hoeij

Eurobricks Knights-

Posts

502 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Everything posted by hoeij

-

I bought two copies of the previous passenger train 7897, made them into one 5-car train and one 1-car train (after all, those "White Train Front 6 x 14 x 7 2/3" pieces had to go somewhere, right?). Each looks quite nice by the way, even that 1-car train is kind of neat (no other train that I have can go as fast through the curves without derailing, that battery box in a single-car train makes for a very low center of gravity). I was hoping to do the same with the new train, but now that I'm thinking about the cost, $129 multiplied by two, that's getting to be too much. I'm curious though, what can the motor comfortably pull? Can you attach 5 or 6 cars of similar weight and still get it to move even in the lower speed settings? Mark

-

Loved the review! By the way, I would definitely not recommend two motors in this train. If one of them starts to wear out, then the load you put on the other one, the one that is still good, becomes more than what it would have been if it were pulling the train all by itself. A much better solution is to make the train move more easily by "making the cut" (see the end of page 51 of railbricks #2). That's really the best way to make your motors last longer. My metroliner has one more car, but these 5 cars (with cuts in the wheelsets) is the same load on the motor as 3 cars without cuts.

-

MOD: Railjet highspeed train: My first train MOC project (still WIP)

hoeij replied to Odyssey's topic in LEGO Train Tech

That's a very nice looking train, no wonder you want to model it. It looks a lot like the new lego train 7938, which I'd love to have if it were priced a little lower. -

I think that at 3.5 years old he'll enjoy duplo trains better. Duplo's are also great to have when you have other kids coming to your house because kids of various ages can play with them together, you don't have to worry about pieces coming off the trains because since the pieces are so big, it'll be easy to find them again even if a lot of kids were actively playing.

-

I would use only one set, and simply make the wires longer. Cut the wire to one of the lights, strip the wire, insert some additional wire in between, and connect again. Make sure to connect in the right way because with LED light it matters which side is plus and which side is minus. Saves money and electricity.

-

I put a tiny amount of WD40 in the cylinders, that solved the locking problem. To make sure I wouldn't spill any, I just put a tiny amount of WD40 on the tip of a napkin and then touched the inside of the cylinders with that tip. In addition, I also use the 1x7 lift arms. At the moment it works well. I don't know yet how long this solution will work (but I'll find out in a few weeks from now at the train show). I'll let you know if it stops working (in which case I'll switch to the "make the cylinder longer" solution).

-

I have a few switches that either don't conduct electricity at all, or conduct not so well. I fixed them by adding wiring underneath. Also, some switches that haven't been used in a long time don't conduct electricity until I move the lever back and forth a number of times. But I've never seen a switch that sends the power to the wrong siding.

-

Just the locomotive? Then 10183 wins. It looks better the way it goes over the track. But if you put double-stack cars behind the BNSF, then it's better than 10183, mainly because it has better colors. The same is true for Santa Fe, if you run just the engine over the track it does not look good, but with the Santa Fe cars behind it, it looks awesome. Seeing it from a distance I'd say that BNSF + double stack cars looks better, from up close, the Santa Fe + cars wins. Without cars behind the loc's, the 10183 wins. By the way, someone mentioned that the Santa Fe cars are hard to pull: You have to treat the wheel sets (make a small cut in them with a Stanley knife so that the wheels don't rub the wheel holder, see page 51 of railbricks 2). That doubles the number of cars that you can pull. The wheel holder is a softer plastic, if your knife is sharp then making the cut should be easy and safe. Without the cuts, your Santa Fe is either going to be short, or stationary, or, something that burns out your motors very quickly. If you want to enjoy your motors for a long time, then you have to make the cuts.

