Search the Community

Showing results for tags 'Excavator'.

Found 86 results

-

[MOC] Excavator. Single motor, fully functional.

McMarky posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

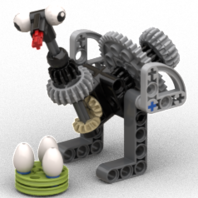

Hello guys, Do you like oldschool Lego Technic with a single motor and many functions? I hope you would like my excavator. It has only a single PF L motor and is fully functional. It can drive and dig. Enjoy the show 😀 -

I again wanted to go big on this build. Like BIG. So I went 1:16 scale the best I could. I started with an existing design from a failed build. The plan is to have 2 PF-L motors for the drive, PF-XL for the boom, and PF-M for the rest. Please note that I'm almost done with the build, but I am making minor adjustments to the build to help with function and/or weight support. I will be posting here to "show my work" of sorts and get feedback. I have been busy catching up on other things and building the excavator. (not much free time for posting/commenting on here) This was the first version of the bottom: And the start of the upper: It was looking good, sort of, I had to redo all of it as I add the battery boxes and arms it had a weak structure and was "clunky" in functions. I have remade all of the above and will post more in the morning to not have too many pics in a single post.

-

42144 Mod - demolition excavator

mpj posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hello, I show you my latest build. It is a mod of set 42144. I was really disappointed by the aesthetic of 42144 material handler, but I think that the arm and the turret has been well designed. And I changed everything else. New tracked undercarriage, new tilting cab (not lifting) and new grapple (too look more similar to a demolition grapple). I tried to minimise the use of extra parts at the strength necessary. Instructions are available on rebrickable: here I hope you like it! -

[MOC] 42148 Excavator

ilyabuilder724 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

My First aternative build for the 42148 set. A simple Excavator. I hope you're gonna enjoy the build! Feel free to share your pictures of assembled model! FEATURES Working Tracks Working Excavator arm- 4 replies

-

- alternative

- b model

- (and 5 more)

-

Earthmoving plant package

BIGRIG2005 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

My new MOC consists of a couple of items to form a big earthmoving plant package. 1. 42078 c model, Renault AE Magnum tipper and dual axle plant trailer. Truck -HOG steering -tilt cab -opening doors -working E9 V8 Mack Diesel engine -tipper with lockable tailgate -hitch at the back to couple to a wide range of different trailers. Trailer -floating pin hitch -folding legs -droppable rear ramps via small actuators -bed toolbox to store wheel chocks, chains etc. 2. 42053 c model, backhoe -4 wheel steering -quick hitch on the loader -tilting hitch on the loader -outriggers -sliding back actor with pin locks to hold actor in place. -quick hitch bucket on back actor -swinging actor with locks to hold in place for transport purposes -lift and extend functions for back actor -pneumatic functions for back actor and front loader tilt hitch -manual functions for back actor bucket angle and front loader lifting and lowering. 3. Mini excavator made from my spare parts box. -lifting and lowering as well as extension of excavator boom -front blade -swinging of main frame -tilting bucket Altogether this creates an ideal construction and earthmoving plant package. Hope you all like it. -

Alright, I'm a little late to the game, but I want to play. I confess I am still on the fence about doing a front end loader, so I'll give my draft one more go this weekend, and make a decision about if to move forward with it. But, ever since @Jundis started his Mecalac 12MTX WIP, I, like many of you I'm sure, have been spending a lot of time on the Mecalac website. They have a lot of fun little machines. Each would make a fun little project. For this contest, I wanted to see if I could do a little skid excavator. I finally got a little time to build this week, and here is what I have so far. It's pretty basic (and sorry I burned out my photo lights today), but it is a good start to see what I can fit. The MOC is currently 26 modules long, 20 modules tall, and 17 modules wide which equals 8,840 cubic modules/studs. I planned the project at 29x20x17 (9,860), so I should be fine. I suspect the MOC will get a little longer and taller, so it is good I have a little bit of space to expand if needed. Currently I have the following functions, all of which are manual: Front Plow up and down Slewing from HOG Boom 1 up and down Boom 2 up and down Boom 3 in and out Bucket scoop Interchangeable bucket I have a lot of room in the back, so I hope to do something else with that, and the cabin will have a door or something. Everything right now is a rough placement, but the movement of the boom is acceptable, so the pivot points might be effectively "fixed" at this point. We'll see where this goes....

