-

Content Count

19 -

Joined

-

Last visited

About npicard

Spam Prevention

-

What is favorite LEGO theme? (we need this info to prevent spam)

Technic

-

Which LEGO set did you recently purchase or build?

42100 - Liebherr R 9800

Profile Information

-

Gender

Male

-

Interests

Mechs, mechanical computing, clockwork automata

Extra

-

Country

Canada

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

[TC21] Technic Transforming Vehicle Contest - Information Topic (Extended to 31st)

npicard replied to Jim's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

TBP got four functions out of one motor. If he can do that, I'm sure you can get four from two! -

Lego GBC Vertical Train Module

npicard replied to sawyer klegr's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Brilliant! This looks great and seems to work well too. As for the effect at the beginning of the video, I thought it was convincing. Nice video editing. :) As the cart reached its destination, I noticed a little wobble, but that just makes it look like the train track is a cantilever. There's no hint that it's vertical that I can see. -

npicard's small mechanisms

npicard replied to npicard's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

For this (small?) mechanism, I had the following design spec: there should be eight output axles, and they should be powered one at a time, so only one is turning at a given time. (For those following the larger project, this is the clock, part of a computer processor that provides timing for all the other parts. It's like the conductor of the orchestra.) Over the course of 8 or so prototypes, I came up with a system which had two pairs of Chiron shifters connected to two driving rings each. The idea was that I'd power the left side and right side alternately. However, I realized that I could just fold the two pairs of shifters into one. I've never seen four driving rings placed in a square around one Chiron shifter before. I'd be interested to hear if anyone has used this in a build before! In my final build, power goes into the two blue axles (simultaneously, in the same direction). The outputs are the eight pink gears. Every time the bottom shifter turns 180 degrees, the mechanism switches from powering the North and West output axles to powering the South and East axles. Meanwhile, every quarter turn of the top shifter changes which of the four gears is powered, either on the left or the right, depending on which is powered. To get all the switching to line up, the bottom shifter should make a quarter turn for every half turn of the top shifter. This way North, South, East, and West each get a turn in the output axles on the left, before power is shifted to the right. After a full cycle, all eight gears are given an equal turn being powered. Of course, the mechanism needs connective tissue for structure, to provide input power, to turn the shifters, to keep them aligned on 90 degree increments, and to gear down the motor. I used a PU XL motor geared down by 1:64 for the power and 1:1536 for the shifting. Just for completeness, this means each output gear turns 24 times before switching and the whole cycle takes a little less than 5 minutes. In researching for this build, I was really surprised that I couldn't find any sequential gearboxes that "wrapped back around." As in, 1-2-3-4-1-2-3-4... They all seem to go sequentially up, then back down. Hopefully it goes without saying that the eight outputs in this mechanism could be connected to different gearing ratios and then unified afterwards. This would create a sequential 8-speed gearbox that wraps around from 8th gear back to 1st gear. As far as I can tell, this is a totally novel mechanism. If I'm wrong and it's been done before, I would really appreciate seeing another approach! -

npicard's small mechanisms

npicard replied to npicard's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Nice! But how is it that the shuttle doesn't get caught on the teeth of the z24 gear? It always seems to be a problem for my builds, so whenever I've needed a shuttle structure, I've resorted to the 1L worm gear. (A poor solution, since it has friction.) It almost looks like the worm gear and the z24 gear are under-engaged, and the z24 gear and the z8 gear are over-engaged. Is that the case? And is it deliberate? If it's not the case, how did you solve the catching problem? Thanks for sharing. -

npicard's small mechanisms

npicard replied to npicard's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

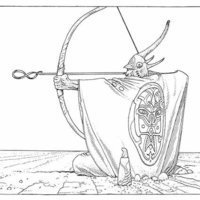

Here's a WIP: a functional 3-bit adder. It takes 3 booleans (represented by the red axles rotating either clockwise or counterclockwise, on the far right side in the pic) and outputs a 2-digit binary number representing the sum of those three booleans (near left side). Unfortunately, you can't see how it works due to it being too densely built. Ultimately, I'll probably end up doing a series of videos explaining the principles behind it. -

npicard's small mechanisms

npicard replied to npicard's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