-

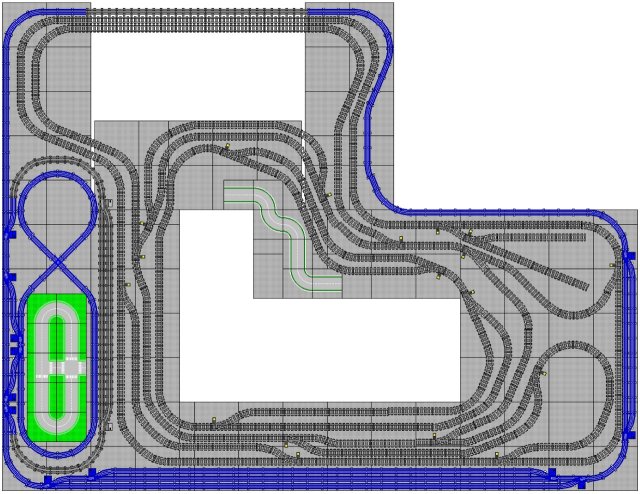

This will be at our local train show in Tallahassee, Florida (google; BBMRA). The switches that are not reachable from where I'm standing must be either remote controlled, or, the direction of the trains is such that the train exits the switch there instead of entering. The only remote-controlled switches that I have are 12V blue, therefore, the blue track must be on the outside while the 9V track is on the inside. One of the 9V switches (on the right-hand side) is unreachable from the middle, so this one switch determines the direction of the trains. The blue sidings at the bottom of the screen can park my cargo train (which is about 12 feet long) and two other trains (5 feet each). There are three more trains on the 12V track (4 to 5 feet each), all of which can park (this requires 10 interrupter rails, which I had to make myself because they are too expensive to buy on bricklink). This way all of the trains on the 12V track can be be started and stopped remotely. The 9V track does not need interrupter rails because the trains can be started/stopped with the switches. The inner most loop contains an Emerald night with about 8 coaches (from holiday train sets, some MOC, and a number of 10015). It also contains a 5-car train made from two sets 7897. Both can park and go. This line does not go over the bridge because the Emerald night is too wide to go over the bridge, and changing this 5-feet long bridge for just one train is too much work. The main part of the 9V track looks like two connected loops, but is actually a single loop (the trains turn around on the loops you see at the right hand size). There are 6 sidings, and I'll have 6 trains on this track. The sidings need to be quite long because all but one of the trains is 5 feet long, and you need some room for the train to stop. This one loop will run 3 trains simultaneously. The trains are made in such a way that their speeds are very close to each other, so it takes a while for one train to catch up to the one in front of it, but that's not a problem because there are sufficiently many sidings where I can pull over a train before they get too close. The main idea behind the design was this: No train should run for a long time without stopping (definitely not more than 5 minutes or so) and no train should stand still for a long time. The show is much more interesting if you keep starting/stopping different trains. And it is indeed very neat to see a train leave a train station, with a different train stopping there a little while later. You and I might think that the Santa Fe or the metroliner are the nicest trains, but what I learned from the previous year is that kids have quite a different taste (e.g. they'll ask to see the blue train (two 4561's) running). So never assume that because I think a train is less interesting than the others, that the kids will think likewise. That's why this year I set it up in such a way that everything can be made to start/stop with a press on a button or a switch (I really don't like the engine for 4561 so I made an MOC for that, it actually turned out quite nicely). The main 9V loop will be powered by three 9V controllers, the speed setting is #4 which is about 7.5 volts (one controller is not enough because with 3 trains running the voltage will drop). So the speed setting on the 9V track is always the same. I have a remote controlled AC outlet, and everything is connected to that. I keep the remote control of that (its a small device) in my hand at all times. This way, if a kid puts their hand on the track, or, if I make a mistake with the switches and a collision is coming, then I can shut down everything (except the battery trains, that's why they *must* be on a separate track!) with one click. This is important because the tracks are right on the edge of the tables, and the floor is concrete. This approach worked really well last year, whenever disaster is imminent, the solution is always the same button. I meant: 6.5 volts.

-

Here is my layout for the local train show a few weeks from now. Buildings are not shown. The gray base plates are not actually there, they only function to show where the tables are (five 8x2.5 feet tables, four 6x2.5 feet tables). The missing gray plates at the top is a 6 feet long bridge.

-

That table will fit a loop with 16 curve pieces and 10 straight (5 on each side) pieces of track. The straight pieces will be close the the edge, but that's OK. In the length, you'll have a bit more space left. If you want to use the table to the max, you can have 5 + 3/4 straight pieces on each side (the flex track has 1/4 length each). One straight track is 16 studs, which is 12.8 cm. Mark

-

I have nearly all the 9V train sets, and some 12V sets too. My vote goes to 10183 hobby train. It's got everything: passenger cars, cargo, locomotives, etc. It can be a bit of a puzzle to make as many as possible train cars out of a limited number of copies of 10183, some changes are needed, sometimes large changes, but the end result is very nice.

