Search the Community

Showing results for tags 'pneumatic'.

Found 155 results

-

[MOC] Some air pumps

NotANumber posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Probably already done to death, but meh: pneumatics are cool. Here are two air pumps I keep on my shelf for boosting some of my models. The focus is on compact and minimal but also functional design. The first is for first-generation, single-ported pneumatics. It's just a small cylinder connected to a geared 9V motor with a pair of wheels as a crank. Next up, one for the dual-ported system. This one has two blue pumps set 180 degrees apart to smooth the airflow, driven 1:1 through 16-tooth gears by a PF XL motor.- 7 replies

-

- compressor

- pump

-

(and 2 more)

Tagged with:

-

Lego Pneumatic Engine

LegoEmbodiment posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

https://youtu.be/UFPNWZeeXQw Lego Pneumatic Engine. What is it? How to make it? The first it needs to finish Lego fake cylinder like in this video https://youtu.be/HcHneyewATE or https://youtu.be/0aZvWva41Ek. The second - to add o-ring to Lego piston like in this video https://youtu.be/wZu-l32Dajw or . -

New pneumatic valve and modified pump

jrx posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Yesterday I got my 42080 and of course at first I had to test the new Pneumatic parts. Beside the new valves there's a modified pump 6L in the box. It seems it is so new that it isn't printed on the box :) The modification of the pump is just the outside. Function is still the same. But more important: The new valves. My hope to get a valve with continuously usable lever is broken. The new valve acts mostly like the older ones. Bad news for using with Servo motor: The level goes only 45 Degree in both directions. But, and that is new, it seems to me that there is a new position between "on" and "off" on which the valve throttles the airflow. Maybe someone can test and confirm this. That's all so far. I also made a video showing the new valve in detail. -

After seeing @jwarner's excellent smalle crane and @Ludo Visser's WIP on a good looking undercarrage, I kept being reminded I still had one of these on my "to-do list". It's the last (I think) in what turned out to be a series for me of small versions of vehicles that are usally the big 4 "flagships" in Technic that return every couple of years. It features: - Boom lift by pneumatic cylinder - 1 stage boom extension - Rope (with old school 90's lock and also a hook from the 90's ) - 3 axle steering with different steering angle for the front wheels (bottom 12T bevel gear at the rear) - Working V4 (allthough a little out of sync, can fix that as soon as Lego actually makes parts to shift direction at this scale on 1 stud instead of 2 ) - Cabin tilt on the superstructure (through a worm gear controlled by 12T bevel on top) - Superstructure rotation (top 12T bevel gear at the back) - Outriggers (couldn't fit a central operating method so they are moved at the rear through the LBG crank shaft parts usually used for fake engines) Stuff I couldn't squeeze in no matter how hard I wanted to: - 2 stage boom extension (with 11L thin pneumatic cylinder). I tried, but with ropes in play I was looking at a 2 studs wide crane without a shell to give it ridigity, anything with 3 and 4 studs in width with the shell still felt very flimsy. And shortly after switching to a 1 stage boom with these 11x3 panels I really started to like that clean look on the crane vs the thin liftarm extravaganza I had in play earlier - A diff (or at least have the fake engine run in some form on both non-steering wheels). I barely managed to get 1 wheel driven. Had to use some ancient 90's Space Shuttle technique with a rubber band to get the stuff routed. I considered a blue clutch gear from the Chiron on the steering shaft, but besides that really killing my ground clearance it wouldn't fit up top thanks to the pneumatic cylinder. Why not leave the feature out? Can't do that when all the other mini's I made had fake engines. It was this or never getting finished pretty much - And as mentioned earlier: the outriggers being controlled by 1 knob. Couldn't route it to the rear, already crowded, the cabin in the front was blocked by steering angle of front wheels and crane up top. I am happy though that they at least can lock into place and lift the whole vehicle. And a couple of more images: Instead of messing with the length of the hubs on the 2 rear steering axles to get different steering angles, I shortened the front steering hubs by 1 stud to get a sharper angle with space lost in height (rear of the driver's cabin) but not in length. It's turning radius is pretty sweet, very small. Tried to get some details in the cabin, but they are missing half of their bottom seats thanks to the steering wheels. Also messed around a little with options to get the outriggers folded into the body as much as possible, not sticking out more than 1 stud up top and when extended looking at a decent angle. Hmmm, now that I am looking at this picture, perhaps I should swap the 4L thin levers for LBG or something to make the fake engine "pop" from the black chassis. Anywho, thanks for watching and reading.

