit of negative camber (Image 1). I also utilized the ankle strut feature seen in the film models to get more negative camber from the leg to the foot. I made the struts just a bit too long for the distance so they push the feet out a bit crooked (Image 2). Also note that the feet/ankles on my model have very limited movement, probably less than 10 degrees. I found this essential to keep the model from pitching forward or backward and falling on its face or butt if the feet slid. Finally, you can see in image 3 that the model is quite rigid at all points during its cycle. If I hold it sideways, the legs barely deflect at all. My early versions all started out pretty loose and I had to really lock things down. Of course, we are taking somewhat different approaches, which I find really intriguing, so these features may not be as necessary in your design. There was a post earlier in this thread that suggested a cam system that is very close to the concept I'm using (although I had already tried and failed with the parts he suggested and used a different method of creating cams.)

-

Glad to hear you're still keeping the project alive. As for the lower weight distribution, early on I decided to sling two Power Functions large motors underneath, at the bottom of the chassis, to both get the weightiest part as low as possible and also replicate the look of the film version engines. I also went with the small size battery box with super light lithium AAA batteries since in my design, that box ends up at the top inside the body. I've been tinkering with some new cam designs, but haven't had much luck. I'm going to try reverting to the build I had in the earlier post's video and see if I can refine from there. I have a few new ideas.

-

@BrickBear Did you get your AT-AT walking? It seems like things trailed off without resolution. If you’re on a path similar to mine, you got about 90% of the way there, then realized the final 10% was going to be brutally difficult. I’d love to team up on the challenge. I feel like I’m very close. As it’s been said: “With our combined strength, we could end this destructive conflict and bring order to the galaxy.”

-

Man. I have been itching to get in on this thread. The registration verification takes a long time for this site. I also have been trying to create a Lego AT-AT that walks one leg at a time for about 4 years. I have had varying degrees of success. This is my best effort to date. I'm intrigued by your use of gearing, quite advanced. I too started with the legs and worked inward, which ultimately was not the best direction in my case. I quickly realized that the chassis supplying the power was just as critical. Everything in my design has hinged on stability. Just as important as the motion of the lifting leg, is the rigidity of the non-lifting legs. This balance of letting components be free to move, then locking them down, has been incredibly challenging. I ended up going with more of a cam-based design than a gear-based design. Lego gears just have too much lash. When the legs aren't moving, they must be solid, and the gearing just allows too much movement. But I'm really excited to see if you can figure out a way to make it work. I feel like I'm so close, but the final issues are difficult to solve. https://www.youtube.com/shorts/uTedbcHywWU