-

12V Conversion of Emerald Night 10194

hoeij replied to LEGO Train 12 Volts's topic in LEGO Train Tech

I don't think that adding a resistor is a good idea. What it will do is slow down the train drastically in the curves, but slow it down very little on the straights (in curves the train draws a lot more current than it does on the straights). That makes it more difficult to control the speed of the train. Just run it without a resistor, and simply don't run it too fast. Mark One more thing, why not simply connect a 9V controller to the track? This seems so much simpler than converting 12 to 9. Moreover, it will also run better that way (less slowdown in curves) because the 9V power supply is regulated and the 12V power supply is not (at least, the one I have from the blue area, the voltage at the power supply decreases noticeably when the train goes through a curve). Even with a 9V power supply, the train will of course still slow down in the curves, but not as much as with the old 12V power supply. Mark -

If the tracks are lined up right next to each other (since the sleepers stick out 1 stud, that means 2 studs of space between the rails) then you do get collisions, but if you keep 1 more stud of room between the tracks, then all of the standard 6-wide lego trains work OK (I've used this with many standard lego trains, no guarantees for MOC's of course!). Note though that with trains that have handle bars sticking out, when they pass each other in a curve we're talking about one mm of clearance. It does look kind of scary especially when moving in opposite directions. That 1 stud of empty space between the tracks is not enough for the Emerald night, which is wider than 6 studs, which means that I don't let it run over my train bridge in order to prevent collisions with other trains (it doesn't collide on the bridge itself, but on the curve that comes after it. But the width of my bridge does not allow me to put more than 1 stud between the tracks there). You can my layout for our local train show here: www.math.fsu.edu/~hoeij/t Mark

-

This would require some track modification, otherwise it takes too much force to move the lever. I do think track modification is the best way to go though. You can find it on the web how to do it. If you have two remote controlled switches near one another, you could save on wiring by powering them with batteries and using the IR remote controlled power functions.

-

I'm curious to know the setup of the tables, how to organize them so that there is room between them to reach things. Mark

-

I would buy regular tables and use those. In the US, the most cost effective solution I have found is to use 6 by 2.5 feet folding tables at Costco for $49 each. I would prefer to have 8 feet long tables but they cost a good bit more (if anyone knows where to get them at low cost, let me know).

-

In essence, the length of the train is not a good measure for the load on the motor(s). The load on the motor(s) is roughly proportional to the weight of the train (if the wheel holders are good, more on that later). A 6-car long 4511 (front engine, 4 middle cars, and back engine) is exactly 5 feet (note: this train looks much better moving than standing still). This train is a fairly reasonable load for a 9V motor, I estimate that the average load is well below 300mA, though I admit that I have not measured that for this train. A 4-car Santa Fe train (one engine plus 3 cars) is quite a bit shorter, but it is a heavier load for the motor because the cars weigh much more. I bought most of my trains used because I started only a few years ago, and I've noticed that the heavier trains like Santa Fe all had wheel sets that had a lot of friction. Page 51 in railbricks_2.pdf explains why this is so, you have to make cuts to the wheel holder, if you don't, then after a while, the wheels do not quite fit anymore and start rubbing against the wheel holder, and this happens sooner on the heavier train cars. Before I made the cuts described on page 51, this 4-car Santa Fe was a very heavy load for one 9V motor, but with the cuts, the load on the motor is cut in half (which means that the motor will last *much* longer. The reason I started looking into this is when one of my motors died). With the treatment, it seems to me that the load is pretty much proportional to the weight (the length, the number of wheels, the number of cars, etc, does not seem to matter much). Without the treatment, the load on the motors can be very much higher, and just keeps going up the longer you run the untreated wheel sets. Some of the 8 wide trains I've seen on the internet are really awesome, but this comes at a great price: If I build even one of them and bring it to the train show, then all my 6 wide trains will no longer look proportional, they'd all have to be made 8 wide. Or, one would need a separate display for the 6 wide, and one for the 8 wide (I'm doing a lego layout at our local train show all by myself, so that's not doable). By the way, although I'll bring the charger to the train show, I think that the rechargeable battery 8878 will hold up for the whole day because no train in the layout will be always running, and no train will always stand still. The show is about 6 hours, and the battery lasts about 3 hours, so the Emerald Night can run half of the time, or maybe a little bit less because it is pulling an 8 feet train.