-

excavator Liebherr 984 LEGO Model Team

amon161 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I present to your attention the Liebherr 984 excavator. Liebherr 984 Model weight 6.5 kilograms Model width 30 stud Chassis control two M motors with separate BB Pneumatics control three M motors and an XL motor for turning the tower as well as with B For pneumatic pumps a separate L motor with BB -

This is something I came up with after starting a build of wheeled excavator from scratch. My previous model had overcomplicated design of the chassis and used small linear actuators for arm movement which was pretty bad for a manual model due to the amount of cranking required. I also got rid of steering elements I often used in my previous builds as they are not that common anymore. The one of the arm controls use single lever for two arm movements - bucket movement and arm movement - this is made possible by differentiating the torque required for string pull with a wheel. The video shows building of the chassis and operation of this excavator arm prototype I'm planning to build a full excavator model on this, hopefully with full fledged instructions, but it'll take some time, so stay tuned if you like it.

- 16 replies

-

- excavator

- wheeled excavator

-

(and 1 more)

Tagged with:

-

[MOC] Poclain HC 300

Leviathan posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi everyone, Today I want to introduce to you my latest MOC : a Poclain excavator, the HC 300. Poclain is a French company (bought in 2000s by CASE) leader in 60-70s in hydraulics excavators and engines. The HC 300 was the bigger excavator in the world in 1968 ! Specifications : I wanted to control the model with a smartphone so I used Control+/Power up applications. The excavator has also manual features. I used electrical linear actuators instead of pneumatics to enhance playability. The excavator must be able to rise one track from the ground by using the bucket and his motorized arm. Inventory is mainly based on #42082. The main design is based on 8043 set. The drive train is powered by 2 L motors and a dual differential drive : more informations on @Sariel video : https://www.youtube.com/watch?v=f5_OQooBxdY. This kind of transmission allows control by only one joystick one smartphone screen instead of two sliders. Configuration : 6 motors : 5 L motors (https://www.bricklink.com/v2/catalog/catalogitem.page?P=bb0959c01#T=C) and 1 XL motor (https://www.bricklink.com/v2/catalog/catalogitem.page?P=bb0960c01#T=C&C=85) 2 electrical hubs 2 000 parts Features : - Toggling cabin with mechanical locking system - 360° turret rotation : One battery box is placed in drive train and the other one is placed on turret. No cables through the turntable, only a shaft to transmits rotation from drive train to the V12. - Technical compartments : a lot of openable elements very useful to store tools and tracks components. The grid at the back can be opened to reveal V12 engine. - The entire bodywork is removable. It is only set on the turret by gravity. The entire of the excavator is modular in order to make disassembly easier. - V12 engine works when the excavator move. I add a maximum of details to make it more realistic. - The dual differential drive : Each motor drives one kind of motion, straight-line motion or rotation. Get more information here : http://groups.csail.mit.edu/drl/courses ... ldiff.html. You can also combine motions to get curved directions. Tension on tracks is maintained by springs. Originally made by @Anto : https://www.techlug.fr/Forum/viewtopic.php?f=5&t=11548 Inspirations : https://rebrickable.com/mocs/MOC-1312/yannmar/motorized-hydraulic-excavator/#detailshttp://www.techlug.fr/Forum/viewtopic.php?f=5&t=11548http://www.techlug.fr/Forum/viewtopic.php?f=5&t=11878&p=192932&hilit=excavatrice#p192932https://www.techlug.fr/Forum/viewtopic.php?f=5&t=11343&p=185867&hilit=excavatrice#p185867https://rebrickable.com/mocs/MOC-19850/Mowlwurf/42006-full-rc-mod-undercarriage-with-transverse-subtractor/#comments Conclusion : The video will come soon ! Building instructions too ! I hope you liked this creation, I tried to mix up realistic details and common excavator's features. Only displacement is slow because of a total weight of 2kg. HD pictures here : https://flic.kr/s/aHsmVM6rX2- 31 replies

