npicard's small mechanisms

I am working on a very large-scale project, but I keep coming up with small mechanisms along the way that may be useful to others. I plan on using this thread to collect them.

Of course, I stand on the shoulders of giants, and most of my mechanisms are merely refinements of the work of others. I'll credit where I can.

As I'm new to this forum, I might take this space to briefly introduce myself. I built a lot of Mindstorms as a teenager in the RCX days. Then I had my dark ages from around 2007 until 2019. I decided to get back into it and purchased the 42100 Liebherr 9800. I'm mostly just interested in functional mechanisms.

Two-way to one-way converter

a.k.a. one-direction output

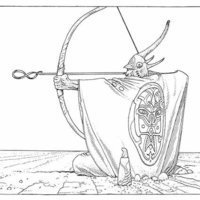

This is is a mechanism that takes rotation in either direction as input (green) and outputs rotation in only one direction, no matter what the input direction was. In this configuration, the red axle only outputs counter-clockwise rotation. Swap red and grey for clockwise output.

Inspiration came from this page: https://www.instructables.com/member/Jorbs3210/

I have seen and tested many of these mechanisms, but none that I found met my three biggest constraints:

works in any orientation (doesn't rely on gravity)

very low-friction (so, no rubber bands, no friction pins for idler gears, and not too many gears in total)

if the input is in neutral and the output is being driven, it won't bind up

This final constraint is the downfall of most other solutions. If you rotate the output axle, gears will bind together and the whole thing will lock up. In my solution, the white 3L liftarm touches the studs of the grey 1x2 plate during operation. This prevents the gears from over-engaging, meaning they can't bind no matter which axle is driven. This has a nice bonus effect of keeping friction low.

Rotational driving ring selector

This mechanism takes constant rotation as input (green) and, based on whether it is clockwise or counter-clockwise, selects between two states of a driving ring. The benefit of this system is if the input is connected to a powertrain that is also doing other things, so it can't be "turned off" when the correct gear is chosen.

When you turn the input clockwise, the blue worm gear travels forward and eventually hits the light grey stop. Then it begins to turn the z8 gear, which turns the white 2L liftarm, which flips the red changeover catch.

This is based off of Sariel's pneumatic autovalve: http://sariel.pl/2008/12/pneumatic-autovalve/

@Keegan Pilling suggested Sariel's solution. I just worked out the details.

Low-friction driving ring axle

In the previous mechanism, I found that the white driving ring axle (that keeps it engaged with clutch gears with a "click") is too high-friction. The input needs to be fairly high torque. Unfortunately, the zero-friction 3L axle connector doesn't keep the driving ring in place at all. I was seeking a solution that was a balance between the two, providing just enough friction to keep the driving ring engaged with the clutch gear, and no more.

@2GodBDGlory provided the idea of using a 2L axle connector with a 3L 3.18 bar. I found it paired well with a 3/4 pin.

I hope these are helpful for someone! I'll post more as they occur to me.