- 10 replies

-

- mobile crane

- pneumatic

-

(and 3 more)

Tagged with:

-

I have been working on this project for what seems like forever. I'm happy to have it done. The full gallery can be found here. Much more at thirdwigg.com. Full Lift With TLG Balloon Tires Chassis

- 34 replies

-

- pneumatic

- end loader

-

(and 2 more)

Tagged with:

-

42080 Forest Harvester

Ngoc Nguyen posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

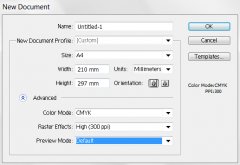

Time for a dedicated topic as well. Link for high res image: https://mega.nz/#!qDQh2aZC!9L0SMGXuq9L_1oSgaaj20bn-H47tcH2jS8gCeEgJlFM This is the ultimate color barf that TLG has managed to produce: - Lime - Green - White - Yellow - Black - DBG - Red - Blue - Medium Azure - Reddish Brown Discoveries: - If you zoom into the cabin you can see a water bottle with a silver cap - There is a 6L towball link bar under the front row of wheels.- 313 replies

-

- pneumatic

- forest harvester

-

(and 1 more)

Tagged with:

-

[HELP] EV3 and Pneumatics

bluatigro posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

how do i steer pneumatics whit ev3 ? -

Smoothing pneumatic cylinder operations

Omikron posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hello there! I ran into a small problem recently. I'm trying to synchronize a couple of pneumatic cylinders which are not connected directly to the same frame and they keep extend and retract at different speeds. The hoses are exactly the same length and the cylinders are from the same batch - they are not old+new. But even if I get the synchronization correctly then one of the cylinders does a harsh or abrupt action. For example when the pressure in the system is rising one cylinder starts to operate right away and the second cylinder is "stuck" until the pressure is high enough and it extends abruptly. I've spent couple of hours manually extending and retracting cylinders in order to make them work smoothly without success. Did you have such problem and if so - what was your solution? -

Hi everyone! Not long ago I finished my latest MOC. And today I finished the corresponding video. So it's time to show it here. Shortest description would be: Stewart platform for Ideas set 21306 „Yellow Submarine“. The longer description is: It's a MOC I built around the Ideas set. It's a fully working stewart platform powered by two pump compressor and controlled by two joysticks. Everything is working pure mechanically and with pneumatic. For better look I used system bricks for the control tower (with female naval engineer) and the housing of compressor and control center. Components: 1x PF L motor 1x PF M motor 1x PF LiPo 2x PF switches 6x Pneumatic V2 cylinder (small thin) 2x Pneumatic V2 pumps 6x Pneumatic Valves some PF cables Looking forward to reading your comments. Best jrx

-

Pneumatic hose maximum length

cptkent posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi, Can someone please tell me if there is a practical maximum hose length for a Lego pneumatic system? The application I have in mind is for ‘remote switching’ of a railway track point. The track point is ~1500mm from where I want the switch. I presume I would be best to use 3rd party hose at these lengths. I’ve tried to search for an answer, but nothing has turned up. Can anybody here help? thanks david edit: ps, I am probably going electrical, but just thought I’d consider a pneumatic solution, though it appears in any case parts for that may be difficult to source. -