-

[MOC] Mining Dump Truck - Lego Technic 42114 Model B

eric trax posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Building B-models between major projects has become quite normal for me. Such a break and playing only with Technic bricks is a very good way to reset my mind 😊 This time it was the 42114 set and the Mining Dump Truck was created as an alternative model, for the excavator from the 42100 set. The plan to build this vehicle from the 42114 set appeared a few months ago. I put it off for later, because I thought I wouldn't have enough panels to build a nice dump box. Over the weekend, I sat down with bricks and in a few hours the first version of the tipper was created. I liked it so much that the final version differs from the prototype only with minor changes. The biggest difficulty in building this model was its size of frame. When planning, I insisted that the model must use the original app, because that could be easily configured and played with it immediately. The machine has double wheels on the rear axle, so the frame basically contains the engines, gearbox, and a rear axle. In addition, the set has only long actuators so placing them in the dumper was also not easy. At the end, everything was packed into a pretty nice model, which uses over 78% of the set elements. The tipper was supposed to look good with the R9800 excavator from the 42100 set. So I scaled the Liebherr T282 to 1:42 scale and built the model on it. The appearance of the dump truck is a combination of the previously mentioned Liebherr and CAT 793F. It is not an exact copy, but there are similarities. Building instructions: https://rebrickable.com/mocs/MOC-76959/M_longer/42114-mining-dump-truck/ Check out photos and a short video presenting the model's functions: Video: -

[MOC][WIP] Excavator

gvo25 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hello All, Recently I bought the lego 42114 volvo dumptruck and before I would build that I wanted to build an excavator to go with it. While Flybums excavator is a very good one I wanted to try myself to build an excavator. Here are some WIP pictures. As you can see the top part of the excavator uses the normal power function motors. 1 x L-motor for swinging, 2 x L-motors for the main boom, 1 x L-motor for the stick and one m - motor for the bucket. The main boom houses two motors and is my own design, the stick is an exact copy of flybum's excavator. The motors use use two AA-battery boxes and the AAA battery box is used for ballast, and will later power the lights. The crane uses a normal turntable, as i find the big ring gears too big for this scale of excavator. The top part wobbles a bit while turning but it's definitely within limits. The trackbase uses 2 control+ XL-motors integrated into the tracks with a worm gear and normal gearing. The battery box is situated just below the turntable. -

42121 Heavy-Duty Excavator Full RC MOD

Seo-onDaddy posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I converted the 42121 Heavy Duty Excavator to a RC version that can be driven and moved. * Instructions are being distributed by Recrickable. https://rebrickable.com/mocs/MOC-69683/Seo-onDaddy/42121-heavy-duty-excavator-full-rc-mod/#details * A 4-port receiver such as 'MOULDKING' receiver or, 'CaDA' receiver or 'Buwizz' is required, and case separation is required.'MOULDKING' receivers do not require any work other than case separation.The 'CaDA' receiver or 'Buwizz' must be removed from the case and the battery must be replaced in a small size.Battery size should be less than 14mm x 25mm x 50mm. * I modified some parts of the exterior because the space was cramped. * fixed the range of operation of the arm operation. -

Hello everyone: I am glad to share this project, the mining excavator, based on Cat 6090. Phisycal Configuration: The Lego Cat6090 is a motorized digger on tracked wheels, 2 XL motors provided enough torque. On the track frame is placed the main structure, and a heavy duty turntable allows good rotations, without fricctions. The turntable is rotated by means of 1 XL motor. The main structure contains: the XL motor for turntable, the air compressor, 4 servos for pneumatic valves and the controller. The design is ultra compact in order to meet the requierement of size/scale. The tracked whell is ultra rigid structure, designed to resist extreme load. The air compressor has 4 XL motor and 2 pneumatic pumps, in order to provide a constant air flow and high pressure, both pumps are de-phased 180° in order to reduce vibrations. 4 PF-servos open/close 2 way air valves, to command all pneumatic actuators. The boom has 2 large pneumatic actuator. Due to heavy height of the boom, 4 spring supply extra force during the elevation. 2 large pneumatics actuators push/pull the arm, those actuators are placed below the arm. 2 large penumatics actuators dedicate to rotate the bucket. 1 medium pneumatic actuator, open/close the bucket. Electrical configuration: Three 18650 batteries provide an average of 11.1 V, the compressor are suplied with 11.1 V, and the servos, lights and turntable motor are suplied with 9V. A BMS (Battery Managment System) manages the charge and the discharge durgin the operation. The tracked frame is steering by the use of 11.1 V, and as well is manage by the use of a BMS. On Board System (OBS): The name given to the controller. There are two systems, one for the main structure, and the secund is used to move the tracked well. The main controller, is a server TCP/IP protocol. The controller has a ESP8266 microcontroller with a TCP/IP stack, this controller is able to be programmed in arduino languaje (also micropython) - Teh ESP8266 is used as a sever, Motor driver: used to control the compressor The 4 PF servos are controlled by means of digital outputs, and the lights. ld293d, this is a H-bridge used to control the turntable motor. The second controller, is a ESP8266 as a client, and controls the speed of the tracks. Also, it has a BMS in order to regulates the charges/discharge of the batteries Accessories: 1) Josyticks: Two joysticks, with 4 dof (degrees of freedom) each of one plus a on/off button, are connected to the server module. 2) App: An application developmented under Android studio is used to visualizate the air pressure and electrical current, this app is WIP (work in progress). Conectivity: The comunication used is socket TCP/IP- Main features: maximun pressure reached: 52 psi (358 Kpa) Voltage bus: 11.1 V Compressor electrical consuption: 23 W Weight: 6 kg Length: 30 cm width: 20 cm height: 30 cm Here some pictures, during the construction and commissioning Note: my apologies for my primitive english

