DadScientist

Eurobricks New Members-

Posts

8 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Everything posted by DadScientist

-

I can’t say that I’m bored. :-) It is funny looking at the chassis. It takes a second to realize there’s no motor strapped to it, and then I have to check again… I know the motors are in the wheels, but it still doesn’t look right. How fast did it go? I can say that I’ve been waiting for some downtime to play with transmitter programming and learn more about sensored motors. I feel like there’s a torque/ acceleration limit, and probably an RPM/ speed limit… but controlling the motors is the obvious gateway to slower acceleration and a higher top speed. Thanks for the kind comments on the Substack. Having built a few versions of the buggy, I have plenty more to say. It was a fun experience to figure out what you’d done. Cheers! James

-

Oh, hi! That's good to know, thanks! I'll definitely look into Quicrun. Life has gotten busier lately, so I've had less time to really dig into the buggies. I've built two or three versions so far, and I'm slowly spinning my notes into more posts over on Substack. (The latest entry is here) I also gave a solid try at making your 42124/ outrunner motor project come together. I got really close to getting it dialed in, but then had to put it to one side. I'm slow-rolling the posts, and trying to maintain a weekly schedule. That way I can maintain it as an active project, while I wait for more headspace to get back to the experiments I have on deck. Hopefully those schedules line up, and there's no gap in the schedule. Back in March, you'd posted this: "Current status, after all the LEGO prototyping, constructed a very competitive 1:10 on road race car, driven by 4x 1300kV in-wheel motors, controlled by an ESP32 and a 4in1 BLHeli-s ESC (not an AM32). Waiting for a test by world's #8 ranked RC-driver ;) If any interest happy to post about it." Is that the same car you just put up? How did that test go, if it's happened? (Curious to hear about your other exploits.)

-

OK, I have an electronics question for the audience, because I'm better with Lego than I am with R/C... so far. I spent a fair amount of time playing around with janssnet's brushless buggy from YouTube. And I've been trying really hard to figure out what he's using for an ESC. The motor's only a 2838, but the ESC still looks really small... it almost looks receiver-sized. (see screen grab below) Compared to the ESCs that came with my motors, it looks really tiny. I almost started to think it was a drone ESC. (I bought one to try in this application, but haven't tried using it yet.) And ultimately I started to wonder if that's how he managed to not snap off his Lego U-joints: Maybe he's using an undersized ESC, and not running the motor at full power? The video's 4 years old, I'm sure there are some things he's forgotten. But, my question is: Is it actually ok to run an under-powered ESC for a brushless motor? Do you run the risk of overheating the ESC, or just slowing the motor down?

-

Another random discovery… Apparently bearings are easier to mount than I thought. I was screwing around with the big ball joints, and realized they could be pinched this way. ANd I'd just figured out earlier that a bionicle ball-socket fork would hold a bearing. So... I tried this. Works pretty well, without needing to drill or melt anything. I still like Knott's melt-in idea, but this might be worth playing with.

-

I'm not 100 % convinced that you can't use a stock lego portal axle, with bearings. I was looking at some new ones that I just got in the mail the other day, and it looks like the hole where the spindle goes in is ~ 3/8". R166-ZZ is 3/8 OD, and 3/16 ID, and you can even get em in ceramic. So that might just be the ticket. You might want a bearing on the back side, too, which would be another adventure, maybe use your pull-in technique on that. Or, use a module bush, with a cross block fork at either end, and clip that onto the back of the hub where the wheel axle goes. I'm sure there's enough plastic in the module bush to drill and melt in a bearing. That subassembly would simply replace one of your 3M half-beams. But it's possible that 3d printing a tapered ring to backfill the portal and hold the bearing would be enough. Or, you know... baking soda and superglue. Portal axles are only 85 cents per piece. You have to wait forever, what with int'l shipping to USA, but it's not going to be an expensive experiment. Order 50 of em, and have at it. So... You might be closer to nailing this than you think. Where are you? Other ideas... Maybe chop the bell off of the portal hub, and mount one of these with two of these to sandwich it? I haven't measured, but maybe the large diameter of the bell will hold a skateboard wheel bearing. Who knows? Of course, you could also try try roller hubs, or planetary hubs. (Lego's nomenclature cracks me up. If planetary hubs are "WHEEL HUB, NO 4," and roller hubs are "HUB, NO 21," then where the hell are all the others?)