[MOC] Manitou TMT 25S

Minique85 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi everyone, For the past year, I have been working on this MOC, making very slow progress mostly due to a lack of time. About a month ago, I finally reached the point where I considered it finished. It's not perfect and many things can be improved, but I am happy with the current state. Enough to finally make some pictures and a video. The MOC is based on the Manitou TMT 25S. It is a hydraulic forklift, one that hooks on back of trucks, but uses an unusual design. A picture from the original: It also combines some interesting hydraulic functions which I tried to carry over to my model. In the end, this is the list of functions I managed to implement: Manual steering, control placed at the back, behind the cabin - rear wheel goes 360 degree. Pneumatic compressor using an M motor and two pumps Electric switch to control the compressor Pneumatic functions for: Boom elevation Boom Extension Fork control Front outriggers Boom lateral adjustment Initially, my intent was to have an auto switch for the compressor. However, after many trials, I could not calibrate it properly so that enough pressure remained in the circuit to control all functions properly. The switch would not always return in position when the pressure was dropping, making some functions such as raising the boom unusable. So I replaced the assembly with a manual switch which can easily be controlled when air is required. To smooth out the functions, I used an air tank which is hidden below the control valves in the back. Overall, the functions are working well. The main issue is the control of the fork, which really needs better smoother valves to have finer control. Also, since it is pneumatic, It does not maintain its position when elevating or lowering the boom. I could not find a way to do that while keeping the boom extension which is required. So here are the video and pictures. I hope you enjoy it. More pictures are visible on the BrickSafe folder: https://bricksafe.com/pages/Minique85/manitou-tmt-25s -

[MOC] Ultimate Volvo EW160E - instructions done

Ivan_M posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

EDIT: Finished pictures and video: Finished model Finished model Finished model Finished model Finished model Finished model 42053 is very nice set but I cannot justify buying it when I have all the necessary parts in my collection. In the end I tend to be dissapointed by the official sets due to my overexpectations. So I decided to build by own Volvo wheeled excavator. As usually I build in scale to blueprints, this time the setter wasn't wheels as usually, but length of the main cylinders. This is primary to achieve the best movement range of the arm. In the end the wheels 49,5mm fit precisely and the scale is (my usual) 21,5:1. Width is 15 studs like in the set, wheelbase is 15 studs as opposed to 17 studs in set. I want it to have 7 pneumatic features: 1) bucket emptying 2) arm movement 3) + 4) two piece boom 5) cabin lift 6) front blade 7) rear outridges Additional features: 8) front pendular axle, steered by HOG 9) superstructure rotation by knob I started with the arm and 2-piece boom. The bucket is by far the biggest drawback of the build with its poor shape and mounting points. I have considered other buckets (I have all TLG produced) but this is the best out of bad. Maybe I will try to build better one from bricks in the end. Everything in real machine is very thin when translated to my scale so the arm is build from technic bricks, arm is 1 stud wide with some plating on sides for looks. The two section boom was quite a challenge due to width. I started with dual thin cylinders at the base but they struggled to lift the boom when it was in full reach. The whole boom had to fit within 5 studs so the first section is actually 2 studs wide and second section is 3 studs wide. Fortunatelly it is not very visible because it is covered by cylinders. The arm movement range is very similar to real machine, the only angle that is smaller is between booms due to the length of the old pneumatic cylinder. The next step was undercarringe. This was quite difficult as well, mostly rear outridges. The range of movement for small cylinders is very low and it had to fit in very little space. The reach is not perfect but it is acceptable. They are weak as kitten of course, fron blade as well, but I wanted them operated with pneumatics. There is also drawball connector to mount trailer behind the excavator. The front wheels use my usual setup with small hubs for great turning radius and ackerman geometry. The disadvantage in this case is that the wheels are mounted "wrong" way, with the shallow part facing outwards as opposed to rear. I can live with that however, I just cannot build without ackerman anymore. Last thing I have is the cabin. It is also 6 studs wide as in the set and it is quite similar to that one but more detailed. I have added brick build front lights and some greeblings. The roof is supposed to be yellow of course, I don't have the bricks yet. I'm now working on body. WIP - Arm reach WIP Arm folded WIP - Arm reach upper WIP - Arm reach lower WIP - Cabin WIP - Cabin -

[Idea] Link Two V2 Pneumatic Actuators End to End.