-

Generic mining machine

jorgeopesi posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

It will be a front shovel or a excavator or both. My challenge is not to have reference, I want to do it strong and playable with the less pieces I can. I started with the tracks and it was not easy at all... all the weight rest over the six small wheels to have less friction on the track gears and you can take off easy the turntable, each undercarriage and the center part. I would like to know if the small tracks will be a good idea to move the machine, I think I will have to do a test with a lot of weight to test it. I did not like at all the 42100 tracks because they are too big I wanted mine just 9 studs high. I still have a lot of work to do so I am quite happy.- 21 replies

-

- excavator

- front shovel

-

(and 1 more)

Tagged with:

-

[WIP] Telescoping boom excavator

howitzer posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

While excavators are long-time favorite of Technic, I recently saw something new in a construction site nearby: an excavator which had a boom that telescoped and rotated around its axis, instead of articulated jib. I then learned that a company called Gradall makes those, here's an example: So I set out to build one, though I make no attempt to replicate the looks exactly as some parts of this machine are next to impossible to replicate in Lego, at least in reasonable size. The first problem was the triangular cross-section of the boom, but very soon it became clear that it's not feasible so I settled for squared cross-section. Considering the functions of axial rotation, luffing and telescoping it also became clear that the motor driving the telescoping action would have to be located on the boom, and hoses for the pneumatically operated bucket would have to run the length of the boom and exit at the back so that there would be room for extension. I wanted to extend it as much as possible, and some 11-12 studs seems to be reasonable maximum. Here's a photo of one stage: Next in line was an attempt to build a superstructure which would support the batteries, pneumatic controls and gearbox for the axial rotation and luffing. At this stage I didn't even think of full motorization or remote control, I don't have PF parts for that and it was already complex enough. I got it as far as testing the motorized boom functions which more or less of worked, but I wasn't satisfied with the performance and there was a lot of problems with the gearing anyway. Here's a photo: At this point I was at sort of a crossroads: take apart and rebuild the superstructure to fix the aforementioned problems with gearing and try to finishing the thing OR make it even more ambitious with the Mindstorms Robot Inventor set that I just recently bought. It would have 4 additional motors (to complement the two PU medium motors I already owned) and hub with 6 outputs which could be controlled much better than what PF allows, enabling perhaps full RC control with proper programming. I chose the latter so that's what I've been doing recently. And it hasn't been easy. First I needed to decide how to use my motors and how to connect them to the functions. With motorized drive (2x tracks) and slewing in addition to the boom controls (axial rotation, telescoping, luffing, bucket switch and pump) there are more functions than the hub has outputs so some sort of gearbox would be required. The 8043 Motorized Excavator acted as an inspiration with its 6 functions for 4 motors, and I decided to try similar gearbox solution where 4 two-position selectors are moved with one motor at the same time so that in one position you can drive and slew and in another position all boom functions can be operated. I also stole the coaxial drive mechanism for tracks from the same set. Here's where I'm now in photo: And in digital model: I recently realized that it's almost impossible to use the angular motors in driving the boom extension, so I ordered a C+ L motor for that purpose and I'm waiting for that now. I also ordered a new type of pneumatic switch, so that it's easier to operate with motor. Some problems at this stage: Is there any way to make the boom support narrower? The problem is the gearing for axial rotation, which seems to be pretty much impossible to fit in between the turntables in any narrower configuration than this: Another problem is the gearbox construction, how to route all the functions to their places while still having the gearbox to be properly supported and smooth so everything works fine. Especially the axial rotation seems to be hard to achieve as there is a lot of resistance in the thing. With the earlier PF iteration I tried routing the gearing to both sides so that both turntables would rotate and while it sort-of works it of course introduces a lot of gears and friction. Turning just one turntable would have the force directed through the boom to the other turntable and that requires a lot of force too so it's probably not feasible. And of course I haven't even touched the programming side of things with the RI hub yet, but I suspect that'll be much easier. Any thoughts or tips? -