It's actually a very good question. I suspect most people won't care at all. In my application, a demultiplexer will send power to only one logic gate out of a parallel bank of logic gates, then their outputs will all be joined together, so that the input to the demux has logic applied to it and is then output to one axle. When the logic gates are all joined directly, the one selected by the demux will drive the final output, but will also drive all the other logic gates backwards. Their inputs will be neutral since they were not selected by the demux. If none of this makes sense, I suppose you'll have to wait for my final design to be revealed! Suffice to say that dozens of these will be driven backwards at one time. Friction is at an absolute premium. -

npicard's small mechanisms

npicard replied to npicard's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

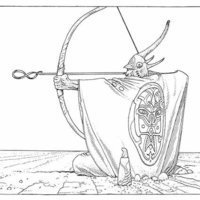

Thanks for all the nice messages, everyone. If anyone gets any use from my mechanisms, I'm happy. Here is what I mentioned a few days ago, and AND gate. If both green inputs are rotated clockwise (representing "1"), the pink output rotates clockwise as well. But if either (or both) of the green inputs are rotated counterclockwise (representing "0"), then the pink output will rotate counterclockwise. I have gone through about ten revisions to get it this small, reliable, and low-friction. Unfortunately, it still has high-friction moments when the green inputs are neutral and the pink output is driven (i.e. the mechanism is run in reverse). And it can always be smaller. :) -

npicard's small mechanisms

npicard replied to npicard's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I find components with axle holes but no friction incredibly interesting and useful. I'm always glad to hear of mechanisms using them and I'd love to see yours. As far as I know, there's only the 2L worm gear, the red z8 gear, and the changeover catch. Does anyone know of any other "loose" axle connections? I'm making a fully mechanical computer. It's my high-level design is close to final, but there are a lot of details to work out. To illustrate a small piece of it, if you combine my rotational driving ring selector and my two-way-to-one-way, you get a logic gate. The final result should have around 100 logic gates, along with a lot of other "connective tissue." I've been at it for four months and I'm currently estimating it will take me 2-3 years. -

npicard's small mechanisms

npicard replied to npicard's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Thank you! That would achieve basically the same result. However, my final build will have dozens of driving rings and I want my techniques to be universally applicable. I am not willing to modify or damage any parts to make it work. Of course, that's just me. To each their own! -