Saberwing40k posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

So, @Fieldtest requested a device to link two of the large V2 pneumatic actuators together, end to end. this is what I came up with, and it is so potentially helpful that I thought it would be worth sharing in its own topic. Pneumatic Cylinder Connection by Saberwing007, on Flickr It's pretty easy to make, but it was a real pain to figure out, because Lego, in their infinite wisdom, made some of the dimensions not a whole number of studs, which is really odd for them. Thus, this build needed some very illegal connections in order to work and be stiff. I've also got some more construction pics: Step 01 by Saberwing007, on Flickr IMG_20171214_180212047 by Saberwing007, on Flickr Step 03 by Saberwing007, on Flickr There you go, I hope you all find this to be useful. -

Need Help Replicating Historic Engine System

GeorgeCrecy posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Dear fellow LEGO enthusiasts, I am in dire need of some help from you folks who are definitely more knowledgeable than I. In this case, I am needing help with the replication of the RMS Titanic's Reciprocating Engines and Turbine. I am in the midst at the moment of working on the project below, though I have not updated it in a great while due to university work. See this link here for the project thread. But this is a minifig scale project, with every door, every window accounted for. This means that in regards to the engines, I am also seeking to make them at least somewhat true to scale and able to work as intended. Obviously this is a big job of some top notch Edwardian-era engineering, but I am hoping that there might be some out there not as technically-challenged (pun totally intended) as I am, willing to help me get this part of the project off the ground. Some of the features I I am looking for include a fully air-powered system, where the air supply would come from tanks hidden in the mock-boilers, that are then funneled at somewhat high pressure to the Triple Recip. Engines, which means that the pressure would go down as it goes through each cylinder (HP, IP, then two LPs). The leftover air at a much lower pressure then goes to a junction that can either go to the Parson's Turbine at what was historically 4 psi, or can go directly to the condensers. With the latter I intend just to make the outside of it and hide inside some custom compressors like this. That would then return to the original air supply. With this I am hoping that I will have a self-supplying system with ideally no more than 5% leakage, or enough compressors that leaks are compensated for. WIth the Parson's Turbine, that can be an accurate shell with whatever is needed inside to include a working turbine, and probably with an gearbox and ascending set of gear ratios to give it the necessary torque. These engines and turbine are meant to actually turn the propellers, perhaps even in water! Some other features would include a replica of the Brown-type reversing engine on the side of each of the Recip engines, making it so that the Stevenson-type eccentrics can change the direction of rotation. Considering the scale, the reversing engine doesn't technically have to be much more than a slightly-hidden piston that does the required job, but any more realism doesn't hurt. If something like this is possible, please let me know. I am really wanting to continue with this project, and this is a central part of it. But without the pieces in front of me instead of on a computer screen, what little I know of engineering definitely doesn't help without that tactile interaction. Thanks for your time, and I look forward to your replies! If it is possible, then I can follow up with the intended dimensions. Here are some references for any that wants some: View of turbine and condensers through wall from main engines rotor shaft model of port-side recip. engine overall basic view path of the steam of original, pressurized air for mine- 24 replies

-

- turbine

- air-powered

- (and 5 more)

-

Compact Pneumatic Excavator + My own sketch

Aventador2004 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi all pneumatic lovers! I got a kit of pneumatics a while ago, but haven't fully used them. Today is the day I show where they are headed. This is built to teach other people about excavators and pneumatics. Pneumatic pump (exhaust pipe) Pneumatic arm lift (2x11) Pneumatic dipper & curl (1x11) Cabin Access to hoses Tracks Spinning turntable (infinite rotation) Hope you like it as much as i do, and here is a hand drawn sketch I Made specifically for it. before you ask, yes i reprinted it. Who doesn't want the original. And now the model: Panel removed: Reach capability: Love it or hate it, i would enjoy to here what you think! -