This excavator is one of many I've built over the years, but the first I've shared. It came about from looking at Google Image search results for "road rail excavator", with a good helping of inspiration from @Hod Carrier's excellent model. It's not based on any single prototype - the build was mostly dictated by what parts I had available! I decided to incorporate a series of strings to control the main boom, the dipper and the attachment, from gears on the side of the superstructure. Elastic is used to return the dipper and attachment when the string is slackened off - or it was, until the one I was using for the attachment split before I took these photos. It should be fixed between the black and DBG plates and at the top of the cylinder, to represent the hyrdaulic ram. The cab took several revisions before I was happy with it. It uses some frankly ridiculous offsets and SNoT, which I'm sure anyone with a wider parts selection could build much more efficiently! Hey, it works, and I managed to include an opening door so I'm happy. The rear side isn't particularly interesting; I incorporated the control gears into the grille areas so they don't stand out quite so much. Finally, thanks to an extra manual hinge point (just behind the spotlights), the boom can be folded up fairly compactly for transport... ... yet still has enough reach and stability to be able to lift and lay track panels. Thank you for looking! And if anyone's interested, more photos and the LDD file are available in my Bricksafe Folder: https://bricksafe.com/pages/Collet22/road-rail-excavators

-

Two very small steering mechanisms

blueShinyApple posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

About two black ages ago I came up with a mechanism to add steering to very small models, and I worked on two models based on it. I have never been able to finish them to my satisfaction, and I'm realizing the current black age I'm in will probably last until retirement, or at least until I get a bigger living space, so I'm posting what I have now. I should probably have posted about the mechanisms years ago, but I wanted to have some neat models to show off with it too so I never did. Last time I searched around the web for anyone else who had shown the mechanism off I didn't find anything, so I don't think it's a well known thing. Here's an album with pictures it this post: https://imgur.com/a/ixZOK0s Overview of the two mechanisms. Vertical and horizontal variants of the small mechanism on the left and bigger one on the right: Small mechanism with vertical axle: Same mechanism with horizontal axle: Here's the bigger mechanism with vertical axle: Here's a WIP wheeled excavator based on the smaller mechanism. The bottom right picture is another control scheme I was exploring. I'm mostly satisfied with the model, it's only the arm and bucket I don't like. Here's a bigger WIP model. This one uses very tightly packed pneumatics. It's missing the cab and arm, but I'm otherwise pretty happy with what I've got. I was never satisfied with the arms I managed to build. They were either too bulky or too fragile. This model feels very nice to roll around on the desk, it has some a weight and grounding that the smaller one lacks, and the turning is pretty satisfying too, even though it can't exactly turn on a dime. Lastly, here's a half scale model of the 8049. Lacking fenders, seat, lights and the trailer. I would like to get the two excavators finished one day so I can have them hanging out under my monitor, but my hobbies have shifted to electronics and plants, and I'm lacking in desk space anyway. Maybe one day though :-) Hopefully these mechanisms can help you in your builds! As a bonus, here's my collection of all technic excavators, except for the Liebherr, which I'm hoping to find used for cheap. Note the blue excavator from the 8888 idea book! If imgur decides to stop hosting the pictures, contact me on BL where I have the same username and I'll get them hosted somewhere else. -

[MOC] VOLVO EXCAVATOR - TRACKS EXPLAINED

Flybum posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hello everyone! I posted a new video to explain how I built the tracks and the tensioner for my cutom Volvo excavator. -