-

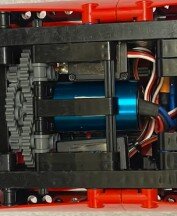

@Knott a.) I was looking at your twisted axle from April... that's impressive! One suggestion I thought of was to use the metal U-joints from Metal Technic Parts: Their design is basically just round-hole with set screw, which might allow you to just use plain round metal stock, as long as you file a notch for the set screw. Could be aluminum, steel, Ti, whatever... But it looks like you have the axle problem (potentially) licked. b) Wanted to say thanks for the tip about heating up a bearing and pressing it in. I was trying to wrap my mind around using a precision reamer, or something like that. This is much better: No plastic removed, no strength lost. What kind of aluminum rod did you use? Just 3/16" rod, or something else? Any other advice for keeping the bearing centered in the hole while you squish it in? --- Other than all of the above, just wanted to say hi to the community, and say thanks for sharing everything in here! So much good information... I'll try not to gush. This time. I've been trying to figure some of this out for months. I haven't touched RC cars in years, (pretty sure it was 1988) so a lot of the brushless motor stuff was all new to me. (like kv ratings...) And I'm now starting to appreciate some of the options with the transmitters now, too, like adjusting throttle-up curves. I have so much to learn... I started with building a copy of @janssnet's brushless buggy from youtube. It was a long, drawn out process, with a dozen screenshots printed out for reference, and occasionally loading up youtube on the TV, so I could get a better view of what was going on. All of the black framing looks so cool... and it's so hard to see contrast. But eventually, I got there. I made a few modifications: This version is longer than his, because I the motor came with a 35A car ESC, instead of the small drone ESC he used, so I needed room to mount it. I used planetary wheel hubs, because I was worried the torque from my oversize tires would torque the axles too hard. (I've since tried straight up, axle to wheel... my instincts were right.) I had to modify the front suspension to use Lego's roller hubs, which are taller than the steering hub @janssnet used in most of the builds I found on youtube. I also had a simpler rear suspension, becuase (at the time) I didn't have the big turntable. Lastly, I did something different on the back of the front suspension that required the longer stop axles. But holy cow, the amount I've learned from following all of the bread crumbs in his videos. I'm incredibly grateful. It hasn't been easy. And I think for newcomers I'd probably recommend just going with the Zene motor. (I haven't bought one yet, but I think I will. But having seen @Knott's twisted aluminum axles, I'll stick with using just the one. ;) ) I built a second version, shorter, with a 2838, and yellow technic beams, and black panels. So far, it's had more luck, but it's been taken apart so many times, the pegs are starting to loosen. I just rebuilt it, and got the drone ESC that I'm pretty sure he used, so that'll go back together soon. I also just built his version of the 42124 buggy, to take a break from that one. But I built it with a 2838 motor, instead of an outrunner. So far I'm busily stripping 8T gears, because I haven't figured out how to lock the motor in solidly enough. A little vibration throws the end of the motor around, and then the gears don't line up as well as they ought to. I've learned a lot in this process so far... Use silicone, not lithium grease... And DEFINITELY pay attention to motor kv rating.... "But that 2430 motor is SO DINKY! How could it possibly WHOOOOOAAAAA.... " (7200 kv. When I bought it, the concept of kv was something I didn't understand yet.) And on and on. A lot of busted parts. Axles welded into holes, melted and snapped, and beams that either welded themselves to the axles... or dissolved, (thanks lithium grease!) deposited themselves around the axle, and were left with a big, wallowed out conical hole. One of my favorites so far was the melted homemade pinion. (below) Literally melted down through the clearance hole, into the motor casing. I still hadn't figured out how to mount a pinion to a 2mm hole, other than drilling an axle. (See also, "7200kv") Note the melted plastic around the hole... and the melted half bushings that were meant to help keep the axle in one piece... and the drip of axle plastic, coming from between the pinion and the bushings. For now, future experiments will involve bronze bushings, ball bearings, and drilling a 2M aluminum axle to fit onto that 7200 kv 2430. Maybe if I can learn enough about changing the input curves, add enough ball bearings, and perform some sort of ritual sacrifice to the gods of speed, I can tame that little beast and make something that really cooks.... and hopefully for more than a minute. (Then I'll try very hard not to mount it into that Mario Kart kit, and crash it into the Lego store at the mall.)

-

Hi All! Sorry for the lag, it's been a crazy couple of months. I'm close to Boston. I'm not up on a lot of the older stuff, or the modern stuff, yet. It's all in process. Most of my projects have involved mounting brushless motors, without blowing up the build. I've had mixed success, but ongoing progress. So, that's exciting. I'll dig into some of those resources, thanks all!

-

Hi all, As I struggle with running bigger motors/ more 'stuff,' I hit upon the idea of using some of the older battery boxes that hold 3 'C' cells. I can tie two of them together in series, get the 9V that I need, and it should theoretically last a lot longer than the AAs that I've been stuck with. As it happens, I also have an old 9750 set. Long story, but it has the blue plastic case, with all of the wires, some of which are even color coded. (Grey, obviously, as well as red, yellow, and blue.) All of the parts are present and accounted for... light bricks and their holders, optical sensor and encoder wheel, touch sensors, etc. Instructions are basically untouched. And, I have the old interface A, and the circuit board that used to get shoved into an Apple IIe. (I think it was a IIe, I could be wrong.) And I figured, if I was going to go with all the vintage battery boxes, that the vintage interface might fit right in. BUT, I don't have a IIe handy, and don't really want to turn this into a deep dive into computing from my childhood. So, I was wondering if there were any contemporary solutions for driving the thing with a more modern computer. This would mean cracking open the shrink wrap on the electronic part of the set, which I haven't been able to bring myself to do. I can't even break up the box with the parts... I don't need any of them desperately enough to feel ok about separating any of it, unless/ until I can think of a good use for them. But as I start to get deeper into the robotics stuff, it might be a cool option to have. Especially if it can handle powering higher-load motors and such without getting fried.