npicard's small mechanisms

npicard posted a topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

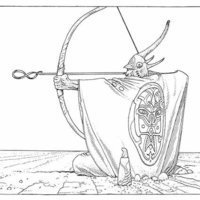

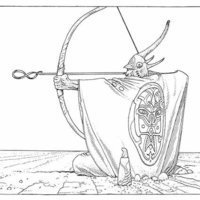

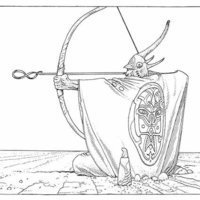

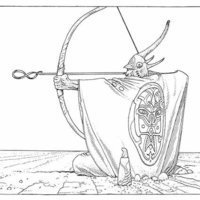

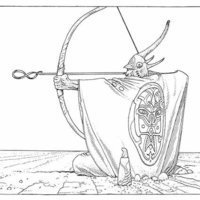

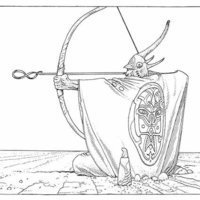

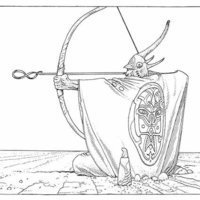

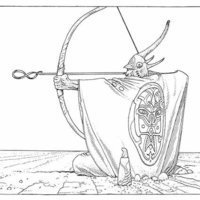

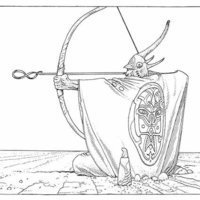

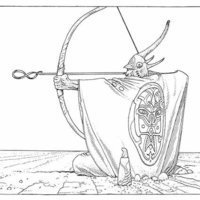

I am working on a very large-scale project, but I keep coming up with small mechanisms along the way that may be useful to others. I plan on using this thread to collect them. Of course, I stand on the shoulders of giants, and most of my mechanisms are merely refinements of the work of others. I'll credit where I can. As I'm new to this forum, I might take this space to briefly introduce myself. I built a lot of Mindstorms as a teenager in the RCX days. Then I had my dark ages from around 2007 until 2019. I decided to get back into it and purchased the 42100 Liebherr 9800. I'm mostly just interested in functional mechanisms. Two-way to one-way converter a.k.a. one-direction output This is is a mechanism that takes rotation in either direction as input (green) and outputs rotation in only one direction, no matter what the input direction was. In this configuration, the red axle only outputs counter-clockwise rotation. Swap red and grey for clockwise output. Inspiration came from this page: https://www.instructables.com/member/Jorbs3210/ I have seen and tested many of these mechanisms, but none that I found met my three biggest constraints: works in any orientation (doesn't rely on gravity) very low-friction (so, no rubber bands, no friction pins for idler gears, and not too many gears in total) if the input is in neutral and the output is being driven, it won't bind up This final constraint is the downfall of most other solutions. If you rotate the output axle, gears will bind together and the whole thing will lock up. In my solution, the white 3L liftarm touches the studs of the grey 1x2 plate during operation. This prevents the gears from over-engaging, meaning they can't bind no matter which axle is driven. This has a nice bonus effect of keeping friction low. Rotational driving ring selector This mechanism takes constant rotation as input (green) and, based on whether it is clockwise or counter-clockwise, selects between two states of a driving ring. The benefit of this system is if the input is connected to a powertrain that is also doing other things, so it can't be "turned off" when the correct gear is chosen. When you turn the input clockwise, the blue worm gear travels forward and eventually hits the light grey stop. Then it begins to turn the z8 gear, which turns the white 2L liftarm, which flips the red changeover catch. This is based off of Sariel's pneumatic autovalve: http://sariel.pl/2008/12/pneumatic-autovalve/ @Keegan Pilling suggested Sariel's solution. I just worked out the details. Low-friction driving ring axle In the previous mechanism, I found that the white driving ring axle (that keeps it engaged with clutch gears with a "click") is too high-friction. The input needs to be fairly high torque. Unfortunately, the zero-friction 3L axle connector doesn't keep the driving ring in place at all. I was seeking a solution that was a balance between the two, providing just enough friction to keep the driving ring engaged with the clutch gear, and no more. @2GodBDGlory provided the idea of using a 2L axle connector with a 3L 3.18 bar. I found it paired well with a 3/4 pin. I hope these are helpful for someone! I'll post more as they occur to me. -

[HELP] Generic Building Help Topic

npicard replied to Jim's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Update: this solution doesn't work as-is for a surprising reason. The 3L bar is exactly 3L. The 3673 Frictionless Pin has a stop in the very centre, so the 3L bar can't actually go 1L into it. It can go something like 0.95L into it. This means the whole assembly (pin, 3L bar, and axle connector) are very slightly over 5L – around 5.05L. This matters because the axle connector presses up against the red clutch gear, creating friction with it. In my application, the red clutch gear next to the axle connector sometimes turns in the opposite direction as the powertrain axle on which it spins. The resulting friction is doubled and we lose all our gains from the entire solution. However, a very simple modification saves it: replace the 3673 Frictionless Pin with the 32003 Pin 3/4. It allows a 3.18 bar to pass as deep into it as you like. This solution requires mounting the entire axle with a thin liftarm on that end. I actually ended up mounting it with a 44 Axle and Pin Connector Toggle Joint Smooth. It's now working perfectly and I'll happily mark this help request resolved. -

