-

Posts

44 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Everything posted by CharlesD

-

[MOC] GRUMBLER

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Thanks, i reckon that is the problem. I dabbled with an automatic gearbox in the past but could not get to work with high weight and torque. I might gvie that another try. -

[MOC] GRUMBLER

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

It took a while, but here it is; Video A bit disappointing, the car goes fast for a moment and then it just stops, after a minute it goes again. I am affraid the battery life of my buwizz 2.0's has depleted to much. I did manage to use a PU servo, but that has a tendency to not react in time, hence the crash. I removed two motors and supporting structure, managed to delete 350 grams for a total weight of 2KG, same result. Contrary to before the buwizz 2.0's lights do not go to red when driving anymore. Do you guys reckon the weight is too high? -

[MOC] GRUMBLER

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

You really went al the way, cool! I made a video to show how it performs; Video -

[MOC] GRUMBLER

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Wow thanks, i will try those hubs. I was trying to create something like the greyhound but faster which led to to motors needing to be internal and adding differentials, which led to the standard differentials not being strong enough which led to using the new differential and having to do a lot of upgearing because you can only drive the new differential with a 12 tooth gear in a normal 5x7 frame. Which then led to me using a 28 tooth gear to drive the differential which made everything wider and heavier. So to then to get the required thrust/weight ratio i had to add motors. My logic also being that the greyhound was about 1.4 kg with a gear ratio of 1:1, so to get a gear ratio of 1:1.66 with the same weight i have to add 50% more torque to get the same performance. I am not really into buggy motors, it kinda feels like cheating. Plus i have a bunch of L- and XL- motors laying around. Thanks, I tried a PU L motor as servo but it made really weird noises and did not want to cooperate fully with my buwizz 3.0, i can try again tough, maybe they did an update in the meantime. Weirdly enouh when using the buwizz template for the 42099 it did work allright. I have two buwizz 2.0 and one 3.0, the 2.0 are powering the rear L motors and the 3.0 powers the two front motors, that actually works quite well. -

[MOC] GRUMBLER

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Thanks, i wanted to make a video for a while but the weather got in the way. I honestly copied the greyhound's geometry, the steering links also have the same dimensions, only the pivot inside the model is further outwards to clear the drive axles. -

[MOC] GRUMBLER

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Thanks for the feedback. I use CADA metal U joints, they work excellent (except for intallation) I reckoned that the steering link starts at this point; Also the angle is needed to clear other components and achieve the required ackermann angle. Does the KPI angle need to be slanted relative to vertical? to create a Toe angle? Thanks, i updated the information. I used didumos wheel hubs because the standard wheel hubs have a lot of play in them, combined with the metal U joints they perform quite well. -

Hi, do you guys like this? 4x4 "drone" car with - "Adaptive Caster Angle" by virtue of shocks on roof. 5 - ~10 degrees - 6 L-motor drive, two front, three rear - three buwizz, option for fourth - independent suspension - Carbon fibre axles where needed - wheel hubs copied from didumos. - 28 tooth gear driving 28 tooth "new" differential - 1:1.66 gear ratio, roughly 15 KM/H Album

-

Axle Collection Thread

CharlesD replied to efferman's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi, After doing a lot of "research" i "designed" a front axle that i would like to share with you. The hubs and steering is copied from didumos's buggy. The goal from the outset was to have the buggy's off road performance but with a faster speed. I managed to integrate ackermann geometry and a castor angle (by tilting the whole assembly at 5 degrees) I used the new differential with a 28 tooth driving gear so as to not get any excessive up and down gearing in the drivetrain. The drive shaft splits to allow for the central placement of the servo. Two L motors front and 4 L motors in the back. It works pretty well, Although the steering rack catches on studs some times. The final model is still in progress. Any remarks or advice is greatly appreciated! The .io file is here https://bricksafe.com/pages/CharlesD/mark3-4x4 -

[MOC] 7 - 6 Mark 3

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

It has been a struggle to get the motors to all work on the same drive shaft and keep the gears from slipping. I think i finally have the most robust setup also in regards to the perpendiculair final drive to the tracks. Problem is that the weight keeps on increasing, to the point where i think the weight of two extra motors and support structure is not compensated fully by the increase in power. -