[MOC] 42108 Set Alternates

TGBDZ posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi there! At the start of January picked up the 42108 set (Actually wasn't planning on spending money on more Lego at the start of the year but saw a surprisingly cheap deal for a new set and just couldn't resist it). Naturally, opened the box, went through the instructions and applied all the stickers to their belonging parts and started to work on new alternates without assembling the original set (Yes, I'm a mad lad :D ) And who would have guessed.. my first alternate was another excavator.. I hope that people don't get exausted of seeing another one but this set turned out to be a great part pack for creating a sleek and fully functional wheeled excavator! Functions: Working steering - blue gear on the back Adjustable front shovel - manually, can be locked in place Adjustable rear outriggers - mannualy, can be locked in place Rotating upperstructure - Black knob at the rear of the chassis Fully functional arm - controlled by 2 seperate knobs on the top of the upperstructure Chasis storn enough and with the outriggers and shovel extended it can support the whole weight of the excavator and lift it from the ground. At this moment this is the second set that uses the new Large linear actuator, and it just makes reach on this medium sized excavator crazy good If You want to build it Yourself - Instructions available here: https://rebrickable.com/mocs/MOC-38023/tgbdz/42108-alternate-wheeled-excavator/?inventory=1#bi (Or simply look for TGBDZ on rebrickable) For the next build I wanted to make something different that I haven't tried before.. After Some tinkering with the parts a bit I started to build a rather large structure using the larg 3x11 curved panel pieces and after creating a large bathub like structure I decided to make an articulated hauler. I had atleast 6 wheels, for the center joint I could use the turntable, large actuator should cover the lifting of the cargo bed - all the major issues were solved quickly and here is the result. Functions: Working steering - no HOG - the center of the cab is so close to the swiveling point that it's easy to steer by pushing on the cab sides Fully adjustable chasis/suspension - front axle is solid and together with cabin is rotating on the turntable located in the center of the chasis - rear axles use double wheel boogies that easily gets over small obstacles Functional and tipping cargo bed - uses large actuator and is operated by knobs on either side Cargo bed can be locked at the back to prevent unecessary spillage of goods And just like for the excavator - I think the original 42108 stickers add a lot of nice touches to the design. Instructions for the Hauler will be available soon. What should I build next? At the moment I'm thinking of making two models at the same time - 42108 has 8 aviable wheels.. Will see :) Cheers! -

NEW LEGO VOLVO EXCAVATOR 2020 MOC

Flybum posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Inspired by the Volvo EC750 Excavator with the new Powered Up motors All motors in the rotating platform Tracks with subtractor mechanism and two differentials Tensioner regulated tracks- 80 replies

-

- technic

- control plus

-

(and 5 more)

Tagged with:

-

[MOC] Skid Steer Loader - Lego Technic 42100 Model B

eric trax posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hi. Guys! :) The high pace in building agricultural models I imposed myself last year meant that I had to take a break. I need something completely different and new challenges. Then I decided that it would be interesting to build an alternative model for the official set. The limited amount of bricks always boosts creativity. The 42100 set doesn't have a B model at the moment. When I saw model of Bobcat loader build by my friend Makkes', I thought it might be a pretty interesting idea for an alternative model. However, I didn't want to build a typical skid steer loader. Looking through this type of machine, I found the Bobcat T870. It is interesting because it has additional links and support arms. For what? Well, to get the vertical lift path. The whole system eliminates the bucket moving back effect and this makes loading onto trucks much easier. I built a loader in just over two weeks. Scaled to the wheels gave a 1:9 result. From the first pin, I planned that the model would be built modularly. It caused me a bit of problems but I learned a lot and the whole construction contains 14 modules. I started by building caterpillars and I am very proud of them. Technic links are very well stretched much better than in model A. The model is not complicated but its construction gives a lot of fun for example connecting the caterpillars with the frame and then the drive. When I ran out of one cardan, I decided to assemble it from the available elements. I wouldn't be myself if I didn't take care of visual issues. I knew at the planning stage that I wanted to finish the cabin with pneumatic hoses as a cage. I added many details such as oil tank, distributor, radiator, muffler. When we talk about visual details, operator's seat is my favorite part. I am aware that the model does not use the full potential of the set. Only a Control HUB and three engines and some parts are left for use. I treat this model as a warm-up before the next one Marek, as usual, create building instructions for the model and of course he did a perfect job. The original application is not suitable for control this model, so I decided I would create another instruction for the BuWizz application so that everyone could easily configure it. Model dimensions: Length 42cm, Width 23cm, Height 26cm, Weight 2480 gram Drive 2x XL, arms lifting XL, tilting bucket L motor. The building instructions are available at: https://sellfy.com/p/dwatsg/ https://rebrickable.com/mocs/MOC-37222/M_longer/42100-skid-steer-loader/ Photos and video below. This is my first alternative model so I am interested in your opinions. -