[HELP] Generic Building Help Topic

npicard replied to Jim's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Nice solution. I'll have to dig through my unsorted System to find a 3L bar, but unless anyone can come up with something better, I'll probably go with this. Thanks! @Keegan Pilling I haven't forgotten about you! I won't be surprised if you pull something out of your hat. -

[HELP] Generic Building Help Topic

npicard replied to Jim's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

I realized I can solve the problem of the incomplete engagement due to the O-end of the bush in another way: by shortening the relevant white paddle. This would require a part that has an axle hole and a protrusion that is only around 1.75L. My first thought was the 49283 Axle and Wire Connector, but unfortunately it's more like 1.95L and suffers from the same problem as the 2L liftarm. My second thought was the 24122 Lightsaber Hilt. Unfortunately, its protrusions are exactly 0.5L each, making it effectively a 1.5L liftarm for the purposes of this problem. It's too short and doesn't engage the changeover catch! Even 1mm more length would make it perfect for the job. Still no perfect solution. Best one yet is 2God's version with the new white pin and a 3L bar. -

[HELP] Generic Building Help Topic

npicard replied to Jim's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Thanks for both of your responses. I've tested out 2GodBDGlory's suggestion and the friction is pretty much what I'm looking for. I don't need torque transmission through the powertrain axle, so that's fortunately not a problem for me. The only real issue is the funny 4L bar sticking out the end. It's not very aesthetic, but it absolutely gets the job done. :) (Edit: Another minor issue is the friction on the black 18651 Axle 2L with Pin. A third minor issue is the friction is a little high, see below.) (Edit 2: I just learned about the white 65249 Axle 2L with Pin without Friction. I don't own this part as it's new this year. It seems exceedingly useful!) Keegan Pilling, your suggestion of using a 6590 bushing is good. In fact, it actually improves this solution by reducing the friction. The reason is, 2God's setup as-is allows the springs in the driving ring to "dip" closer to the black axle portion. When you move it back to the left, it has to "overcome" this dip. High-friction for a moment. The bushing prevents it from ever falling into the dip. HOWEVER, the bushing has that pesky O-shaped end. This prevents the driving ring from fully engaging with the clutch gear on the right. This isn't a problem for clutch strength or torque transmission or anything, and most people probably wouldn't care. (It's less than a quarter module error.) However, in my build, the white paddles need clearance to continue their circular path. The tiny error introduced by the O-end of the bushing actually prevents them from clearing the changeover catch. So, KP's modification of 2God's solution would solve my problem perfectly if it weren't for the asymmetry of the 1L bushing. -

npicard changed their profile photo

npicard changed their profile photo

-

[HELP] Generic Building Help Topic

npicard replied to Jim's topic in LEGO Technic, Mindstorms, Model Team and Scale Modeling

Yes, exactly. Exactly. Here's a picture. Select gear by driving bottom axle. Depending on direction, the worm gear travels to the correct z8 gear which drives the white "paddles," which in turn flip the changeover catch. No constant pressure, since the white paddle just keeps spinning until the input axle changes direction. [edit: image removed] Edit: as you can see, I used your suggestion for Sariel's pneumatic autovalve. It worked perfectly and is very reliable. It didn't fit all of my constraints, but it was such a good solution that I solved them in another way. I do. I guess I could come up with a new system to have the worm gear select between states. That requires a half-turn though, so I really don't know how I'd approach that. Those little paddles sure won't do it! This subsystem will actually experience very little load. The problem is that a lot of torque is taken up elsewhere, so there's not a lot to share. (As in, sometimes a motor will be switching many of these at one time.) So torquing up will mean a lot of stress "upstream." That's why I'm looking for a solution that puts almost zero load on the motor. Thanks for the thoughts so far.