[MOC] 8x2 Truck w heavy duty crane + instructions

Ivan_M posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I would like to share my latest creation - 8x2 truck with crane. This is the picture that inspired me: I started with cabin and chasis and I was not sure what kind of truck I want in the end. I was sure about one thing - not to make overcomplicated build so 8x4 dump truck was on my mind for most of the time. But then I have seen a website with cranes and the one above is very nice so it was set. I love pneumatics so this was an obvious choice. I have of course took the picture as purely inspirational, this is not meant as exact copy. Features: 3 steered axles, each with different ratio and all of them with ackerman geometry - I just love the small ball joint hubs. 3rd axle drives fake V6 engine (1:3 ratio) cabin with openable doors, openable front grill and it can tilt to reveal engine extendable outridges (6 studs), all operated simultaneously by knob behind the cab and pneumatic foots. They can lift the whole truck but they bend under the weight. 3 section crane with extendable 3rd section and winch. The crane itself is quite powerful, the limit is the winch. Slew is controlled by knob behind the turntable. huge amount of tubbing, almost 3,5 meters IMGP5104 by Ivan Moc IMGP5107 by Ivan Moc IMGP5108 by Ivan Moc IMGP5111 by Ivan Moc IMGP5112 by Ivan Moc IMGP5114 by Ivan Moc IMGP5115 by Ivan Moc IMGP5116 by Ivan Moc -

Ropa Maus 5 Sugarbeet Loader

BondemandClausen posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

NEWS of 12-11-2017: I have been invited by Ropa Maschinenbau, to join them at Agritechnica in Hannover Germany with my Ropa Maus 5, and my Ropa EuroTiger 4 XL, the coming Thursday and Friday the 16-17. in Hall 25, Stand G14. Come and have a look if you plan to visit this exhibition. Hi Guys, long time no see. Bondemand Clausen is back with some farming equipment. It is a Ropa Maus 5, which is used for cleaning and loading sugarbeets onto trucks or tractor wagons. This MOC is build in Scale 1:16, weighs 8 kilo. It has been presented at Lego World 2017, Copenhagen, and Skaerbaek Fanweekend 2017. First pictures shows the Machine in transport position. Unfolded and ready to work. It has 23 motors, 13 Servos, 2 XL, 3 L, 4 M and 1 Micro. They are controlled by 6 Sbricks, via Ipad. 10 of the servos controls pneumatic valves, powered by 4 pneumatic pumps. It has 11 pairs of PF LED lights. The real machine the Ropa Maus 4, Cleaning and Loading my Sugarbeets in 2013. -

[WIP] Tigercat Skidder

agrof posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi All, I know, I have unfinished projects enough (published here too), but time for another long-term build. I was lucky enough to find great deal on pneumatic cylinders, and finally I own Claas tires too, these caused to raise the Skidder-particle ppm in my haemodinamics. This is a very old plan of me, basically since I got back from my dark-age with the 8265 in 2009. So this is the plan: http://www.tigercat.com/product/630e-skidder/. I will not build a specific model, but a generous one (610/620/630/632 mixed style), because I am not that much interested in specific models - simply: I love them all (and beside that I am afraid of @M_longer's justifiable criticism ). Finally I found a working design for the grapple with nice range of movement. It has virtual pivot points, and floating cylinder (this is already differs from real-life counterparts), but I wanted to use 1 cylinder only due to tubing - which should be nicely hidden in the boom panels. Some might be not a fan of the Bionicle parts, but I find them right here, and they tend to close properly due the lucky combination of build slack and their pointy-thin design (I might figure out an offset for them, but wasn't successful yet). I made a pure Technic version too, in case. This is how it looks so far (partly built in bricks too - waiting for parts), with Power Puller tires in the model for the scale: Still a very long trip ahead, and I am not fast on building, but I feel passionate, which is a promising sign I guess. Special thanks to: @Lipko for inspiration and for the pneumatic parts in LDD from his majestic Backhoe, @nikolyakov for the beautifully purpose designed and inspiring TC10 entry, @BrickbyBrickTechnic for his 42054 C-model as final motivation, and for Bricklink to make it feasible to emptying my wallet... Every suggestion, criticism for improvement is welcome. -