Liebherr HS 8040

Porsche96 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Liebherr HS 8040 Specification Length 40s / width 23-29s / height 21s (32/18-23/17 cm) – without boom Scale: 1:18 Maximum height depending on the lenght of the boom I 70 cm – equivalent 11m II 87 cm – equivalent 14m III 102 cm – equivalent 17m IV 121 cm – equivalent 20m Weight: 2945-4014g Power supply 2xBB 8878 Controlled by two sbricks 2x M 3x L 2x XL Functions Driving - 2 Ls Track sliding - M Rotation of the uppercarriage - M Lifting boom by a winch – L Two winches for moving the bucket – 2 XLs Today, I’d like to present you a dragline excavator Liebherr HS 8040. I came up with the idea of building such a machine after watching a movie from Brick Creek exhibition. The whole construction was made in about two months. For driving I used two L motors, which power both tracks with ratio 1,67:1. Because of that ratio the excavator is pretty fast (maybe too fast for such a machine). Because of variable track spacing there is no space to add other gear reduction, while maintaining the stability of the structure. The tracks are slided by four small linear actuators, driven by M motor. The mechanism of retracting tracks is based on guides of three studs height and one width. They come into the undercarrige, based on two cnostructions made of 5x7 frames, and connected by the system of sliding tracks. Details in photos below. The uppercarriage is mainly based on frames, connected by liftarms and housing made of technic panels. For rotation I used M motor with ratio 120:1. Three winches are made in similar way: the string is wound on a sleeve on an axle, between two 36 gears, driven by 12 gears. For lifting boom there is one L motor, and for moving the bucket there are two XL motors. I used modular counterweight, like in the real excavator. In the lightest configuartion it weighs 319 grams and consists of a battery box and back cover of the excavator. The heaviest configuartion of the counterweight it weighs 1140 grams. It consists of the lighter configuration and additional battery box, cover and lead weights (8x70g), which are protected against movement while driving the excavator. Boom is a simply, durable construction made with liftarms. Most angular connections are „legal”, but because of the narrowing of the first and the last section of boom, not all of them are. But they fits with no problem. Boom configuartions: I) I + IV: 30s + 44s, max height of the excavator 70 cm II) I + II + IV: 30s + 21s + 44s, max height of the excavator 87 cm III) I + II + IV: 30s + 42s + 44s, max height of the excavator 102 cm IV) I + II + III + IV: 30s + 21s + 42s + 44s, max height of the excavator 121 cm I built two buckets: a dragline bucket and a clamshell bucket. The excavator can be also used as a crane, but while lifting heavier element it would require bigger counterweight. Before I started the building, I wanted to make something fully modular. I think it worked out :) Operating the excavator is not easy, it requires a little of experience, which I am achieving. This type of machine is designed primarily to dig below the ground on which it stands (f.e. dredging water reservoirs), that’s why it’s hard to dig from a flat surface. I encourge you to like my new fanpage. Gallery -