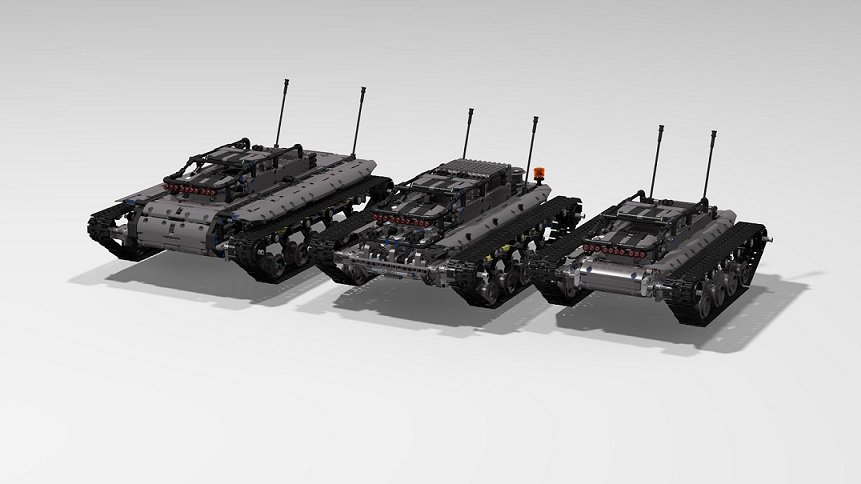

Hello, I would like to show you my project it has been a year and a half in the making and is functioning pretty well. - Christie suspension, spring loaded track tensioner - 6 XL motors, easily reconfigurable to 4 or 2 - 1:5 Gear ratio, 1070 RPM - 8 KM/h @ 12V / 730 RPM- 5.5 KM/h @ 9V - Gear ratio reconfigurable from 1:5 to 1:2.333 - 3 buwizz needed for ludicrous speed @ 1:5 - Two versions, 42065 inspired racing tank and "drone" shovel loader - Stud.io files are available in the bricksafe link Drives very good, the track tensioner keeps the tracks from throwing themselves off in corners most of the time. I have been trying to intgerate a gearbox but it gets too bulky or can not withstand the torque required. Any feedback or advice is appreciated!

-

Buwizz power limit

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi, Yes that would work, however i wanted to build something that was just stupid fast. I saw a video of a buwizz powered 42065 that did some drifting and that was what got my whole interest in technic tingling again early this year. And right now i am finally able to drift, albeit for a couple of minutes :) -

Buwizz power limit

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Are those the Cada L-motors that run at 1200 rpm? That is pretty much my experience too Yes, sorry, i stated that at the beginning, and i guess i am demanding more from the buwizz then it can deliver. That was for organizing and extension purposes. -

Buwizz power limit

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I shrunk it so i could post it here. I created a link to onedrive; https://1drv.ms/u/s!AsdRVifG8uuDhKogFIVDJUe3A8ZiQw?e=gIq5Gv I tried that but there was no performance gain, also the weight is a concern. If you want to extend your time than it is obviously a good idea, however mine never charge faster than .70 amps/hour. Considering the slow charging rate any powerbank would suffice. -

Buwizz power limit

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I have two buwizz, and i tried the same setup with 4 motors, but with the same result. I have a feeling that the tracks create a lot more resistance, it makes a hell of a noise. The chassis is pretty much fully enclosed so there is little cooling from airflow. -

Buwizz power limit

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Right, i thought that having 6 L motors on a 1.5 kg vehicle would be enough, would it work better if i add another buwizz? -

Buwizz power limit

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

After some testing with a laster thermometer i saw that the L motor cuts power at around 28 C on the casing. So i figured i need some cooling and i soldered two molex connector to a Power functions connector, and low and behold this monstrosity; I It works a bit longer but still gets to hot after about two minutes. Is this a problem that other people have seen? there is suprisingly little information to be found about overheating motors. -

Buwizz power limit

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

allright, thanks, will try that. -

Buwizz power limit

CharlesD replied to CharlesD's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

You mean that the led should stay on if the motor is not working anymore? -

Hi, I have designed a series of tracked vehicle using either 4 or 6 L or XL motors with two buwizz. And the problem i keep having is that after about 30 seconds to a minute the power to one side is shut off. If i then leave it to rest for a minute it will go again, but it will cut out sooner after that. The components to not heat up noticeably. I have experimented with different sizes and weights, and the problem is more noticable at higher speeds and weight. but weirdly enough it runs fine before the "limit" kicks in. I have cross connected the motors so it is not one buwizz that is at fault. Is there some sort of power limit i am reaching? Thanks in advance.