-

- tc10

- pneumatic

-

(and 82 more)

Tagged with:

- tc10

- pneumatic

- technic

- moc

- engine

- 4 stokes

- nz

- lego technic

- v8

- impro

- tv

- wliia

- whose line

- comedy

- star wars battlefront

- the empire strikes back

- 1.4 fd p-tower

- battle of hoth

- at-at

- at-st

- star wars rebels

- rebel alliance

- a new hope

- return of the jedi

- rogue one

- city

- town

- bank

- key bank

- lego ideas

- landmark

- moc

- arc de triomphe

- france

- ag

- mantis

- technic

- scania

- truck

- yellow

- lowloader

- moc

- cv-project

- trailer

- mall of america

- lego shop

- lego brand retail

- lego store

- moa

- truck

- rc

- challenge 4a

- oleon

- 3rd party

- kit

- drone

- lego

- modular

- block

- lego

- modular

- building

- ideas

- brick

- minifig

- afol

- moc

- house

- falcon

- millennium

- design

- vedosololego

- micro

- custom

- furniture

- room

- diorama

- advent

- calendar

- city

- 2016

- octan

- ag

- rexgain

-

Help with pneumatics - Arocs Mercedez

papa lalo posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Ive just assembled the arocs mercedez truck. Wow its big but the pnematics dont work at all. Pumps on, slight movement but not enough power to lift anything. How does one know if the pump is putting out or mal functuioning or valve mal functioning. Im frustrated a bit. Seems at best the pneumatics system is weak to begin with. Do the little blue pumps often cause trouble. It is a new set. Thanx -

Self-Powering LPE Idea

RcRacer99 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I am a fairly new member to the Lego community but have immediately been interested in LPEs. Here is my idea: Has anybody ever built or thought about powering a compressor with the engine itself. So instead of having a compressor powered by a PF motor, connect the crankshaft of the engine to it. This removes the need for the motor entirely. You will obviously need some sort of external pump to get the engine turning over as a start, similar to a starter motor. The other problem I have thought of is that it will create a never ending cycle of the engine going faster and faster and faster, assuming that the compressor can produce more air than the engine needs and vice versa. I currently do not have the resources to test this myself so any feedback would be amazing! Is this a stupid idea? Are there other things I haven't thought of? What are your thoughts on this project? Thanks!- 7 replies

-

- compressor

- pneumatic

-

(and 2 more)

Tagged with:

-

Yet another little excavator. Jono Rocky's model was great, but one main thing I wanted to add to that model was some functions to the undercarriage. Then Efferman started his Liebherr Compact 926 project and figured I could add another cylinder to Jono Rocky's arm. This is the result: As you can seen, also used the standard Liebherr colours. Yellow and DBG just happened due to the panels at the rear and the colour of pneumatic switches and I figured I'd use white for the cab instead of "yet another black cab". It isn't scaled to existing Liebherr though. Functions: - Full functional pneumatic arm - Pneumatic dozer blade on the undercarriage - "L2" engine (let's say it's a little "out of sync" though more on that later) - Full 360 degree turn with controls at the rear I was pretty surprised the blade holds the entire model up, especially after every single cylinder on the arm nagged about hoses not being the right length or in exactly the right position. If anybody has any suggestions to make the hoses less stiff (some kind of oil?), I'd love to hear it, because this was just stupid. These panels just screamed: use me here and never ever remove me from this place I added a second pump to the undercarriage so the superstructure could turn 360 degrees 1millmeter of play between the gears+axle and hoses I actually wanted to add another function: cabin lift, but besides having a lack of space behind the cab for this (hoses) it would have a serious negative effect on the support of the arm. So I dropped this idea. I didn't really like having the controls for the turntable stick out at the rear so much as this, but I had no room for other solutions. I tried lowering the "knob" one stud so it wouldn't have to be that long (it's this long so it doesn't collide with the superstructure while actually turning). I tried looking for a way to make a sliding mechanism, but there was simply no room. So I settled for this third option: removable and click it elsewhere on the body. I didn't try to close up the whole rear with tiles, mainly because the hoses ruin any type of mounting points available. On the other hand I like seeing a bit of "the guts". Especially when I spend quite a few evenings on these "guts" (hoses) to get it to work properly The L2 is poorly tuned In the space available my options were limited. I used @Attika's half pin solution for the fake engine, but these pins won't work with plates with a clip on top, because they can lock up on these pins. So I needed parts that were round on top. I could only think of this crankshaft part in the 2x2x2 studs space available. In this WIP you can clearly see the current situation: I added the 2L thin liftarm for the simple reason that I like the engine more going 2 up> 1 up> 2 up etc. than 2 up > nothing > 2 up. Neither option is realistic, so I chose what was most fun for me With his other pneumatic buddies: Some WIP pics That moment when you realise that your superstructure is 1 stud too long or your undercarriage 1 stud too short... I tried making the superstructure 1 stud shorter, but that would really hurt the rigidity of the arm. So I made the undercarriage one stud longer, which funny enough was a bit of a puzzle to make it bigger, but in the end it turned out better (mounting of the blade didn't stick out on top anymore for example) and the whole undercarriage is stronger than it was. No idea how much hose I used. Jono Rocky was at 1.3m of hose iirc, with 2 more pneumatic functions I am probably closer to 2 meters. There was an attempt to add a diff to this model, like the previous models I made. However due to the size of the diff and the ground clearance it would turn out something like this: As we all know from Sariel's gear calculator, there isn't a combo of gears for 1 stud down+1 stud right, but these bevel gears with half a studd offset, work pretty well for this purpose (though I doubt it would play nice with torque from a motor). It even has that, as @Didumos69 would say, "sweet Lego gear rattle". It's probably common knowledge, but it was funny to stumble upon this during the build and something I might find another purpose for in the future. I decided to drop the diff from the model in favor of the dozer blade function. I also dropped the scale of this diff concept, because the bucket would be too big. I didn't want to build a smaller bucket or use one from normal Lego, so I decided to scale up to the normal Technic bucket. In case you wonder why there isn't a video of the pneumatic functions. I tried, but my big paws block alot of the model when operating the functions And here's a video of the pneumatic functions, don't ask me why I didn't think of holding it this way yesterday... Thanks for reading yet another too long post from me

- 24 replies

-

.thumb.gif.ad7c8d88b264ee812194946c07404504.gif)

[MOC] Automatic Motorized Compressor

mocbuild101 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

This MOC came about from my wanting of a super compact all-in-one Lego compressor, and after trying many different auto valve designs (and about a week of building), this is what I came up with: Video: Features: Air tank Automatic pressure switch M motor and 6L mini pump compressor Very compact 15 x 11 x 7 stud size Easy removal of battery box Pneumatic tube lengths: 1x 3L (2.4cm) 2x 10L (8cm) 1x 14L (11.2cm) All the pneumatic tube lengths listed above (and most of the other parts) are available in 8110-1 Unimog U400. Instructions are available on Rebrickable. The compressor uses a single 6L mini pneumatic pump, but can easily be modified for two pumps. The automatic cut-off pressure can easily be adjusted by changing the strength of the rubber bands attached to the pneumatic cylinder.- 20 replies