[MOC] Liebherr R 980 Excavator 1:25 motorized

Brickzone52 posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hello Everybody Im happy to introduce you my Liebherr R 980 excavator scalemodel 1:25. The whole excavator is fully motorized with power functions. The goal was to combine the motorized technic world with the usual lego bricks. Was not that easy because of the weight. This beauty will be for ever with me, thats why i also builded up a box as you can see on the pictures. Let me know what you think. :-) Best Regards from Zürich Switzerland. Dani 0 by Dani Brickzone, auf Flickr 0 2 by Dani Brickzone, auf Flickr 0-1 by Dani Brickzone, auf Flickr 0-3 by Dani Brickzone, auf Flickr 0-2 by Dani Brickzone, auf Flickr 0-5 by Dani Brickzone, auf Flickr 0-6 by Dani Brickzone, auf Flickr 0-4 by Dani Brickzone, auf Flickr 0-12 by Dani Brickzone, auf Flickr 0-13 by Dani Brickzone, auf Flickr 0-14 by Dani Brickzone, auf Flickr 0-7 by Dani Brickzone, auf Flickr 0-8 by Dani Brickzone, auf Flickr 0-9 by Dani Brickzone, auf Flickr 0-10 by Dani Brickzone, auf Flickr 0-11 by Dani Brickzone, auf Flickr 0-15 by Dani Brickzone, auf Flickr 0-16 by Dani Brickzone, auf Flickr 0-17 by Dani Brickzone, auf Flickr 0-18 by Dani Brickzone, auf Flickr 0-19 by Dani Brickzone, auf Flickr- 17 replies

-

- zürich

- switzerland

- (and 11 more)

-

[WIP] Mini Mining Excavator

teflon posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Hello there! I would like to show you a (slow and painful) progress on my take on mini mining excavator. Yeah, the Liebherr 9800 R kind. I kinda like the model, the 42100 and Markus is my favorite Technic creator but ... Well, the model is just to big and too simple and I can see some lazy short cuts (having three motors in an arm). And I haven't even mentioned the price, which is hilarious. Sorry about the rant. So you can imagine my joy when I saw cyberdyne systems' Mini Replica. He clearly showed what can be done in small form factor. However I was wondering if fully motorized version is also possible. Here starts my story. I've decided to build roughly 1/2 scale model. Yeah, I can be lazy to and dividing by 2 seems easy enough. At the moment I am not into esthetics, it's more about function, so please forgive me some crazy decision. Let me show you what have I done so far: I've started with the undercarriage. Simple, two tracks and turntable at the top. Well, the problem is motorization and even the smallest gearing needs 2-3 studs. The results is this: I am trying to use as little space for gearing as possible. It's not elegant by far: Motors are hidden in the back: At this stage, the battery (I am planing on using 2x BuWizz) will be located in the upper portion and cables are going through the center. Is not optimal solution, but solution through the turntable with mechanical connection needs even more space in the body. Next part was the bucket. I've also choosen 1/4 cylinder, however I've found interesting idea for bucket teeth. I think it works just fine: The bucket is fully operational. Next thing was building an arm. I was just trying to mimic the 42100 in 50% scale. However transfer of power at such scale is problematic: Here is the whole arm: And this is where I got stuck. I need to fix side M motors, which at the moment are just lying around. BuWizz units will be located at right corners. I am using studded technique just to approximate size. Another problems are universal joint's. They tend to work at angles 0-45°, however the arm swings for 90°. Maybe I should attach motors at an angle. Or do some gear magic. Regarding gear magic - I have to much of them already. I guess the biggest future problem is how to fit in motors and subcarriage. Feel free to comment.- 13 replies

-

- wip

- mining equipment

-

(and 2 more)

Tagged with:

-

[MOC] 42094 Alternate Builds

TGBDZ posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Long time no see! Some of You maybe remember my love for excavators and alternate models - 5 years ago I participated in the TC5 challange for alternate builds with an excavator and thanks to Your support I won the competition. Recently decided to challange myself again with the same task of creating an alternate model of the excavator using a middle sized set. 42094 was a no brainer as the best choice - tracks, turntable, some gears, mini actuator - most of the major components necessary for a successful build. The biggest problem was the lack of the wormgear - it would increase control and strength of the extended arm. Nevertheless, I found a solution, and in the end I'm pleasntly surprised how the MOC turned out. Functions: Working tracks (duhh) no suspension, no boogeys, more stable that way Upper structure rotates, sadly didn't manage to attach a knob, so it's done by grabbing the upper part Working boom similar to my previous build Possible to change the height of the whole boom Bucket and the second section of the arm works together - If You reach further, bucket opens, and vice versa - if the arm is getting closer the bucket closes Arm and boom function is operated by a black knob made from small sprocket pieces, to gain easier access, the rear can be opened. Both of the functions can be switched using a LBG connector that switches the clutch piece. So guys, what do You think? Also, what other alternates You would like to see made from this set? And If You want to get the LDD file than check Rebrickable or link below: MODEL INSTRUCTIONS Cheers!

.thumb.jpg.19742e89790e473128572b8d3969c36d.jpg)