-

Yes, it looks identical to the lego motor (item 590). The parts in the case that take the electricity from the wheels to the connector are still in there, only the motor has been removed so that it can move over the track with little effort. I listed the item in my bricklink store: TLHBricks, username mhoeij. Do you need side-rails too? (item 2871). If so, I can list two of them on my bricklink store for $1 each.

-

'956 - Auto Chassis'

hoeij replied to underwurlde's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I remember as a kid I spent endless hours trying to build the Jeep. And I also remember thinking: if just 1 drawing is enough to build a Jeep, then 0 drawings should be enough too! Building MOC's seems obvious in retrospect but at the time it was an eye opener and really sparked my interest in spending long hours designing a car, building it, playing only 10 minutes with it and taking it apart to design a better one. Anyways, thanks for bringing up memories of the best Xmas gift ever! -

300mA is already a fairly heavy load for the 9V train motors, that's enough to pull a 5 feet long train. AAA batteries can produce 5 times as much. So the limits in pulling power don't come from the batteries, the limits come from the traction and/or the motors. Of course, the smaller the batteries are, the sooner they'll run empty, that's clear. But 6 AAA batteries can produce the amps needed to pull a long train.

-

I could put it in my bricklink store. To make it fit in the tender, you'd have to make the tender larger, make an opening in it in the bottom, and you'll need a LEGO® Power Functions Extension Wire (Item #: 8886) because one end fits on the "9V motor without motor" while the other end fits on the XL motor. I'll try it out to see if it works OK. I've been thinking about the long term future of the 9V system. The track and the controllers basically last forever. But the motors don't. I think that this means that in the long run, the 9V track and controllers won't go up in price, but the motors will. Many 9V motors can be fixed at low cost (DC motors are cheap). I don't have to start repairing for some time because I have a good number of spare motors, but I think that eventually that will have to happen. Maybe there should be a category on bricklink where people can sell motors that are either dead or near dead, so that others can repair them (or use them for other purposes like taking electricity of the track for the EN).

-

I took a dead 9V train motor, opened it up, and removed the electrical DC motor that's inside it. I also attached some wiring to this "9V train motor without motor". That could be put in the tender, and then run the wire to the XL motor in the EN. This way you can run the EN with the usual 9V controller. I do prefer the usual 9V controller over the RC one because it is easier to quickly select the desired speed setting. By the way, the DC motor in the 9V train motor is I think quite el cheapo, and I've been considering replacing them in some of my other near-dead 9V motors. But I don't know yet where to get the right dual-axes DC motors that fit in the housing. If anyone is interested in buying a "9V motor without motor", I'm not using it at the moment. Mark

-

With my EN I'm using the O rings only on the rear driver wheels (both of them). It reduces friction in the corners significantly and the traction is still very large because there is more weight on the rear wheels since that's where the motor is. But the main reason for removing the O rings in the front is that it makes the EN run less bumpy. My 9V track is all bought used, and some of it has some minor bumps on it. Without the O rings in the front, it runs quite a bit smoother on the lower-quality portions of the track. My EN is pulling an 8-feet long passenger train without any difficulty, so it has plenty of pull. But how to get to the uphill part without stalling at the bottom, I don't see any simple way to do that. I think you're looking at major modifications to the underside of the train to make room for the front truck to be able to go up and down. Same problem in the back. I'd love to hear a solution if you have one (if so, I may consider widening my train bridge, which at the moment is not wide enough for the EN to pass through...). I don't like the idea of pushing the EN with 9V motor(s). First of all, an engine is supposed to pull, not be pushed, but also, the gearing of the 9V motors is not good for the EN, too much speed and not enough force, it's really too much of a burden for one 9V motor. It's better to use the power-functions stuff (yes, the rechargeable battery and the rest of the power functions stuff is very expensive, but you can re-use it to make the old 857 technic motorcycle remote controlled, and that's worth something too).