-

Hello everyone. I would like to introduce my truck with excavator. It is loosely based on Tatra 815 with UDS 114 (universal finishing machine). The real thing looks like this: I really like this type of excavator, its main advantage is high mobility because it can even go on highway. It is mainly used on road building and terrain shaping. My goal was to make pneumaticly operated truck, preferably playable by kids. I started with some blueprints and decided to use 49,5mm wheels that set my scale to roughly 21,5:1. I wanted it to look like an older truck, with low cabin and boxy design. The model features: - HOG steering by spare wheel at the back of cabin - Openable doors with decent details in interier - Fake V4 engine that is connected to rear axles, each with differential and with shock absorbers (~1 stud travel distance) - Pendular unsprung front axle with ackerman steering (~3 studs travel distance) - Pneumatic stabilizers that are able to lift the whole truck - Pneumatic jib with manual extension from ~40 to 68 studs - Manually operated bucket with 360° rotation The above is a result of many compromises - like V4 engine instead of inline 6 etc. It is not possible to fit larger engine into this scale, I tried mini fake engine but I didn't liked how it looks. What is most satisfying for me is the front axle with ackerman steering and pivot point nearly in center of the wheel. That allowed me to build very nice fenders close to wheel. The wheel doesn't touch it even in full turn radius and fully compressed. The rear axles are by Efferman, he used this design in his Kenworth crane. I really like it. Enough talk, some pictures: IMGP4963 by Ivan Moc, on Flickr IMGP4964 by Ivan Moc, on Flickr IMGP4965 by Ivan Moc, on Flickr IMGP4966 by Ivan Moc, on Flickr IMGP4968 by Ivan Moc, on Flickr IMGP4969 by Ivan Moc, on Flickr IMGP4970 by Ivan Moc, on Flickr IMGP4971 by Ivan Moc, on Flickr IMGP4973 by Ivan Moc, on Flickr IMGP4974 by Ivan Moc, on Flickr The weight of the fully extended jib is pushing the thin pneumatic cylinders to their limit. I wanted to keep thin ones at all cost because they look much better. I have redid the jib like 15 times, ending with studded one that prooved the best abilities in terms of rigidity, weight and looks. The battery box is there as counterweigh only. I had several versions with PF - to run compressor (not enough pressure to lift fully extended jib), motorized jib extension (took too much space from the extension),.. so in the end I threw PF out, leaving all functions as manual. The stabilizers were also quite challanging due to the angle and size, at least they have no problem lifting whole truck. I hope you like it.

-

Hi everybody. last month I started a new project, while my 42043-C Unimog U4000 is on standby. I kinda like the Mercedes Benz team. so this one will be another Zetros. while my 42043-C Zetros was a C-model, this Zetros 3643 AS 6x6, will be way bigger, and not a C-model. Below is the blueprint I'm actually building from. been during a lot of research, blueprints and calculated a proper scale many times..... so by basing the scale on the wheels I figured out that a 1:12.5 scale would fit very well. I got some RC wheels 108mm, which kinda looks like the Zetros tires, but the Claas Tractor tires will fit the model very well too. Now let me show some pictures of my actual model so far. This one was my first atempt to build a proper fitting chassis for the Zetros But after a month with rebuilds and testing, I got to scrap that design, as the gearbox wasn't strong enough to power 3-4 kg of lego. also was the chassis a bit to flexible. so during january I ended up with this design: And by now I have finished most of the chassis, on moved on to the cab. As told it is the CrewCab model I'm building, mostly because it is the one I like most, and think it fits the size of the truck very well. By finishing the Chassis, it also means that bumbers and headlights are done. I'm not quite sure about the headlights yet, but it will work for now. The picture above, is the current prgress. More will follow. more pictures at: https://flic.kr/s/aHskRFHEQB

- 21 replies